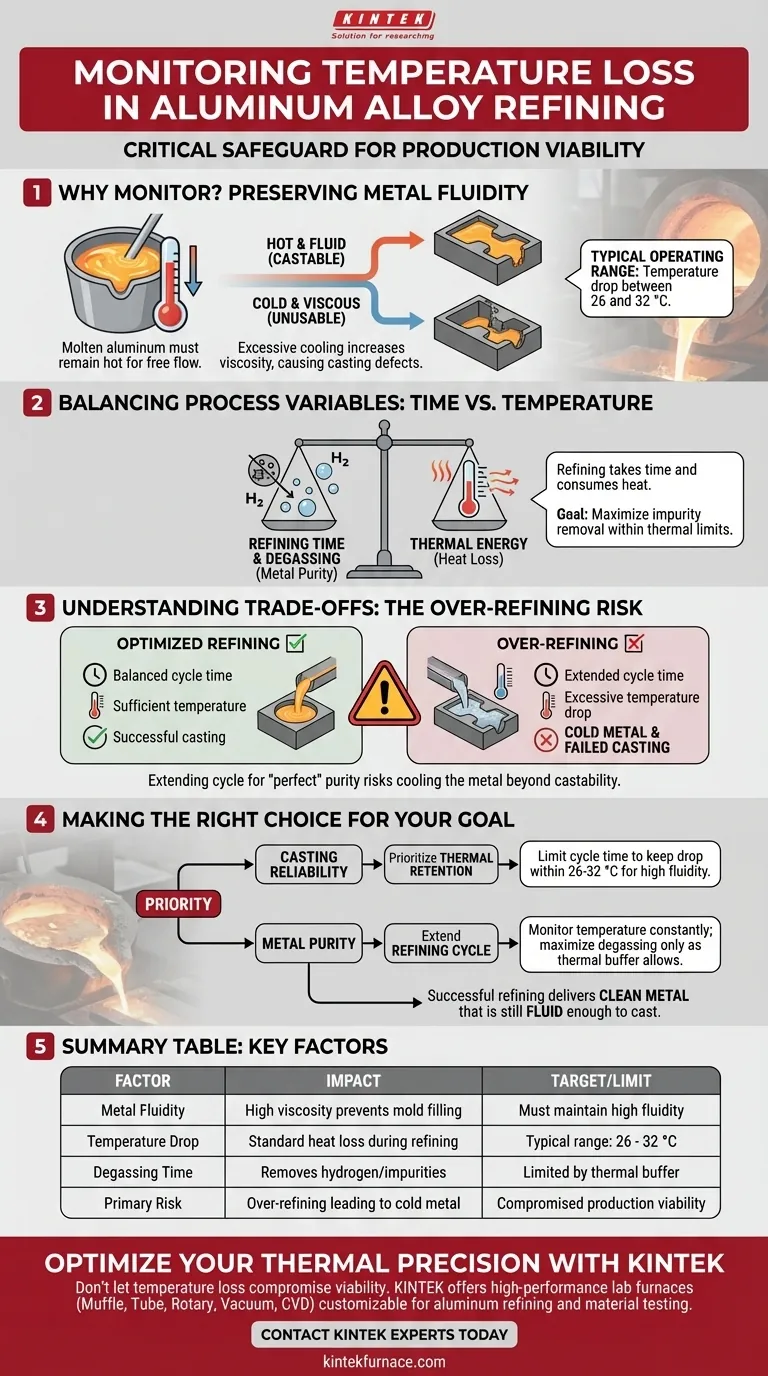

Temperature monitoring is the critical safeguard for production viability. In the aluminum alloy refining cycle, monitoring temperature loss is mandatory to ensure the molten metal retains sufficient fluidity for the final casting process. If the temperature drops too low, the metal cannot fill molds correctly, compromising the entire production run.

While refining is necessary to remove impurities, the process inherently consumes heat. You must monitor the temperature drop to ensure a balance between thorough degassing and retaining the thermal energy required for successful casting.

