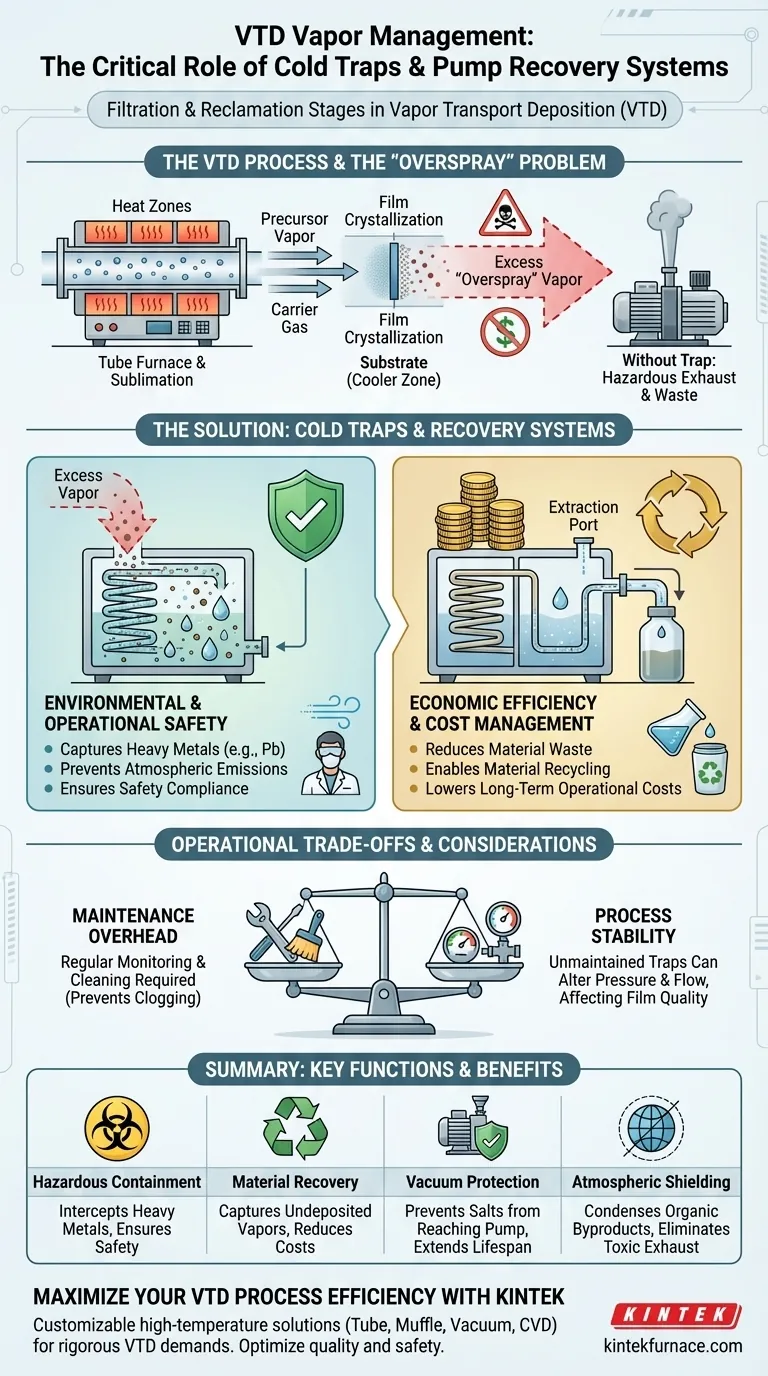

Cold traps and pump recovery systems serve as critical filtration and reclamation stages within Vapor Transport Deposition (VTD) setups. Their primary function is to capture excess precursor vapors—such as heavy metals and volatile organic salts—that fail to deposit on the substrate during the coating process. By intercepting these byproducts before they exit the system, these components prevent hazardous exhaust from reaching the atmosphere.

In the context of VTD, these systems act as both an environmental safeguard and a cost-saving mechanism, trapping toxic emissions to ensure safety compliance while allowing for the recycling of expensive raw materials.

The Role of Vapor Management in VTD

To understand the necessity of cold traps, one must first look at the VTD process itself.

The Source of Excess Vapor

A VTD system utilizes a tube furnace to create a controlled, multi-zone heating environment.

In the high-temperature zones, precursor materials undergo sublimation to generate vapor.

