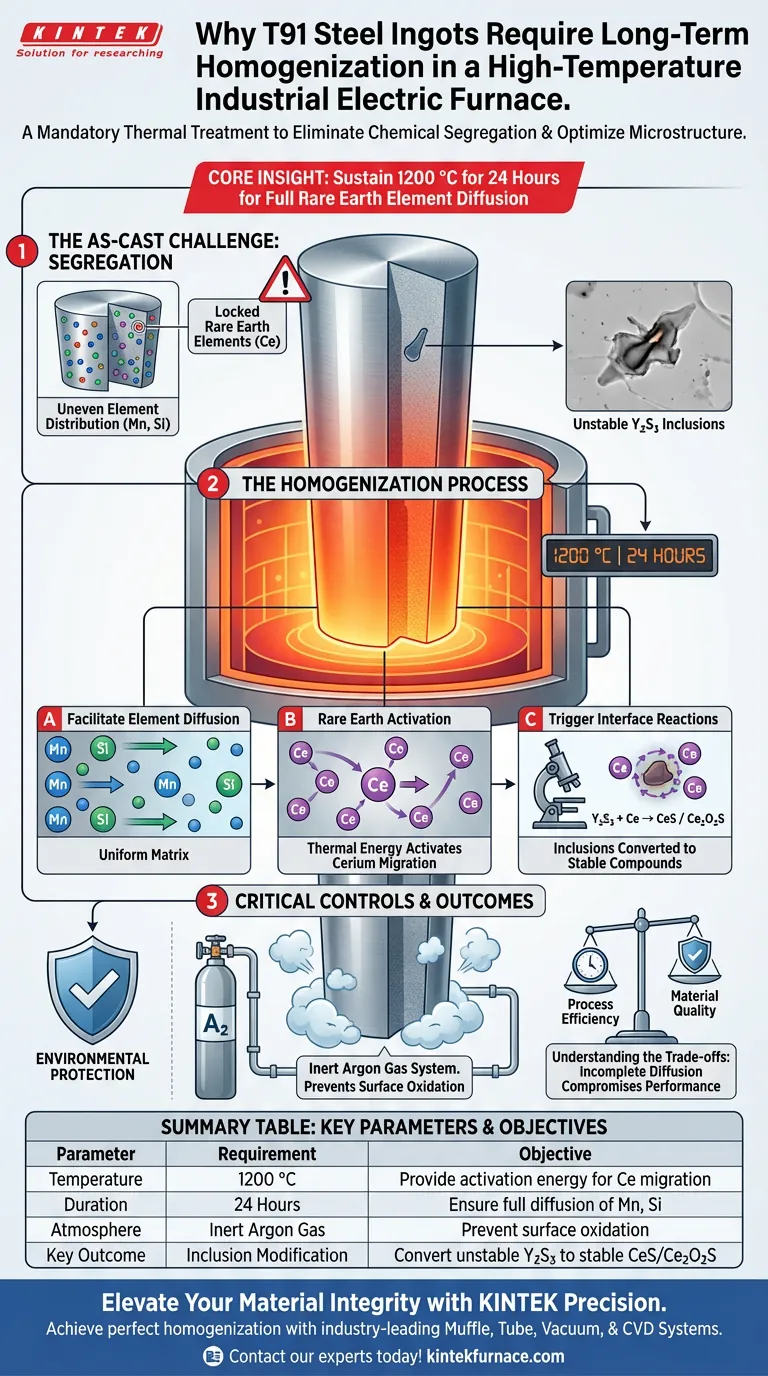

Homogenization is a mandatory thermal treatment designed to eliminate chemical segregation inherent in the as-cast structure of T91 steel. By sustaining the ingot at 1200 °C for 24 hours in an industrial electric furnace, the process drives the full diffusion of rare earth elements—specifically Cerium (Ce)—to modify and stabilize the steel’s internal inclusions.

Core Insight: The primary goal of this long-term heat treatment is to trigger specific solid-state interface reactions. It utilizes thermal energy to migrate Cerium atoms, converting unstable inclusions into stable compounds like CeS or Ce2O2S to ensure uniform material properties.

The Mechanics of Microstructural Stabilization

Eliminating As-Cast Segregation

When steel ingots are cast, chemical elements often distribute unevenly, leading to "segregation."

Homogenization corrects this by keeping the steel at high temperatures for an extended period.

