At its core, an annealing furnace is used to fundamentally alter a material's internal structure to relieve stress, improve softness and ductility, and refine its grain structure. This process corrects structural defects introduced during manufacturing steps like casting or welding, making the material easier to work with and more predictable in its final application.

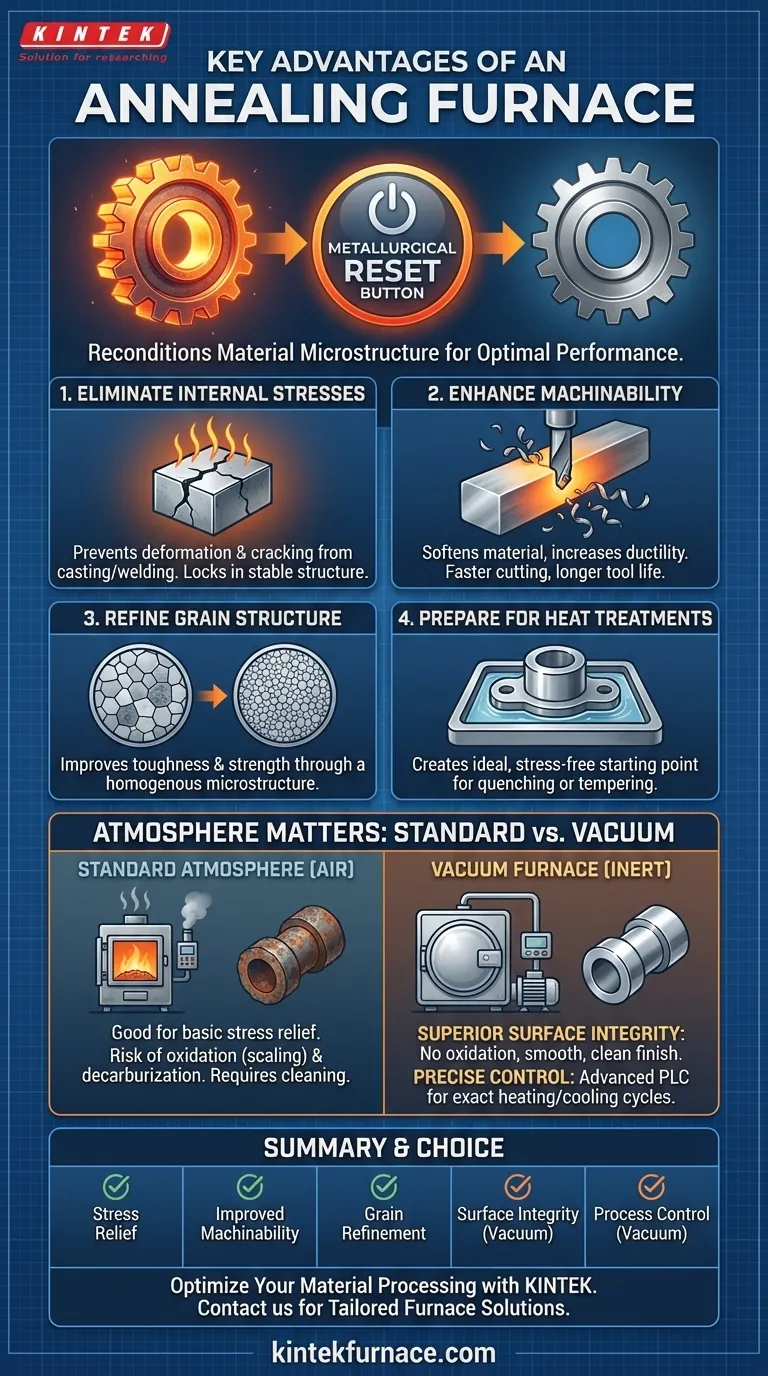

The true value of an annealing furnace is not just in what it does—soften metal—but in why it does it. It serves as a critical metallurgical reset button, correcting internal damage from previous fabrication steps and preparing the material for optimal performance in subsequent processes.

The Core Purpose: Reconditioning the Material's Microstructure

Annealing is not a single action but a controlled process of heating and cooling. Its primary function is to manipulate the material's crystalline structure, known as its microstructure, to achieve desirable properties.

Eliminating Internal Stresses

Processes like casting, forging, rolling, and welding introduce significant internal stresses into a material. If left untreated, these stresses can lead to unexpected deformation, warping, or even cracking over time.

An annealing furnace heats the material to a specific temperature where its atoms can rearrange themselves into a more stable, lower-energy state. The controlled slow cooling then "locks in" this stress-free structure.

