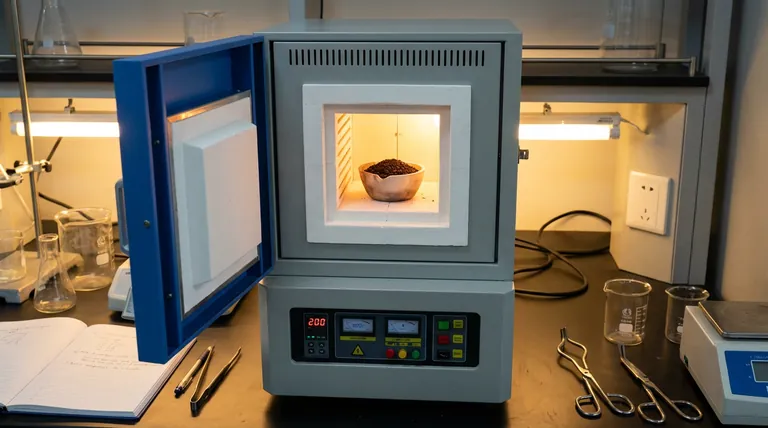

In the chemical activation of biochar using phosphoric acid, the drying oven serves as a critical chemical stabilization stage rather than a simple moisture removal tool. By maintaining a steady environment at approximately 200 °C, this unit initiates vital cross-linking between the acid and the biomass while preventing hazardous instabilities during later processing.

Core Takeaway While standard drying merely evaporates water, this specific pre-treatment integrates the phosphoric acid into the biomass structure chemically. This "curing" phase is essential to prevent structural collapse and violent reactions when the material is eventually subjected to high-temperature pyrolysis.

The Critical Functions of Thermal Pre-Treatment

Promoting Chemical Cross-Linking

The primary function of the oven at 200 °C is to drive a reaction between the impregnating agent and the feedstock. The heat facilitates chemical cross-linking between the orthophosphoric acid and the biomass's natural polymers, specifically cellulose and lignin.

This reaction effectively anchors the activating agent within the carbon matrix. Without this step, the acid might remain superficial, leading to poor activation and inferior pore development in the final biochar.

Preventing Structural Collapse

Rapid heating of wet biomass can generate internal steam pressure capable of destroying the material's integrity. By removing physically adsorbed water and free moisture at a controlled rate, the drying oven prevents the irregular collapse of the pore structure.

If moisture were left in the material during the high-temperature pyrolysis phase, the sudden expansion of steam would fracture the developing carbon skeleton, resulting in a mechanically weak product.

Mitigating Process Hazards

Safety is a major operational function of this pre-treatment step. The drying oven removes excess solvent to prevent violent splashing that can occur when wet, acid-soaked materials are introduced to extreme heat.

Ensuring the material is "cured" creates a stable precursor. This stability ensures that the subsequent carbonization is even and controlled, rather than chaotic and dangerous.

Understanding the Trade-offs

Temperature Sensitivity

Operating the oven at the recommended 200 °C is a precise balance. This temperature is significantly higher than standard laboratory drying (typically 60 °C to 100 °C), which is used simply to dry materials without altering surface chemistry.

At 200 °C, you are intentionally altering the chemistry. If the temperature is too low, the cross-linking between the acid and cellulose may be incomplete, reducing the quality of the biochar. Conversely, if the temperature is uncontrolled or excessively high, you risk premature combustion or the loss of volatile components intended for carbonization.

Making the Right Choice for Your Goal

To optimize your biochar production, align your oven settings with your specific processing stage:

- If your primary focus is Phosphoric Acid Activation: Adhere to the 200 °C standard to ensure proper cross-linking between the acid and the lignin/cellulose matrix.

- If your primary focus is General Drying (No Acid): Lower the temperature to 100–105 °C to remove physical moisture without triggering premature chemical changes.

- If your primary focus is Protecting Surface Groups: Consider lower temperatures (around 60 °C) or vacuum drying to prevent oxidation, though this applies more to finished catalysts than acid-impregnated precursors.

The drying oven is not just preparing the sample for the furnace; it is defining the foundational chemistry of your final carbon material.

Summary Table:

| Stage | Temperature | Primary Function | Chemical Effect |

|---|---|---|---|

| Acid Curing | ~200 °C | Chemical Stabilization | Initiates cross-linking between acid and biomass polymers |

| General Drying | 100–105 °C | Moisture Removal | Evaporates physically adsorbed water |

| Surface Protection | ~60 °C / Vacuum | Oxidation Prevention | Maintains integrity of sensitive surface functional groups |

| Pyrolysis Pre-treatment | Variable | Safety Mitigation | Prevents violent splashing and steam-induced pore collapse |

Maximize Your Biochar Performance with KINTEK

Precise thermal control is the difference between a collapsed structure and a high-performance carbon matrix. Backed by expert R&D and manufacturing, KINTEK offers advanced Muffle, Tube, and Vacuum systems designed to handle the rigorous demands of chemical activation and high-temperature pyrolysis.

Whether you are performing sensitive acid curing at 200°C or complex CVD processes, our customizable lab high-temp furnaces provide the uniformity and stability your research requires. Contact KINTEK today to discover how our tailored heating solutions can enhance your material science workflows and ensure superior product outcomes.

References

- Kinga Morlo, Ryszard Dobrowolski. Optimization of Pt(II) and Pt(IV) Adsorption from a Water Solution on Biochar Originating from Honeycomb Biomass. DOI: 10.3390/molecules29020547

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- What are the key considerations when choosing a continuous furnace? Optimize Your High-Volume Production

- What role does an RTA system play in Zirconia preparation? Master Phase Transformation for Advanced Deposition

- Why is SF6 gas utilized as the primary inhibitor in AS-ALD on ZrO2? Master Defect-Based Passivation Strategy

- How does a high-precision infrared temperature measurement system influence the sintering quality of Al2O3/TiC ceramics?

- What is the purpose of using a rotary evaporator or a vacuum drying oven? Preserving SiC Powder Quality Post-Milling

- What is the primary function of glass matrices in HLW vitrification? Achieve Safe Radioactive Waste Immobilization

- How does oxygen-enhanced alkaline thermal treatment benefit high-purity cellulose pulp? Achieve Superior Fiber Yield

- Why specific constant temperature holding times for NbC and Cr7C3? Achieve Stoichiometric Precision in Lab Synthesis