To accurately evaluate high-entropy alloys (HEAs), a heating device is required to simulate the extreme service environments for which these materials are designed. By integrating a heating system controlled by an optical pyrometer, researchers can perform in-situ indentation tests at temperatures up to 800 °C. This capability is critical because it is the only method to verify the hardness retention advantages of HEAs compared to traditional alloys under actual operating conditions.

Standard room-temperature testing fails to capture the defining advantage of high-entropy alloys: their stability in extreme heat. Integrating a heating device enables in-situ verification of hardness retention at service temperatures, validating the material's performance where it matters most.

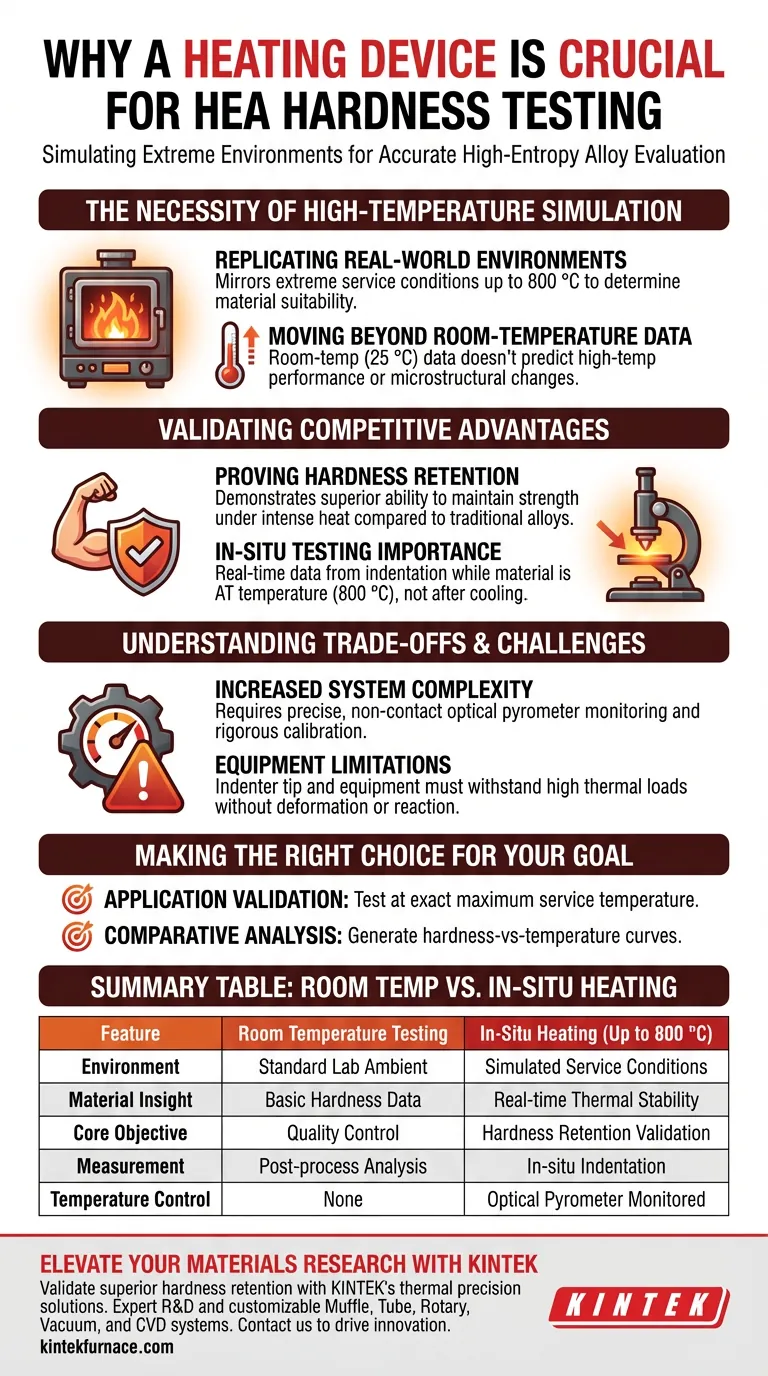

The Necessity of High-Temperature Simulation

Replicating Real-World Environments

High-entropy alloys are frequently engineered for use in extreme environments where standard materials fail.

