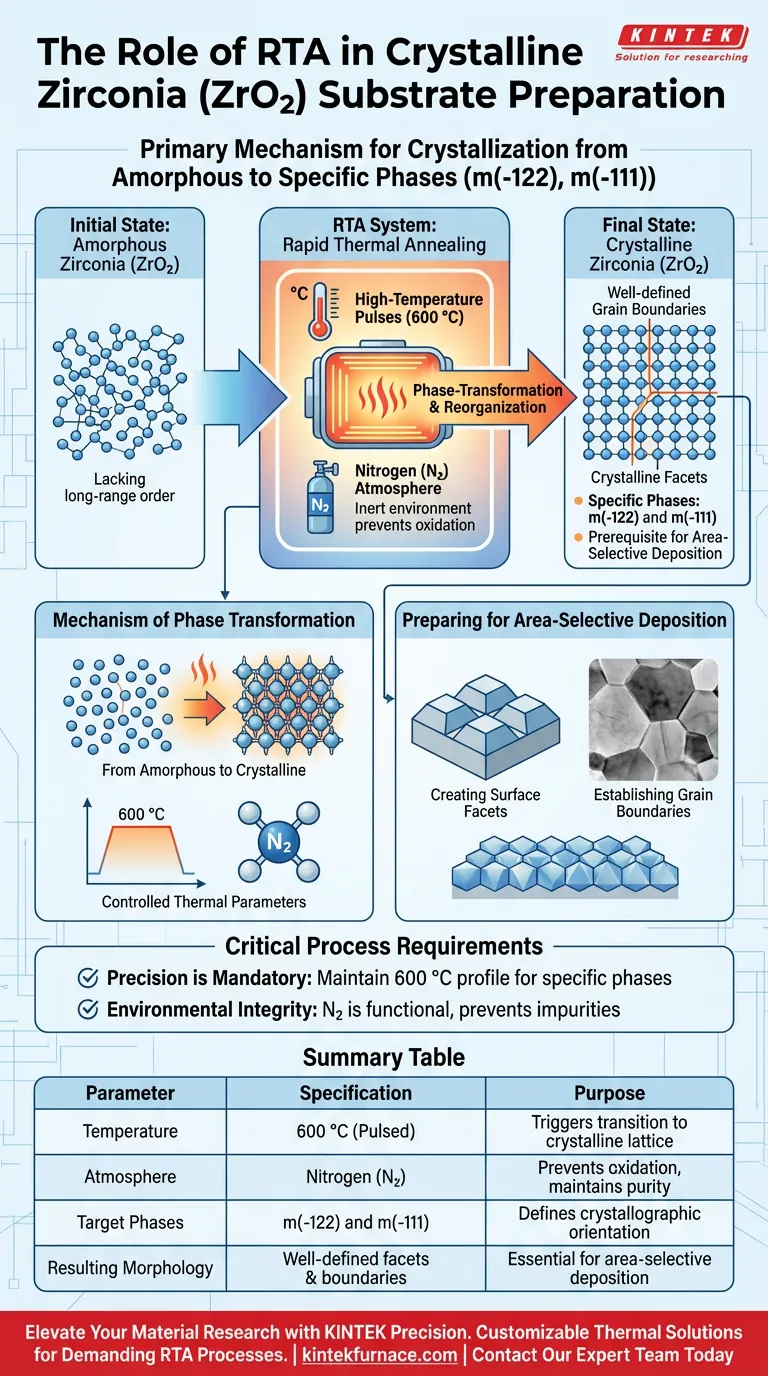

A Rapid Thermal Annealing (RTA) system serves as the primary mechanism for crystallizing Zirconia ($ZrO_2$) substrates. By utilizing high-temperature pulses, specifically at 600 °C in a nitrogen atmosphere, the system forces the material to transition from an amorphous structure to a specific crystalline state. This thermal treatment is not merely about heating; it is a precise engineering step required to prepare the surface for subsequent processing.

The RTA system functions as a phase-transformation tool, converting amorphous Zirconia into a crystalline form with well-defined grain boundaries and facets. This structural reorganization is a mandatory prerequisite for successful area-selective deposition experiments.

