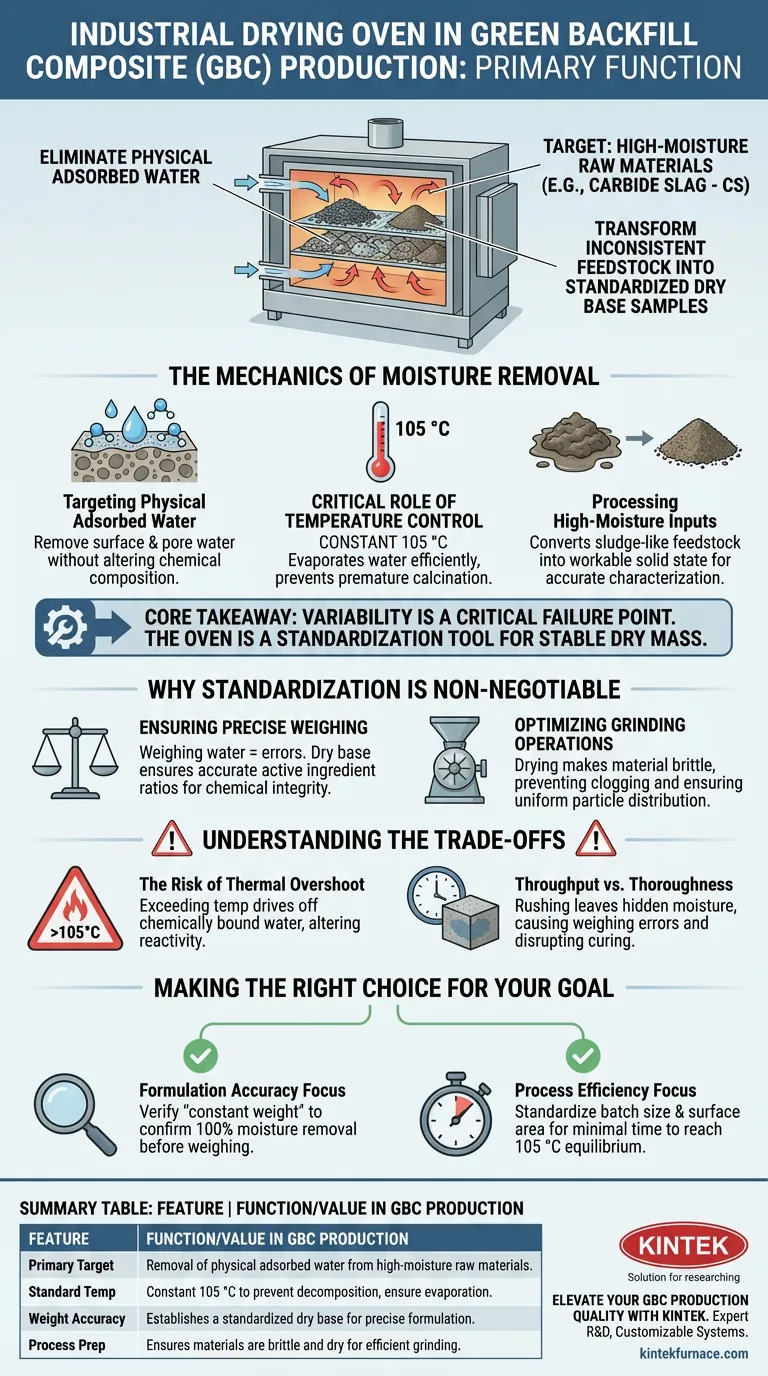

The primary function of an industrial drying oven in Green Backfill Composite (GBC) production is to eliminate physical adsorbed water from high-moisture raw materials. Specifically targeting inputs like carbide slag (CS), the oven operates at a constant temperature (typically 105 °C) to transform inconsistent feedstock into standardized dry base samples, which is a prerequisite for accurate processing.

Core Takeaway: Variability in raw material moisture content is a critical failure point in composite manufacturing. The industrial drying oven acts as a standardization tool, ensuring that all subsequent weighing and grinding operations are based on a stable dry mass rather than fluctuating wet weight.

The Mechanics of Moisture Removal

Targeting Physical Adsorbed Water

Raw materials used in GBC, particularly industrial by-products, often retain significant amounts of moisture on their surface and within their pore structures.

The drying oven is specifically engineered to remove physical adsorbed water. This is distinct from chemically bound water; the goal is to dry the material without altering its fundamental chemical composition.