To determine if an HEA is suitable for a specific application, the testing conditions must mirror the service conditions.

The heating device allows the macro-hardness tester to elevate the sample temperature up to 800 °C, effectively simulating the thermal stress the material will face in the field.

Moving Beyond Room-Temperature Data

Mechanical properties measured at room temperature (approx. 25 °C) are poor predictors of performance at elevated temperatures.

Most materials experience significant changes in microstructure and mechanical strength when heated.

Relying solely on ambient testing would miss critical failure points or degradation that only occurs under high thermal loads.

Validating Competitive Advantages

Proving Hardness Retention

The primary reason for developing HEAs is often their superior performance compared to traditional alloys.

Specifically, HEAs are noted for hardness retention—the ability to maintain their strength even when subjected to intense heat.

A heating device is required to empirically prove this advantage; without it, you cannot demonstrate that the HEA outperforms traditional counterparts under high-temperature conditions.

The Importance of In-Situ Testing

The setup described does not simply heat the material and then test it after it cools.

It performs in-situ indentation, meaning the mechanical force is applied while the material is currently at 800 °C.

This provides real-time data on how the alloy responds to physical stress while simultaneously under thermal stress.

Understanding the Trade-offs

Increased System Complexity

Integrating a heating stage turns a standard hardness test into a complex experiment.

The use of an optical pyrometer indicates a need for precise, non-contact temperature monitoring to ensure accuracy.

Any fluctuation in temperature control can skew the hardness data, requiring rigorous calibration.

Equipment Limitations

Testing at 800 °C places stress on the testing equipment itself, not just the sample.

The indenter tip must be capable of withstanding these temperatures without deforming or chemically reacting with the hot alloy.

Operators must ensure the macro-hardness tester is specifically rated for the thermal loads generated by the heating device.

Making the Right Choice for Your Goal

To maximize the value of your materials testing, align your evaluation method with your end goals:

- If your primary focus is application validation: Use the heating device to test at the exact maximum temperature (up to 800 °C) your component will face in service.

- If your primary focus is comparative analysis: Use in-situ heating to generate a hardness-vs-temperature curve, clearly demonstrating where traditional alloys fail and HEAs succeed.

By testing in the environment where the material lives, you move from theoretical potential to proven performance.

Summary Table:

| Feature | Room Temperature Testing | In-Situ Heating (Up to 800 °C) |

|---|---|---|

| Environment | Standard Lab Ambient | Simulated Service Conditions |

| Material Insight | Basic Hardness Data | Real-time Thermal Stability |

| Core Objective | Quality Control | Hardness Retention Validation |

| Measurement | Post-process Analysis | In-situ Indentation |

| Temperature Control | None | Optical Pyrometer Monitored |

Elevate Your Materials Research with KINTEK

To truly validate the superior hardness retention of high-entropy alloys, you need thermal precision that mirrors real-world service environments. KINTEK provides the cutting-edge heating solutions required for advanced materials testing. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized lab high-temp furnaces—all fully customizable to meet your unique research requirements.

Ready to prove your material's performance under extreme heat? Contact us today to discuss your custom furnace needs and see how our expertise can drive your innovation forward.

Visual Guide

References

- Laurent Peltier, Jérome Slowensky. Design of Multiphase Compositionally Complex Alloys for Enhanced Hardness at Elevated Temperatures and Machinability: Comparative Study with Inconel 718. DOI: 10.1002/adem.202501146

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role do high-temperature sintering furnaces play in ceramic SLA? Unlock 99% Density in 3D Printed Ceramics

- Why is crushed glass used as a sealing agent during siliconization? Optimize Your High-Temp Reaction Purity

- Why is graphene oxide (GO) essential in microwave synthesis? Unlock Rapid Growth and Precise 2D Nanocomposite Control

- Why is a high-precision furnace critical for refractory castables? Ensure Structural Integrity & Mineral Stability

- What advantages does hydrogen gas-phase pyrolysis offer over inert gas? Unlock Superior Carbon Defunctionalization

- What role does a drying oven play in the final preparation of graphite oxide powder? Ensure Material Stability and Purity

- What are the benefits of using advanced technology in heat treatment furnaces? Achieve Superior Material Quality and Efficiency

- What key process environments does a Molecular Beam Epitaxy (MBE) system provide? Optimize CaF2 Thin Film Growth