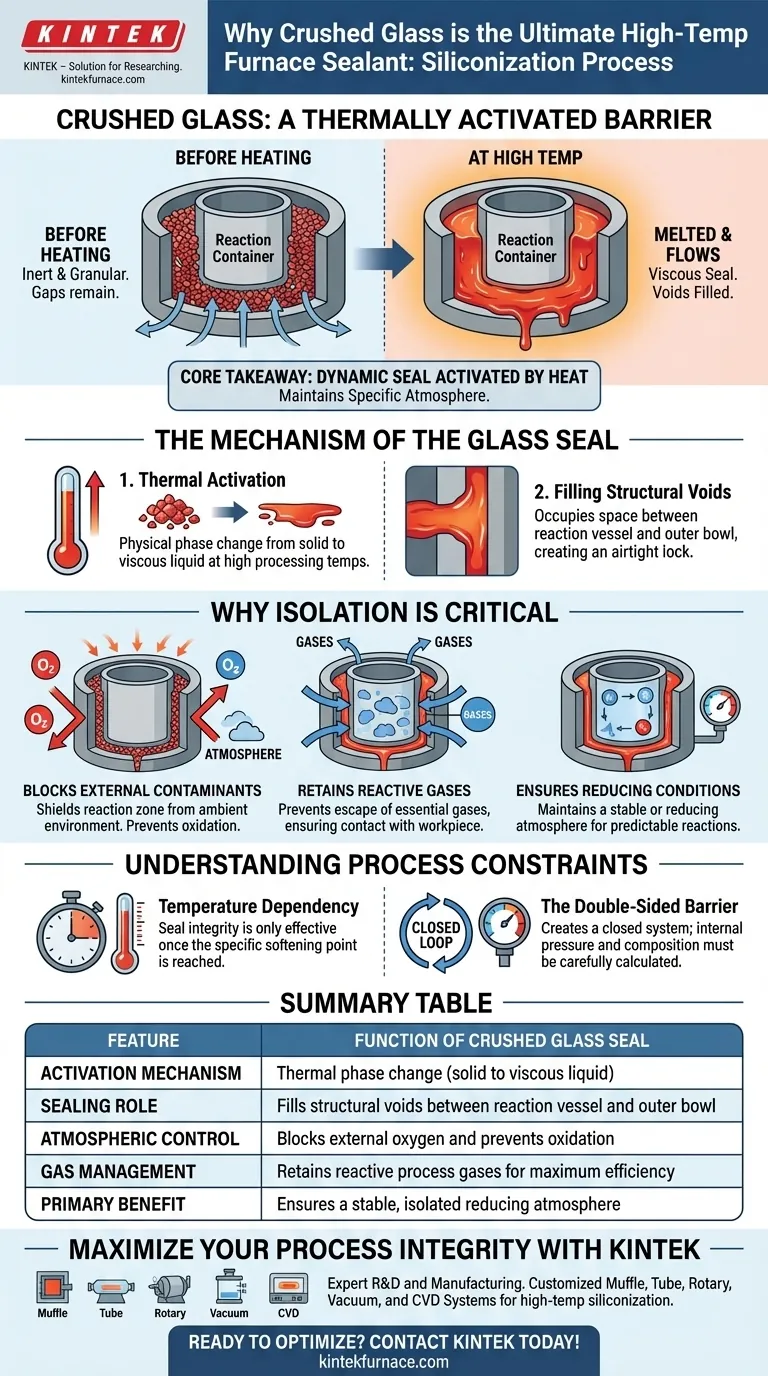

Crushed glass functions as a thermally activated barrier that hermetically seals reaction vessels during high-temperature siliconization. As the furnace heats up, the glass transitions from a solid to a viscous liquid, flowing into voids to create an airtight lock that isolates the chemical process from the surrounding environment.

Core Takeaway The primary role of crushed glass is to provide a dynamic seal that activates only at high temperatures. By melting into the gaps between the reaction container and the outer bowl, it maintains a specific atmospheric condition—keeping contaminants out and retaining essential reactive gases within the reaction zone.

The Mechanism of the Glass Seal

Thermal Activation

The sealing process relies entirely on the physical phase change of the glass. At room temperature, the crushed glass is inert and granular.

