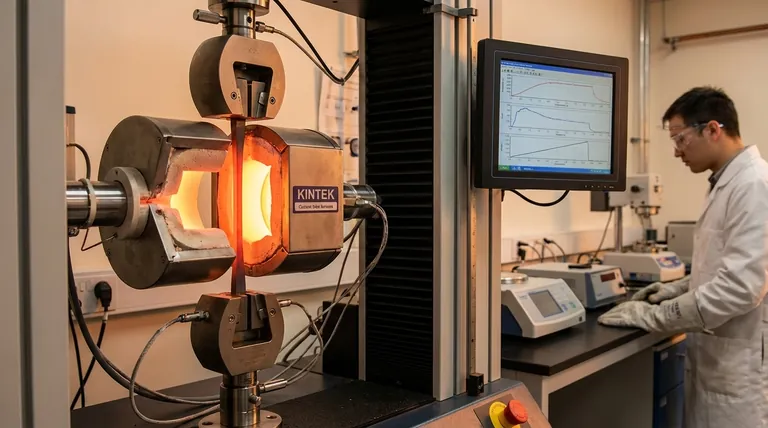

High-temperature tensile testing serves as the foundational diagnostic tool for characterizing how TC4 titanium alloy behaves under thermal stress. By simulating manufacturing conditions using an electronic universal testing machine equipped with a specific high-temperature furnace, engineers capture essential mechanical data—specifically yield strength, tensile strength, and elongation—across a spectrum of temperatures and strain rates.

This testing process transforms raw mechanical data into actionable manufacturing intelligence. It provides the physical evidence necessary to build accurate mathematical models, optimize forming temperatures like 750°C, and mitigate costly production defects such as cracking and springback.

Deriving Critical Mechanical Parameters

Measuring Strength and Ductility

The primary function of this test is to quantify how the material's strength degrades and ductility increases as heat is applied. The machine records the precise points of yield strength and tensile strength under thermal load.

Capturing Elongation Data

Beyond strength, the test measures elongation, which indicates how much the material can stretch before failure. This metric is vital for understanding the material's limits during complex shaping operations.

The Role of Strain Rates

The testing setup allows engineers to vary the speed at which the material is pulled, known as the strain rate. Capturing data at different rates helps predict how the alloy will react to faster or slower manufacturing speeds.

Optimizing Manufacturing Processes

Establishing Viscoplastic Models

The data collected provides the physical basis for creating viscoplastic constitutive models. These are complex mathematical frameworks that predict how the material flows and deforms over time under heat and stress.

Identifying the Optimal Thermal Window

Testing identifies the specific temperature ranges where the material offers the best balance of formability and strength. For TC4 titanium alloy, this data often points to 750°C as an optimal hot forming temperature.

Predicting and Preventing Defects

Mitigating Springback Risks

"Springback" occurs when a material tries to return to its original shape after forming, leading to dimensional inaccuracies. High-temperature testing data allows engineers to predict the magnitude of this effect and compensate for it in the tooling design.

Avoiding Material Failure

By understanding the elongation limits at specific temperatures, manufacturers can foresee risks of cracking. If the forming process exceeds the limits found during testing, the component will likely fail.

Understanding the Trade-offs

Simulation vs. Production Reality

While this testing provides a baseline, it is performed on standardized coupons, not complex geometries. Standardized testing cannot perfectly replicate the multi-axial stresses found in actual component manufacturing.

Equipment Sensitivity

The accuracy of the data is heavily dependent on the stability of the high-temperature furnace. Even minor fluctuations in temperature maintenance can skew the yield strength data, potentially leading to inaccurate constitutive models.

How to Apply This to Your Project

To maximize the utility of high-temperature tensile testing for TC4 titanium, align your analysis with your specific engineering objectives.

- If your primary focus is computational modeling: Prioritize data collection across a wide range of strain rates to ensure your viscoplastic constitutive models are robust and accurate.

- If your primary focus is process optimization: Concentrate on the elongation data to validate the specific hot forming temperature (e.g., 750°C) that minimizes the risk of cracking.

Accurate testing serves as the bridge between raw material potential and a flawless final component.

Summary Table:

| Parameter | Purpose in TC4 Testing | Impact on Manufacturing |

|---|---|---|

| Yield/Tensile Strength | Measures strength degradation under heat | Determines required forming force |

| Elongation | Quantifies material ductility/stretch | Predicts & prevents cracking during shaping |

| Strain Rate | Tests reaction to deformation speeds | Optimizes production cycle times |

| Viscoplastic Modeling | Creates mathematical flow frameworks | Enables accurate digital process simulation |

| Thermal Windows | Identifies optimal heat (e.g., 750°C) | Minimizes springback and dimensional errors |

Elevate Your Materials Testing with KINTEK Precision

Don't let inaccurate thermal data compromise your TC4 manufacturing. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as customizable high-temp lab furnaces designed specifically for high-precision tensile testing.

Whether you are building complex viscoplastic models or optimizing hot forming temperatures to eliminate cracking, our equipment provides the thermal stability your research demands.

Ready to achieve flawless component forming? Contact our engineering team today to find the perfect customizable high-temperature solution for your lab's unique needs.

References

- Tao Zhang, Xiaochuan Liu. Deformation Control of TC4 Titanium Alloy in Thin-Walled Hyperbolic Structures During Hot Forming Processes. DOI: 10.3390/ma17246146

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is calcination essential for NaFePO4 phase formation? Engineering High-Performance Sodium Iron Phosphate

- Why is high temperature control stability required for KAS method kinetics? Ensure Accurate Activation Energy Results

- How does the introduction of SiO2 as an additive improve the sintering process of solid electrolytes? Boost Densification

- What is the function of zone melting purification equipment in the preparation of CsPbBr3 perovskite single crystals? Key for 6N.

- What is the mechanism of using TeCl4 as a gaseous transport agent? Grow High-Integrity Single Crystals with Ease

- What core parameters does a sessile drop furnace provide for quartz glass? Master High-Temp Material Evaluation

- How do magnesium impurities influence lithium extraction? Accelerate Production with Heterogeneous Nucleation

- How does a high-precision PID temperature controller ensure the quality of biochar? Master Teff Husk Pyrolysis