The Mechanism of Phase Transformation

From Amorphous to Crystalline

Initially, the Zirconia substrate exists in an amorphous state, lacking a defined long-range atomic order.

The RTA system applies thermal energy to reorganize this structure. This reorganization transforms the material into a rigid, crystalline lattice.

Controlled Thermal Parameters

The standard operating procedure involves high-temperature pulses of 600 °C.

To ensure the purity of the transformation, this process occurs within a nitrogen ($N_2$) atmosphere. This controlled environment prevents unwanted reactions with oxygen or moisture in the air during the heating cycle.

Achieving Specific Orientations

The crystallization process is not random; it drives the Zirconia toward specific crystallographic orientations.

According to standard protocols, the RTA treatment specifically targets the formation of m(-122) and m(-111) phases. These specific phases define the physical characteristics of the final substrate.

Preparing for Area-Selective Deposition

Creating Surface Facets

The transition to a crystalline state generates distinct crystalline facets on the surface of the Zirconia.

These facets provide the specific surface geometry required for advanced manufacturing techniques.

Establishing Grain Boundaries

Alongside facets, the thermal treatment develops well-defined grain boundaries.

These boundaries distinguish individual crystallites within the material. Without these distinct boundaries and facets, the substrate would lack the necessary morphology for effective area-selective deposition.

Critical Process Requirements

Precision is Mandatory

The effectiveness of the RTA process relies entirely on maintaining the specific 600 °C temperature profile.

Deviations in temperature could fail to produce the required m(-122) and m(-111) phases, rendering the substrate unsuitable for the next steps.

Environmental Integrity

The nitrogen atmosphere is not optional; it is a functional component of the system.

Compromising the inert environment during the thermal pulse can introduce impurities that alter surface chemistry and inhibit proper crystallization.

Making the Right Choice for Your Goal

When configuring an RTA system for Zirconia preparation, your specific objective dictates your quality control focus.

- If your primary focus is Crystallographic Accuracy: Verify that the thermal pulses remain stable at 600 °C to guarantee the formation of m(-122) and m(-111) phases.

- If your primary focus is Deposition Success: Inspect the substrate post-annealing to ensure well-defined grain boundaries and facets have formed before attempting area-selective deposition.

Mastering the thermal environment is the only way to ensure your substrate is truly ready for high-precision deposition.

Summary Table:

| Parameter | Specification | Purpose |

|---|---|---|

| Temperature | 600 °C (Pulsed) | Triggers transition from amorphous to crystalline lattice |

| Atmosphere | Nitrogen ($N_2$) | Prevents oxidation and maintains chemical purity |

| Target Phases | m(-122) and m(-111) | Defines the required crystallographic orientation |

| Resulting Morphology | Well-defined facets & boundaries | Essential for successful area-selective deposition |

Elevate Your Material Research with KINTEK Precision

Don't settle for inconsistent crystallization. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, and Vacuum furnaces, all customizable to your specific research requirements. Our systems ensure the rigid temperature control and environmental integrity necessary for the most demanding RTA processes and crystalline substrate preparation.

Ready to optimize your deposition results? Contact our expert team today to find the perfect high-temperature system for your laboratory.

Visual Guide

References

- Moo‐Yong Rhee, Il‐Kwon Oh. Area‐Selective Atomic Layer Deposition on Homogeneous Substrate for Next‐Generation Electronic Devices. DOI: 10.1002/advs.202414483

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of a high-pressure nitrogen environment? Speed and Efficiency in Wood Thermal Modification

- What are the energy-saving advantages of using a SHS system for tungsten carbide? Cut Energy Costs by up to 90%

- What is the purpose of using a rotary evaporator or a vacuum drying oven? Preserving SiC Powder Quality Post-Milling

- What is the role of a precision heating system in HEA synthesis? Achieve Atomic Uniformity at 220 °C

- What are the main types of sintering methods for metals, ceramics, and refractory intermetallic compounds powders? Optimize Your Material Processing

- Why is a vacuum or inert gas environment required during ball milling? Protect Your Nanocrystalline Alloy Purity

- Why is 10^-6 mbar pressure required for CZTS PLD? Ensure Pure, High-Efficiency Thin Film Deposition

- How does the lab oven drying process ensure the quality of bimetallic catalysts? Master Pore Stability & Dispersion