However, as the furnace reaches high processing temperatures, the glass particles soften and melt. This transition transforms the loose particles into a unified, viscous material.

Filling the Structural Voids

Once melted, the glass flows to fill the specific physical gaps in the assembly.

It occupies the space between the inner reaction container and the outer protective bowl. This effectively caulks the assembly, creating a continuous barrier where there was previously open space.

Why Isolation is Critical

Blocking External Contaminants

The most immediate function of the molten glass is to act as a shield against the furnace's ambient environment.

It strictly prevents the external atmosphere from entering the reaction zone. This is vital for maintaining purity, as external oxygen or other furnace gases could oxidize the silicon or disrupt the delicate chemical balance required for siliconization.

Retaining Reactive Gases

Equally important is the seal’s ability to act as a containment system.

The siliconization process generates or utilizes specific reactive gases. The molten glass prevents these gases from escaping the vessel, ensuring they remain in contact with the workpiece to facilitate the treatment.

Ensuring Reducing Conditions

By blocking entry and preventing escape, the glass allows the interior to maintain a stable or reducing atmosphere.

This stability is the foundational requirement for successful heat treatment, ensuring the chemical reactions proceed predictably without interference from fluctuating external conditions.

Understanding the Process Constraints

Temperature Dependency

It is important to note that this sealing method is not active at the start of the process.

The integrity of the seal is temperature-dependent. The protection only becomes effective once the furnace reaches the specific softening point of the glass used.

The Double-Sided Barrier

The seal creates a "closed loop" system. While this is beneficial for chemistry, it means the reaction zone is completely isolated.

Because the seal stops gases from escaping, the internal pressure and chemical composition must be carefully calculated, as the system cannot naturally vent excess pressure once the glass has melted.

Making the Right Choice for Your Goal

To optimize your high-temperature siliconization process, consider the following regarding the glass seal:

- If your primary focus is Atmosphere Purity: Ensure the glass volume is sufficient to fully bridge the gap between the inner and outer vessels to prevent external oxidation.

- If your primary focus is Reaction Efficiency: Rely on the seal to trap reactive gases, maximizing their dwell time and contact with the material being treated.

Ultimately, the use of crushed glass provides a simple yet highly effective method to guarantee the atmospheric integrity required for precise chemical heat treatments.

Summary Table:

| Feature | Function of Crushed Glass Seal |

|---|---|

| Activation Mechanism | Thermal phase change (solid to viscous liquid) |

| Sealing Role | Fills structural voids between reaction vessel and outer bowl |

| Atmospheric Control | Blocks external oxygen and prevents oxidation |

| Gas Management | Retains reactive process gases for maximum efficiency |

| Primary Benefit | Ensures a stable, isolated reducing atmosphere |

Maximize Your Process Integrity with KINTEK

Achieving the perfect hermetic seal is critical for high-temperature siliconization. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be fully customized to meet your unique atmospheric and thermal requirements. Whether you are scaling production or refining lab-scale heat treatments, our high-temp furnaces provide the precision and reliability your materials demand.

Ready to optimize your thermal processing? Contact us today to consult with our experts!

Visual Guide

References

- Nikita V. Lemeshko, Ruslan M. Tazetdinov. Production of silicon-based thermodiffusion layer in tube furnace coil weld after long-term operation. DOI: 10.1051/epjconf/202531801007

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the role of MgO powder in Nickel-Aluminum VCS? Achieve Precise Thermal Control & Powder Quality

- What are the core technical advantages of an industrial microwave sintering system? Gain Speed and Material Integrity

- Why maintain argon and oxygen control in Titanium LMD? Ensure Peak Purity for Your High-Performance Components

- Why is precise temperature control essential for carbon material synthesis? Achieve Superior Purity and Microstructure

- What is Joule Heating and how does it relate to induction heating? Master the Physics of Contactless Heating

- How does a high-precision infrared temperature measurement system influence the sintering quality of Al2O3/TiC ceramics?

- Why is the base vacuum level of a magnetron co-sputtering system critical for Ru50Mo50(0001) alloy thin films?

- Why must high-purity nitrogen be used for biochar activation? Ensure Carbon Integrity and Pore Development