The Critical Role of Temperature Control

Precision is key to this operation. The oven maintains a specific constant temperature, cited in standard protocols as 105 °C.

This temperature is sufficient to evaporate water efficiently but is generally low enough to prevent premature calcination or thermal decomposition of the raw minerals.

Processing High-Moisture Inputs

Materials such as carbide slag (CS) are naturally high in moisture content when sourced.

Without immediate and thorough drying, these materials are difficult to handle and impossible to characterize accurately. The oven converts this sludge-like or damp feedstock into a workable solid state.

Why Standardization is Non-Negotiable

Ensuring Precise Weighing

In composite formulation, ratios are everything. If you weigh raw materials that still contain water, you are effectively weighing the water, not the active ingredient.

Drying provides a standardized dry base. This ensures that when a recipe calls for a specific weight of carbide slag, you are adding that exact amount of material, ensuring the chemical integrity of the final backfill composite.

Optimizing Grinding Operations

Subsequent steps in GBC production often involve grinding materials to a specific particle size.

Grinding damp materials is inefficient and can damage equipment due to clogging or "caking." Thorough drying ensures the material is brittle and ready for efficient grinding, resulting in a uniform particle distribution.

Understanding the Trade-offs

The Risk of Thermal Overshoot

While removing water is essential, exceeding the target temperature (e.g., going significantly above 105 °C) can introduce errors.

Excessive heat may drive off chemically bound water or volatiles that should remain in the structure. This alters the reactivity of the material before it even enters the mixing phase.

Throughput vs. Thoroughness

There is always a balance between processing speed and drying completeness.

Rushing the drying cycle to increase throughput can leave residual moisture in the center of the material bulk. This "hidden" moisture will reintroduce weighing errors and potentially disrupt the curing process of the GBC later on.

Making the Right Choice for Your Goal

To ensure the highest quality Green Backfill Composite, apply the following principles to your pretreatment workflow:

- If your primary focus is Formulation Accuracy: Prioritize verifying the "constant weight" of your samples after drying to confirm 100% moisture removal before weighing.

- If your primary focus is Process Efficiency: Standardize the batch size and surface area of the carbide slag inside the oven to minimize the time required to reach the 105 °C equilibrium.

By viewing the drying oven not just as a heater, but as a critical instrument for material standardization, you secure the foundation of your entire production line.

Summary Table:

| Feature | Function/Value in GBC Production |

|---|---|

| Primary Target | Removal of physical adsorbed water from high-moisture raw materials (e.g., carbide slag). |

| Standard Temp | Constant 105 °C to prevent chemical decomposition while ensuring complete evaporation. |

| Weight Accuracy | Establishes a standardized dry base for precise formulation and chemical integrity. |

| Process Prep | Ensures materials are brittle and dry for efficient, clog-free grinding operations. |

Elevate Your GBC Production Quality with KINTEK

Precise pretreatment is the foundation of high-performance Green Backfill Composites. At KINTEK, we understand that thermal accuracy is non-negotiable for your lab and industrial workflows.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized high-temperature lab furnaces. Whether you need to standardize high-moisture carbide slag or require a custom solution for advanced material synthesis, our equipment is fully customizable to meet your unique processing needs.

Ready to optimize your material standardization? Contact KINTEK Today to Consult Our Experts

Visual Guide

References

- Jianmin Li, Kai Wang. Study on the synergistic hydration mechanism of granulated blast furnace slag-carbide slag-based cementitious materials and the properties of full-solid waste backfill materials. DOI: 10.1038/s41598-025-86509-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is precise temperature control in an aging oven critical for ZK61 alloys? Master the 175°C Pre-aging Threshold

- What are the key advantages of using an annealing furnace? Enhance Material Quality and Manufacturing Efficiency

- What is the significance of the vacuum oven drying process in the preparation of MnO@WAC electrode sheets? Expert Guide

- What is graphite furnace atomic absorption spectroscopy used for? Detecting Trace Elements at Parts-Per-Billion Levels

- What is a benchtop industrial oven? Maximize Space and Efficiency in Your Lab

- What is the importance of cold traps and pump recovery systems in VTD? Boost Safety and Material Recycling

- How does a gas evolution analysis system monitor gas release? Optimize Your Casting Integrity

- What role does a high-temperature annealing furnace play in the preparation of AAO substrates? Enhance Pore Regularity