A carrier gas then transports these vapors to a substrate located in a cooler zone for condensation and film crystallization.

The "Overspray" Problem

However, not all vapor generated by the furnace successfully deposits onto the substrate.

Without a capture system, these residual vapors flow directly toward the vacuum pump and the exhaust vent.

This "overspray" creates the two distinct problems that cold traps are designed to solve: safety risks and material waste.

Ensuring Environmental and Operational Safety

The most immediate function of a cold trap or recovery system is hazardous waste containment.

Capturing Heavy Metals

VTD precursors often include hazardous materials, such as lead (Pb) or other heavy metals.

If these vapors pass through the pump and into the open air, they pose significant health risks to laboratory personnel and the surrounding environment.

Preventing Atmospheric Emissions

Volatile organic salts and other byproducts must also be contained.

Cold traps condense these vapors back into solids or liquids before they can exit the vacuum exhaust.

This ensures the system remains compliant with strict environmental safety standards regarding toxic emissions.

Economic Efficiency and Cost Management

Beyond safety, these systems provide a tangible economic advantage to the VTD process.

Reducing Material Waste

Precursor materials used in high-quality deposition are often rare and expensive.

A significant portion of this material does not end up on the final product during a standard run.

Enabling Material Recycling

Recovery systems allow you to reclaim the undeposited material accumulated in the trap.

By recycling these expensive raw materials, you can significantly reduce long-term operational costs.

Understanding the Operational Trade-offs

While essential, introducing cold traps and recovery systems adds complexity to the VTD setup.

Maintenance Overhead

Traps work by accumulating solid waste, which means they physically fill up over time.

They require regular monitoring and cleaning to prevent clogging, which can otherwise disrupt the vacuum flow or reduce pumping speed.

Process Stability

If a trap is not maintained, the accumulation of material can alter the pressure dynamics within the tube furnace.

This can unintentionally affect the spatial temperature gradient and carrier gas flow, potentially degrading the quality of the film crystallization.

Making the Right Choice for Your Goal

Selecting and maintaining the right recovery system depends on your specific operational priorities.

- If your primary focus is Environmental Compliance: Prioritize high-efficiency cold traps with redundant filtration to ensure zero emission of heavy metals like lead.

- If your primary focus is Cost Reduction: Select a recovery system design that allows for easy physical access and efficient extraction of condensed materials for recycling.

Effective vapor management is the bridge between a functional experiment and a sustainable, scalable manufacturing process.

Summary Table:

| Feature | Primary Function | Key Benefit |

|---|---|---|

| Hazardous Containment | Intercepts heavy metals like Lead (Pb) | Ensures environmental safety compliance |

| Material Recovery | Captures undeposited precursor vapors | Reduces operational costs via recycling |

| Vacuum Protection | Prevents volatile salts from reaching pump | Extends equipment lifespan and performance |

| Atmospheric Shielding | Condenses volatile organic byproducts | Eliminates toxic exhaust emissions |

Maximize Your VTD Process Efficiency with KINTEK

Don't let expensive precursor materials go to waste or compromise your lab's safety. KINTEK provides industry-leading high-temperature solutions—including Tube, Muffle, Vacuum, and CVD systems—specifically engineered to handle the rigorous demands of Vapor Transport Deposition.

Backed by our expert R&D and precision manufacturing, our systems are fully customizable to integrate advanced recovery stages tailored to your unique research needs.

Ready to optimize your deposition quality and safety standards?

Visual Guide

References

- Dachang Liu. Vapor Transport Deposition Technology for Perovskite Films. DOI: 10.1002/admi.202500064

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What are the advantages of the re-coating process? Boost Adsorbent Capacity Beyond Original Performance

- How does a resistance heating furnace contribute to Al/Cu bimetallic interface preparation? Expert Thermal Solutions

- Why is thermal growth oxidation preferred for SiO2 gate dielectrics? Superior Quality for a-IGZO TFTs

- What is the role of temperature control in MCM-41 synthesis? Master Precision Pore Engineering

- How does the analysis of optimized process paths assist in lab equipment selection? Expert Guide for Research Success

- Why is a high-temperature furnace with gas flow control necessary for Li6MnO4 precursors? Achieve Precise Synthesis

- What is the purpose of conducting high-temperature tensile testing on TC4 titanium alloy? Master Thermal Forming Limits

- What are the characteristics of a Batch Reactor for plastic pyrolysis? A Guide to Versatile Waste Processing