Softening for Enhanced Machinability

Hard, brittle materials are difficult and expensive to cut, drill, or shape. This increases tool wear and can compromise the quality of the finished part.

Annealing softens the material and increases its ductility, drastically improving its machinability. This allows for faster cutting speeds, longer tool life, and a better surface finish, directly reducing manufacturing costs.

Refining Grain Structure

The mechanical properties of a metal, such as its toughness and strength, are directly tied to the size and uniformity of its crystal grains. Coarse or inconsistent grains can create points of weakness.

The annealing process can be tailored to refine the grain structure, resulting in a more homogenous and robust material with improved mechanical properties.

Preparing for Subsequent Heat Treatments

Annealing is often an intermediate step. It is used to create a uniform, stress-free microstructure that provides the ideal starting point for final heat treatments like quenching or tempering, which impart hardness and strength. Without proper annealing first, these later processes would be far less effective and predictable.

The Impact of Environment: Air vs. Vacuum Annealing

The atmosphere inside the furnace plays a critical role in the final quality of the workpiece. This is the primary distinction between standard atmosphere furnaces and modern vacuum furnaces.

The Standard Approach: Atmosphere Furnaces

In a standard furnace, the material is heated in the presence of air or a controlled gas mixture. While effective for achieving the microstructural changes described above, this environment allows for reactions on the material's surface.

This can result in oxidation (scaling) and decarburization (loss of carbon from the surface of steels), which may require secondary cleaning processes like sandblasting or pickling.

The Vacuum Advantage: Superior Surface Integrity

A vacuum annealing furnace removes virtually all atmospheric gases from the heating chamber. This inert environment prevents surface reactions entirely.

The result is a workpiece with a smooth, bright, and clean surface, free from oxidation. This is critical for high-value components where surface finish is paramount, as it eliminates the need for costly and time-consuming secondary cleaning.

The Vacuum Advantage: Unmatched Process Control

Modern vacuum furnaces are equipped with advanced PLC (Programmable Logic Controller) systems. These provide exceptionally precise control over heating rates, holding times, and cooling profiles.

This level of control ensures high repeatability from batch to batch and allows for the execution of complex annealing cycles to meet very specific material property requirements.

Understanding the Trade-offs

While powerful, annealing is a process with specific goals and limitations. Understanding its place relative to other heat treatments is key to using it effectively.

Annealing vs. Normalizing vs. Tempering

These terms are often confused but describe distinct processes. Annealing produces the softest, most ductile state through very slow cooling. Normalizing uses air cooling to create a harder, stronger state. Tempering is a low-temperature process used to reduce the brittleness of a quenched part. Choosing the right one depends entirely on the desired final properties.

The Cost of a Perfect Surface

A vacuum furnace provides superior surface quality and process control, but it represents a higher capital investment compared to a standard atmosphere furnace. The decision to use a vacuum furnace must be justified by the need for a pristine surface finish and the avoidance of secondary cleaning operations.

Cycle Time is a Factor

The controlled, slow cooling required for a full anneal is inherently time-consuming. This can be a bottleneck in high-volume production environments. The cycle time must be factored into the overall manufacturing workflow.

Making the Right Choice for Your Goal

Selecting the appropriate annealing process depends on your specific technical and commercial requirements.

- If your primary focus is cost-effective stress relief and improved machinability where surface finish is not critical: A standard atmosphere annealing furnace is a practical and effective solution.

- If your primary focus is achieving a pristine, oxidation-free surface for a finished part: A vacuum annealing furnace is the superior choice, as it eliminates the need for secondary cleaning.

- If your primary focus is preparing a material with maximum uniformity for a critical subsequent process: The precise control and repeatability of a modern PLC-driven furnace are essential.

By understanding these core principles, you can effectively leverage annealing to improve your material quality, streamline your manufacturing process, and produce a more reliable final product.

Summary Table:

| Advantage | Description |

|---|---|

| Stress Relief | Eliminates internal stresses from manufacturing to prevent deformation and cracking. |

| Improved Machinability | Softens materials for easier cutting, reducing tool wear and costs. |

| Grain Refinement | Enhances mechanical properties by creating a uniform, robust microstructure. |

| Surface Integrity | Vacuum annealing prevents oxidation and decarburization for pristine finishes. |

| Process Control | PLC systems ensure precise, repeatable heating and cooling cycles. |

Ready to optimize your material processing with advanced annealing solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced efficiency and reliability. Contact us today to discuss how our tailored furnace solutions can benefit your specific applications!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- What are the primary inert gases used in vacuum furnaces? Optimize Your Heat Treatment Process