Preserving Metal Fluidity

The Link to Castability

The primary technical reason for monitoring temperature loss is fluidity. Molten aluminum must remain hot enough to flow freely into molds during the casting stage.

The Consequence of Heat Loss

If the refining cycle allows the metal to cool excessively, its viscosity increases. This lack of fluidity prevents the alloy from properly filling complex mold geometries, leading to defective castings.

Typical Operating Ranges

In standard refining operations, the temperature drop often falls between 26 and 32 °C. Monitoring this specific range helps operators predict the final condition of the melt before it reaches the casting station.

Balancing Process Variables

The Time vs. Temperature Equation

Refining takes time, and time equals heat loss. As you extend the refining cycle to improve metal purity, you inevitably lose thermal energy.

Managing Degassing Requirements

The goal of refining is often thorough degassing to remove hydrogen and impurities. However, this process cannot be indefinite; it is constrained by the thermal limits of the molten bath.

Strategic Retention

Operators must maintain a strict balance between achieving the necessary chemical quality (degassing) and thermal retention. The cycle must end while the metal is still hot enough to cast, even if slightly more refining were theoretically possible.

Understanding the Trade-offs

The Risk of Over-Refining

Extending the refining time to achieve "perfect" purity is a common pitfall. If the refining time is too long, the temperature loss will exceed the safe threshold, rendering the metal unusable for the intended casting process.

Operational Compromise

You often cannot maximize both variables simultaneously. You must accept a calculated temperature drop to achieve necessary quality, but you must strictly limit that drop to protect downstream production capability.

Making the Right Choice for Your Goal

To optimize your refining cycle, you must weigh the priority of metal cleanliness against the physical constraints of your casting equipment.

- If your primary focus is Casting Reliability: Prioritize thermal retention by limiting cycle time to keep the temperature drop within the 26-32 °C range, ensuring high fluidity.

- If your primary focus is Metal Purity: Extend the refining cycle for maximum degassing only as far as your thermal buffer allows, monitoring the temperature constantly to prevent freezing issues.

Successful aluminum refining is not just about cleaning the metal; it is about delivering clean metal that is still fluid enough to cast.

Summary Table:

| Factor | Impact on Aluminum Refining | Target/Limit |

|---|---|---|

| Metal Fluidity | High viscosity prevents mold filling | Must maintain high fluidity |

| Temperature Drop | Standard heat loss during refining | Typical range: 26 - 32 °C |

| Degassing Time | Removes hydrogen/impurities | Limited by thermal buffer |

| Primary Risk | Over-refining leading to cold metal | Compromised production viability |

Optimize Your Thermal Precision with KINTEK

Don't let temperature loss compromise your production viability. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of high-performance lab furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all of which are fully customizable to meet your unique aluminum refining and material testing needs.

Our advanced heating solutions ensure you maintain the perfect balance between metal purity and thermal retention. Contact KINTEK experts today to discover how our high-temperature systems can enhance your lab's efficiency and guarantee casting reliability.

Visual Guide

References

- Ladislav Socha, Petr Nuska. Assessment of refining efficiency during the refining cycle in a foundry degassing unit in industrial conditions. DOI: 10.1038/s41598-024-51914-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are some examples of medium-temperature industrial heating processes? Optimize Material Properties Efficiently

- What role does pack media play in the solid-state powder boriding process? Enhance Metal Hardness at High Temperatures

- What is the significance of using a laboratory vacuum drying oven during the catalyst recovery phase of depolymerization?

- What are the advantages of a high-pressure nitrogen environment? Speed and Efficiency in Wood Thermal Modification

- How does a high-precision temperature control system contribute to NMC synthesis? Precision in XRD In-Situ Experiments

- What is the function of a drying oven in the chemical activation of biochar with phosphoric acid? Optimize Biochar Quality

- What is the purpose of using a high-temperature universal material testing machine for Ti-6Al-4Zr-4Nb evaluation?

- What are the core process advantages of using a microwave reactor? Maximize Speed & Efficiency in Lab Characterization