This allows substitutional solute elements, such as Manganese (Mn) and Silicon (Si), to diffuse from areas of high concentration to low concentration, resulting in a uniform matrix.

Facilitating Rare Earth Diffusion

For T91 steel specifically, the treatment focuses on the behavior of rare earth elements.

The protocol of 1200 °C for 24 hours provides the activation energy required for Cerium (Ce) atoms to migrate effectively through the lattice.

Without this sustained duration and heat, the rare earth elements would remain locked in their segregated, as-cast positions.

Triggering Interface Reactions

The most critical outcome of this diffusion is the modification of inclusions.

As Cerium migrates to inclusion interfaces, it triggers a chemical transformation.

Existing compounds, such as Y2S3, are converted into CeS or Ce2O2S. This ensures that the rare earth inclusions are stable in both morphology and composition.

Critical Process Controls

Environmental Protection

Maintaining steel at these temperatures poses a risk to the surface integrity of the ingot.

To prevent excessive surface oxidation, the furnace must be equipped with an inert gas protection system, typically using argon.

This creates a barrier between the steel and oxygen, preserving the material while the internal diffusion occurs.

Understanding the Trade-offs

Process Efficiency vs. Material Quality

The 24-hour cycle at 1200 °C represents a significant commitment of time and energy.

Shortening this cycle to save costs will result in incomplete diffusion, leaving behind segregated elements and unstable inclusions that compromise the steel's performance.

Temperature Precision Risks

The window for effective homogenization is specific.

If temperatures drop below the target, diffusion rates slow drastically; if they rise too high without protection, the ingot risks melting or severe surface degradation.

Making the Right Choice for Your Goal

To optimize the quality of T91 steel ingots, you must balance the thermal requirements with environmental controls.

- If your primary focus is internal structural integrity: Strictly adhere to the 24-hour duration at 1200 °C to guarantee the complete transformation of Y2S3 inclusions into stable Ce-based compounds.

- If your primary focus is surface yield: Ensure your furnace utilizes a robust argon inert gas system to mitigate the oxidation risks inherent in long-term high-temperature exposure.

Uniformity in T91 steel is not an accident of casting, but the result of precise, energy-intensive diffusion.

Summary Table:

| Process Parameter | Requirement | Objective |

|---|---|---|

| Temperature | 1200 °C | Provide activation energy for Ce atom migration |

| Duration | 24 Hours | Ensure full diffusion of solute elements (Mn, Si) |

| Atmosphere | Inert Argon Gas | Prevent surface oxidation and material loss |

| Key Outcome | Inclusion Modification | Convert unstable Y2S3 into stable CeS/Ce2O2S |

Elevate Your Material Integrity with KINTEK Precision

Achieving the perfect homogenization of T91 steel requires rigorous thermal control and specialized environments. KINTEK provides industry-leading Muffle, Tube, and Vacuum systems, including advanced CVD systems designed for inert gas protection and precise long-term heating.

Whether you need customizable high-temp furnaces for R&D or large-scale manufacturing, our expert-backed solutions ensure your alloys meet the highest standards of structural uniformity.

Ready to optimize your heat treatment process? Contact our technical experts today to find the ideal furnace for your unique needs!

Visual Guide

References

- Jun Liu, Xikou He. Effect of Ce-Y Composite Addition on the Inclusion Evolution in T91 Heat-Resistant Steel. DOI: 10.3390/ma18071459

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why must (MnFeNiCo)3O4 materials undergo a secondary calcination? Key Steps to Optimizing FCC Spinel Structure

- What are the critical functions of cold recycled gas nozzles? Optimize Oil Shale Retorting and Energy Recovery

- How does extending the duration of high-temperature constant phase affect iron grain growth? Maximize Zinc Extraction

- What is the role of high-precision furnaces in Inconel 718 heat treatment? Master Microstructural Engineering

- What are the advantages of using a microwave reaction system? Rapid & Uniform Synthesis of Doped Hydroxyapatite

- Why must calcination equipment be used to pre-treat ZSM-5 zeolite? Ensure Accurate VOC Adsorption Testing

- Why is an industrial forced air drying oven required for drying banana slices? Unlock Precision & Nutritional Quality

- What are the advantages of using multi-stage laboratory sintering furnaces? Ensure Defect-Free Powder Metallurgy