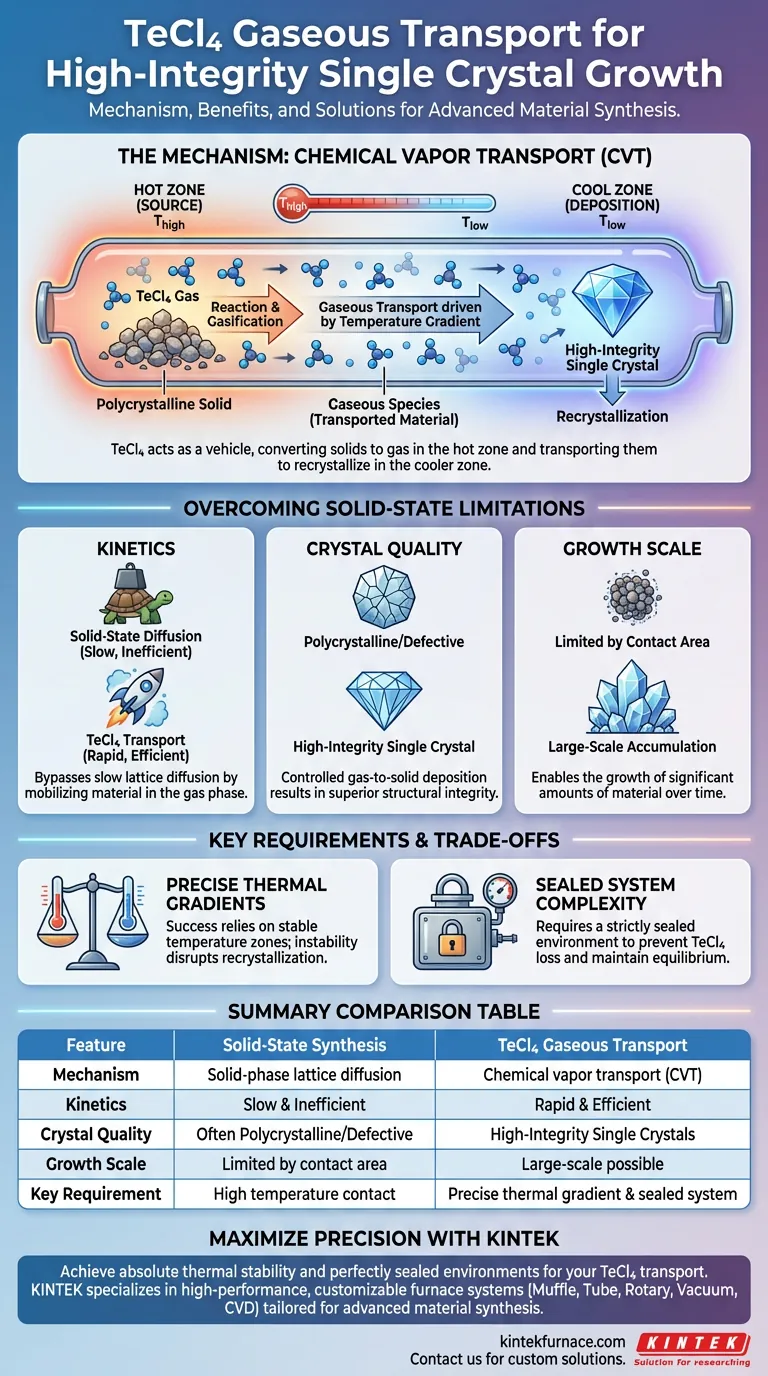

TeCl4 functions as a chemical transport medium that converts solid materials into gaseous species within a sealed furnace environment. This mechanism enables the movement of chemical components from a high-temperature source zone to a lower-temperature deposition zone. By facilitating this phase change, it effectively bypasses the inherent sluggishness of solid-state diffusion to grow high-integrity crystals.

While standard synthesis relies on slow direct contact between solids, TeCl4 acts as a vehicle to vaporize and transport material. This process is the key to producing large-scale single crystals with structural integrity that solid-state methods generally fail to achieve.

The Physics of the Transport Process

The Role of the Sealed Environment

The process begins in a sealed furnace environment. This closed system is critical to prevent the loss of the volatile transport agent and to maintain the chemical equilibrium necessary for transport.

Inside this system, TeCl4 interacts with the solid polycrystalline source material.

