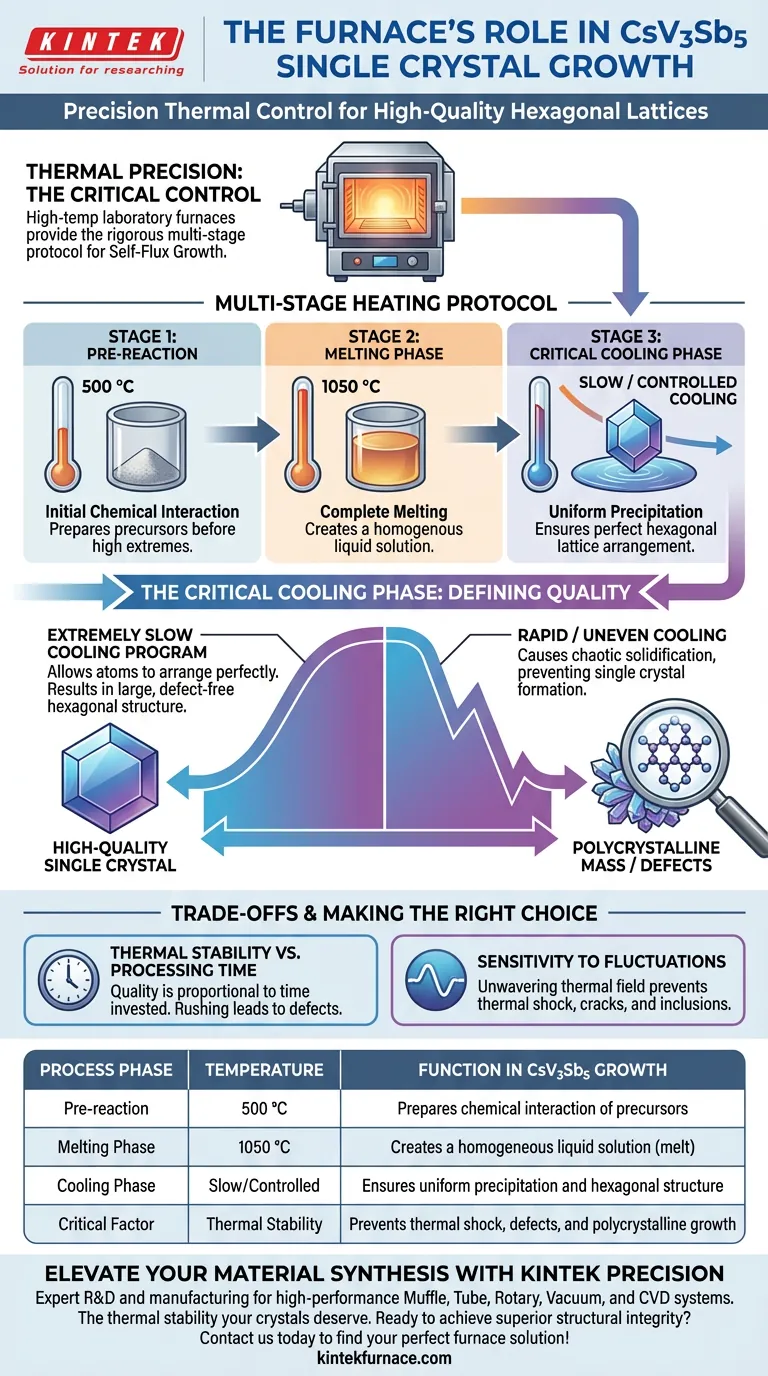

A high-temperature laboratory furnace contributes to CsV3Sb5 formation by providing the precise thermal environment necessary for the self-flux growth method. Specifically, it enables a rigorous multi-stage heating protocol—including a pre-reaction at 500 °C and a melting phase at 1050 °C—followed by a controlled, slow cooling process. This thermal precision allows for the uniform precipitation of components from a saturated melt, resulting in large, high-quality hexagonal single crystals.

The furnace acts as the critical control mechanism for the self-flux method, bridging the gap between raw precursors and a structured lattice. Its primary function is to execute complex temperature profiles that drive the transition from a liquid melt to a solid, defect-free crystal.

The Role of Thermal Precision in Self-Flux Growth

To understand how the furnace creates high-quality CsV3Sb5, one must look beyond simple heating. The furnace creates a specific thermal field that dictates the chemical kinetics of the growth process.

