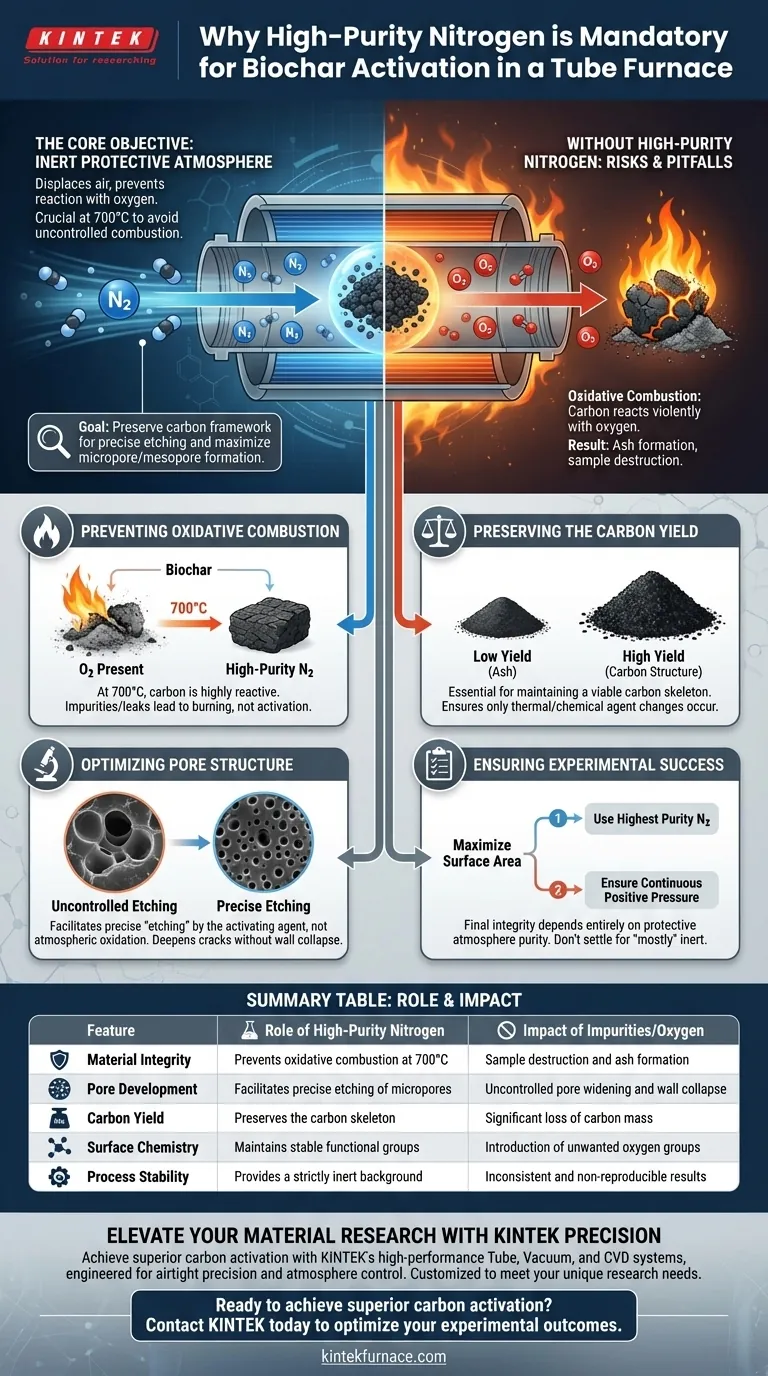

A high-purity nitrogen source is mandatory to establish a strictly inert protective atmosphere within the tube furnace. By displacing air, nitrogen prevents the biochar from reacting with oxygen during the high-temperature treatment, which is critical for successful activation.

The Core Objective At 700 °C, carbon is highly reactive; without an inert nitrogen shield, biochar will undergo uncontrolled combustion rather than activation. High-purity nitrogen ensures the carbon framework is preserved, allowing the activating agent to precisely etch the material and maximize the formation of essential micropores and mesopores.

The Critical Role of Atmosphere Control

Preventing Oxidative Combustion

The most immediate risk during biochar activation is oxidative combustion. At the activation temperature of 700 °C, carbon reacts violently with oxygen.