Reaction at High Temperatures

At the furnace's hotter zone, TeCl4 reacts with the polycrystalline solids.

This reaction converts the solid material into gaseous species. This phase conversion is the engine of the entire process, mobilizing the material for transport.

Recrystallization in the Cooler Zone

Once gasified, the chemical components travel to a lower-temperature zone within the furnace.

Driven by the temperature difference, the thermodynamic equilibrium shifts. This causes the gaseous species to release the transported material, which then recrystallizes as a single crystal.

Overcoming Solid-State Limitations

Bypassing Slow Diffusion

Standard solid-state synthesis relies on solid-phase diffusion, which is kinetically slow and often inefficient.

Atoms move with difficulty through solid lattices. By converting the material to a gas, TeCl4 removes this bottleneck, allowing for rapid and efficient movement of components.

Achieving High Integrity

The controlled nature of the gas-to-solid deposition results in superior crystal quality.

Because the material builds up gradually from the gas phase, the resulting crystals possess high integrity. This method is specifically used when standard methods fail to produce crystals of sufficient quality.

Enabling Large-Scale Growth

The efficiency of gaseous transport allows for the accumulation of significant amounts of material over time.

This makes TeCl4 transport essential for producing large-scale single crystals, a feat that is often impossible using traditional solid-state mixing techniques.

Understanding the Trade-offs

Dependence on Temperature Gradients

The success of this method relies entirely on the precise management of temperature zones.

Since the transport moves from a high-temperature zone to a lower-temperature zone, any instability in this thermal gradient can disrupt the recrystallization process or stop transport altogether.

Complexity of Sealed Systems

Unlike open-air solid-state firing, this method requires a strictly sealed environment.

This adds a layer of technical complexity to the furnace setup, as leaks or seal failures will compromise the transport medium (TeCl4) and halt crystal growth.

Making the Right Choice for Your Goal

This method is a specific tool for overcoming kinetic barriers in crystal growth.

- If your primary focus is crystal size: Utilize TeCl4 transport to bypass the volume limitations inherent in solid-state diffusion, enabling large-scale growth.

- If your primary focus is structural quality: rely on the gas-phase recrystallization process to produce high-integrity single crystals that are free from the defects common in polycrystalline solids.

By leveraging the phase-changing properties of TeCl4, you transform a slow physical struggle into an efficient chemical transport system.

Summary Table:

| Feature | Solid-State Synthesis | TeCl4 Gaseous Transport |

|---|---|---|

| Mechanism | Solid-phase lattice diffusion | Chemical vapor transport (CVT) |

| Kinetics | Slow and inefficient | Rapid and efficient |

| Crystal Quality | Often polycrystalline/defective | High-integrity single crystals |

| Growth Scale | Limited by contact area | Large-scale accumulation possible |

| Key Requirement | High temperature contact | Precise thermal gradient & sealed system |

Maximize Your Crystal Growth Precision with KINTEK

Achieving high-integrity single crystals through TeCl4 gaseous transport requires absolute thermal stability and a perfectly sealed environment. At KINTEK, we specialize in providing high-performance furnace systems tailored for advanced material synthesis.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the unique temperature gradients and chemical requirements of your research.

Ready to elevate your lab's high-temperature capabilities? Contact us today to discuss your custom furnace solution with our technical experts.

Visual Guide

References

- Matthias Weil, Harishchandra Singh. CoTeO<sub>4</sub> – a wide-bandgap material adopting the dirutile structure type. DOI: 10.1039/d3ma01106b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Heat Treat Sintering and Brazing Furnace

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What is the role of a customized drying station with nitrogen purging? Optimize Polymer Blend Membrane Processing

- What role do constant temperature water baths or ovens play in the sol-gel process for carbon aerogels? Master Kinetics

- Why Use a Vacuum Oven for Cu-Cu2O/g-C3N4 Catalysts? Preserve Purity and Structural Integrity

- How does a high-temperature laboratory furnace contribute to the formation of high-quality CsV3Sb5 single crystals?

- Why is vacuum distillation preferred for biodiesel ethanol removal? Protect Fuel Quality with Low-Temp Processing

- What are the equipment requirements for high-temperature furnaces during magnetic biochar synthesis? Find the key specs.

- How do continuous furnaces differ from batch furnaces? Choose the Right Furnace for Your Production Needs

- How does a high-temperature annealing furnace regulate cold-rolled steel? Optimize Manganese Steel Performance