Multi-stage laboratory sintering furnaces provide a critical advantage in powder metallurgy by separating the heating process into distinct, controlled phases to ensure structural integrity. By decoupling the removal of additives from the final hardening process, these furnaces prevent the internal defects that commonly occur when volatile materials are trapped inside a densifying product.

The core benefit of this two-stage approach is the elimination of internal cracking. By dedicating a specific thermal plateau to lubricant removal, you ensure the material is free of volatile contaminants before it reaches the high temperatures required for final sintering.

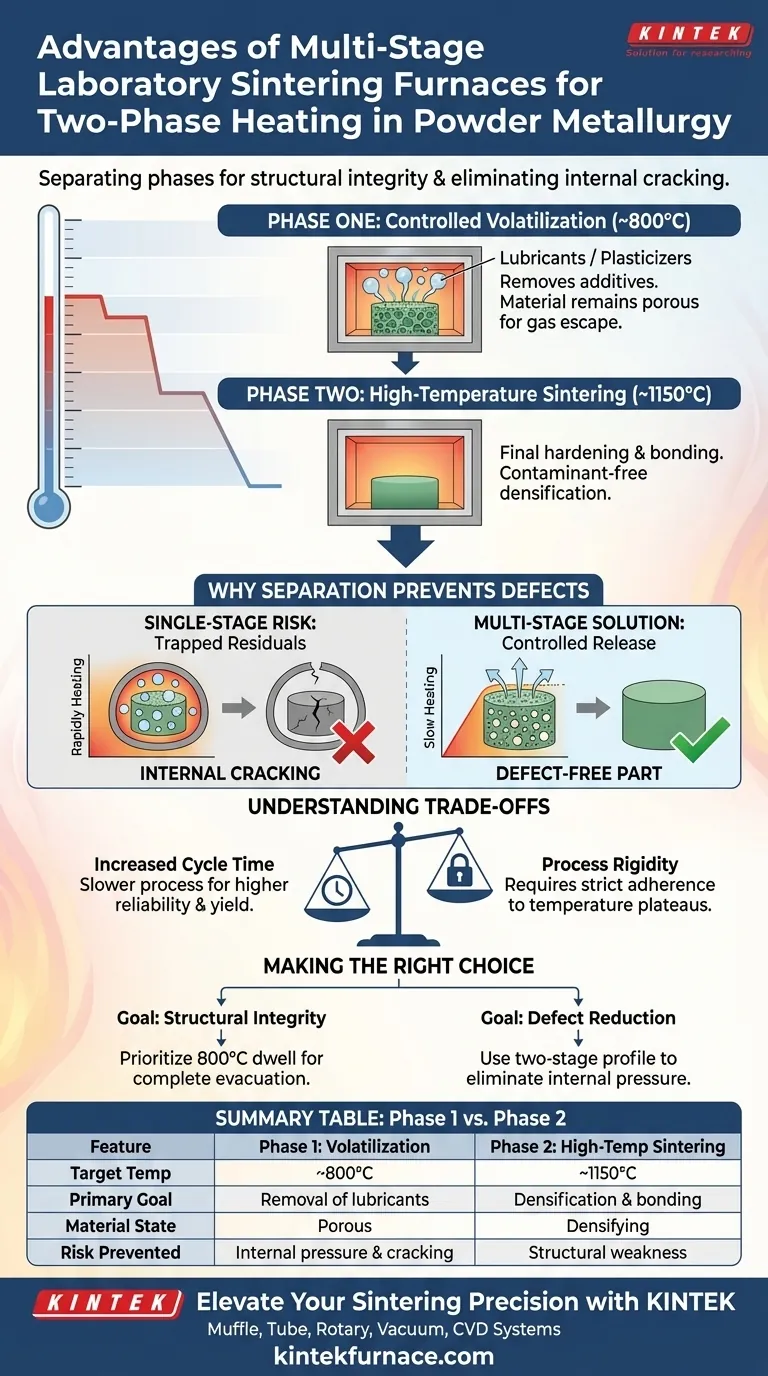

The Mechanics of Two-Phase Heating

To understand the advantage, you must look at how the furnace manages temperature profiles. The multi-stage approach abandons a linear heating ramp in favor of a stepped process.

Phase One: Controlled Volatilization

The first stage targets a temperature of approximately 800°C.