Enabling Multi-Stage Protocols

The formation of CsV3Sb5 is not a single-step event. The furnace must support programmable heating profiles to manage distinct phases of chemical interaction.

The Pre-Reaction Phase

Initially, the furnace holds the temperature at 500 °C. This pre-reaction step prepares the materials, ensuring the components begin to interact chemically before the system is pushed to higher extremes.

The Melting Phase

Following the pre-reaction, the furnace ramps the temperature up to 1050 °C. This high heat ensures the complete melting of the mixture, creating a homogenous liquid solution essential for the subsequent growth phase.

The Critical Cooling Phase

While heating prepares the material, the quality of the final crystal is determined by how the furnace handles the cooling process.

Controlled Precipitation

The furnace executes an extremely slow cooling program. This is the most critical contribution of the equipment.

Preventing Supersaturation Shocks

By lowering the temperature gradually, the furnace allows the CsV3Sb5 to precipitate uniformly from the saturated melt. If cooling were rapid or uneven, the material would solidify chaotically, resulting in small, polycrystalline masses rather than a single crystal.

Achieving Hexagonal Structure

The stability provided by the furnace during this slow cooling allows the atoms to arrange themselves perfectly into the desired hexagonal lattice structure. This controlled environment is what differentiates a high-quality single crystal from a defective sample.

Understanding the Trade-offs

While high-temperature furnaces are essential tools, relying on them for self-flux growth involves specific challenges that must be managed.

Thermal Stability vs. Processing Time

The requirement for "extremely slow cooling" means the equipment is occupied for long durations. Rushing this process to free up equipment is the most common cause of crystal defects. Quality is directly proportional to the time invested in the cooling gradient.

Sensitivity to Fluctuations

The furnace must maintain an unwavering thermal field. Any unintentional temperature spikes or drops during the cooling phase can introduce thermal shock, leading to cracks or inclusions within the crystal. This mirrors the challenges seen in other methods (like the slip system activation in Barium Titanate), where precise control is the only defense against structural failure.

Making the Right Choice for Your Goal

To maximize the quality of your CsV3Sb5 crystals, align your furnace operations with your specific research objectives.

- If your primary focus is Crystal Size: Prioritize the duration of the cooling phase; the slower and more stable the temperature descent, the larger the single crystal can grow.

- If your primary focus is Structural Integrity: Ensure your furnace is calibrated to prevent thermal fluctuations during the transition from 1050 °C, as stability prevents cracking and defects.

Ultimately, the furnace is not merely a heat source, but a precision instrument that dictates the structural destiny of your material.

Summary Table:

| Process Phase | Temperature | Function in CsV3Sb5 Growth |

|---|---|---|

| Pre-reaction | 500 °C | Prepares chemical interaction of precursors |

| Melting Phase | 1050 °C | Creates a homogeneous liquid solution (melt) |

| Cooling Phase | Slow/Controlled | Ensures uniform precipitation and hexagonal structure |

| Critical Factor | Thermal Stability | Prevents thermal shock, defects, and polycrystalline growth |

Elevate Your Material Synthesis with KINTEK Precision

Precision is the difference between a defective sample and a high-quality hexagonal lattice. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle the rigorous multi-stage heating and extremely slow cooling protocols required for CsV3Sb5 and other advanced materials.

Whether you need standard lab high-temp furnaces or a system fully customizable for your unique research needs, KINTEK provides the thermal stability your crystals deserve.

Ready to achieve superior structural integrity? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Yongqing Cai, Kai Chen. Emergence of quantum confinement in topological kagome superconductor CsV3Sb5. DOI: 10.1038/s43246-024-00461-z

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the function of a drying oven during the chemical activation of biochar? Optimize Your Porous Carbon Structure

- Why must T91 steel ingots undergo long-term homogenization? Ensure High-Performance Microstructural Uniformity

- Why is the initial concentration of siloxane systems performed in a vacuum oven? Achieve Defect-Free Material Curing

- How does a rotary evaporator contribute to the concentration phase of TiO2 and ZrO2 pastes? Achieve Precision Viscosity

- What is the purpose of using a laboratory drying oven for catalyst recycling? Optimize Performance & Data Integrity

- What is the purpose of setting an industrial drying oven to 70°C for sludge? Preserve Volatiles & Optimize Pre-treatment

- What is the use of dental ceramic? Achieve Lifelike, Durable, and Biocompatible Restorations

- What mechanism causes the formation of micro-cracks in zinc clinker during microwave heating? Boost Leaching Efficiency