If the furnace atmosphere contains oxygen (due to low-purity gas or leaks), the biochar will simply burn. This results in the complete destruction of the sample, leaving behind only ash rather than activated carbon.

Preserving the Carbon Yield

To obtain a usable product, the carbon skeleton must survive the heat. High-purity nitrogen ensures that the only chemical changes occurring are those driven by the thermal energy and the specific activating agent.

This preservation of the carbon mass is essential for maintaining a viable carbon yield at the end of the process.

Optimizing Pore Structure

Facilitating Precise Etching

Chemical activation is designed to be a subtractive process, effectively "etching" the carbon. The activating agent eats away specific parts of the carbon structure to create internal voids.

This process requires a stable, non-reactive background environment. Nitrogen provides this stability, ensuring that the etching process is controlled solely by the chemical agent, not by random atmospheric oxidation.

Developing Micropores and Mesopores

The ultimate goal of activation is increasing surface area. The protective nitrogen atmosphere allows the activating agent to deepen cracks and crevices without collapsing the surrounding walls.

This controlled environment is what enables the maximization of micropores and mesopores. These structures are responsible for the biochar's high performance in filtration and adsorption applications.

Common Pitfalls and Risks

The Danger of Low-Purity Sources

Using industrial-grade nitrogen with trace oxygen impurities can compromise the surface chemistry of the biochar. Even slight oxidation can alter the functional groups on the surface, changing how the material interacts with pollutants or fluids later.

"Good Enough" is Often Insufficient

Operators sometimes assume that a "mostly" inert atmosphere is sufficient. However, at 700 °C, even small leaks or impurities act as contaminants that degrade the structural integrity of the pores you are trying to create.

Ensuring Experimental Success

To achieve high-performance biochar, your gas selection must align with your structural goals.

- If your primary focus is maximizing surface area: Use the highest purity nitrogen available to prevent oxidative erosion from widening pores uncontrollably.

- If your primary focus is process consistency: Ensure your gas flow provides a continuous positive pressure to prevent outside air from diffusing into the tube furnace.

The integrity of your final carbon structure is entirely dependent on the purity of your protective atmosphere.

Summary Table:

| Feature | Role of High-Purity Nitrogen | Impact of Impurities/Oxygen |

|---|---|---|

| Material Integrity | Prevents oxidative combustion at 700°C | Sample destruction and ash formation |

| Pore Development | Facilitates precise etching of micropores | Uncontrolled pore widening and wall collapse |

| Carbon Yield | Preserves the carbon skeleton | Significant loss of carbon mass |

| Surface Chemistry | Maintains stable functional groups | Introduction of unwanted oxygen groups |

| Process Stability | Provides a strictly inert background | Inconsistent and non-reproducible results |

Elevate Your Material Research with KINTEK Precision

Don't let atmospheric contamination compromise your biochar yield or pore structure. KINTEK’s high-performance Tube, Vacuum, and CVD systems are engineered to provide the airtight precision and atmosphere control required for sensitive chemical activation processes. Backed by expert R&D and manufacturing, our laboratory high-temperature furnaces are fully customizable to meet your unique research needs.

Ready to achieve superior carbon activation? Contact KINTEK today to discover how our advanced furnace technology can optimize your experimental outcomes.

Visual Guide

References

- Salem S. Bamerdhah, Mohammad Asif. Optimized synthesis of activated carbon from date palm seeds for efficient crude oil adsorption in wastewater treatment. DOI: 10.1038/s41598-025-16831-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vacuum drying oven contribute to the study of the hydration degree in cement pastes? Essential Lab Insights

- What is the primary function of an industrial drying oven for GBC? Achieving Material Standardization and Quality

- Why do substrates undergo treatment in a high-temperature annealing furnace? Perfecting PtTe2/WTe2 Heterostructures

- What role does thermal processing with precise temperature control and tensile stress play in PVDF fiber stabilization?

- What is the purpose of pre-drying SiO2 raw materials at 400 degrees Celsius? Ensure Precise Stoichiometric Synthesis

- What is the operating principle of a vacuum freeze-dryer in the fabrication of carbon aerogels? Master Sublimation

- How does microstructural observation assist in optimizing LATP sintering? Master High-Density Material Processing

- What is the function of a Mass Flow Controller (MFC)? Achieve Precise Ethanol Vapor Delivery for Graphene Synthesis