At this specific thermal plateau, the furnace creates the ideal environment for the complete volatilization of lubricants or plasticizers. These are additives originally introduced to assist during the pressing of the powder.

Phase Two: High-Temperature Sintering

Once the additives are removed, the furnace transitions to the second stage, reaching approximately 1150°C.

This serves as the actual sintering phase. Because the contaminants were removed in the previous step, the material can now densify and bond effectively without interference.

Why Separation Prevents Defects

The primary reason for adopting a multi-stage furnace is risk mitigation. Attempting to combine these processes often leads to product failure.

Avoiding Trapped Residuals

If the temperature rises too quickly to sintering levels (1150°C), the outer shell of the product may begin to densify while lubricants are still volatilizing inside.

This traps gases within the material. The multi-stage profile ensures that all residual lubricants are expelled while the structure is still porous enough to let gas escape.

Eliminating Internal Cracking

When volatile elements are trapped inside a sintering product, they create internal pressure.

This pressure frequently results in internal defects or cracking. By strictly separating the cleaning phase (800°C) from the hardening phase (1150°C), you effectively neutralize the root cause of these structural failures.

Understanding the Trade-offs

While multi-stage sintering offers superior quality control, it introduces specific operational considerations.

Increased Cycle Time

Implementing a distinct dwell time at 800°C inevitably extends the total duration of the sintering cycle.

You are trading processing speed for higher reliability. This approach is less about maximizing throughput and more about maximizing the yield of defect-free parts.

Process Rigidity

This method requires strict adherence to specific temperature plateaus.

Operators must ensure the first stage is sufficient to remove all lubricants before the second stage begins; otherwise, the benefits of the multi-stage architecture are lost.

Making the Right Choice for Your Goal

The decision to use a multi-stage profile depends on your specific quality requirements and the composition of your green parts.

- If your primary focus is Structural Integrity: Prioritize the 800°C dwell time to ensure every trace of lubricant is evacuated before the material begins to close up.

- If your primary focus is Defect Reduction: Use this two-stage profile to eliminate the internal pressure caused by trapped gases, which is the leading cause of sintering cracks.

Multi-stage heating transforms sintering from a gamble into a predictable, controlled sequence that guarantees a cleaner, stronger final product.

Summary Table:

| Feature | Phase 1: Volatilization | Phase 2: High-Temperature Sintering |

|---|---|---|

| Target Temp | ~800°C | ~1150°C |

| Primary Goal | Removal of lubricants/plasticizers | Material densification and bonding |

| Material State | Porous (allows gas escape) | Densifying (final hardening) |

| Risk Prevented | Internal pressure and cracking | Structural weakness from contaminants |

Elevate Your Sintering Precision with KINTEK

Don’t compromise on structural integrity. KINTEK’s advanced laboratory high-temp furnaces are engineered to handle complex multi-stage cycles with unmatched thermal accuracy. Backed by expert R&D and manufacturing, we provide customizable Muffle, Tube, Rotary, Vacuum, and CVD systems designed to eliminate internal defects and maximize your yield of high-quality parts.

Ready to optimize your powder metallurgy process? Contact KINTEK today to discuss your unique heating needs!

Visual Guide

References

- Petko Naydenov. DETERMING THE COMPENSATING ACTION OF COPPER AFTER SINTERING OF POWDER METALLURGICAL STRUCTURAL STEELS. DOI: 10.17770/etr2025vol4.8439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of activated carbon in tantalum processing? Enhance Your Carburization Efficiency Today

- Why must temperature loss be monitored during the aluminum alloy refining cycle? Essential Tips for Casting Success

- What is the significance of an in-situ high-temperature heating stage? Unlock Real-Time Crystal Structure Insights

- What is the significance of using a high-precision gas mass flow controller for hydrogen flow? | Master Uniform Thermal Reduction

- What is the purpose of using an industrial oven for the pretreatment of reinforcement powders? | Enhance Composite Bond

- How does heat treatment affect the TPU encapsulation layer? Optimize Flexible Sensor Durability & Bonding

- What is the importance of the feeding system and ore distributing device? Unlock Peak Oil Shale Retorting Efficiency

- What is the primary process objective of using an electric furnace in glass experiments? Analyze Stress & Heat Transfer