The primary purpose of using a rotary evaporator or vacuum drying oven is to rapidly remove solvents, such as ethanol, under controlled low-temperature and reduced-pressure conditions. This specific environment is essential to prevent the formation of severe hard agglomerates and to lock in the highly dispersed state of sintering additives achieved during the milling process.

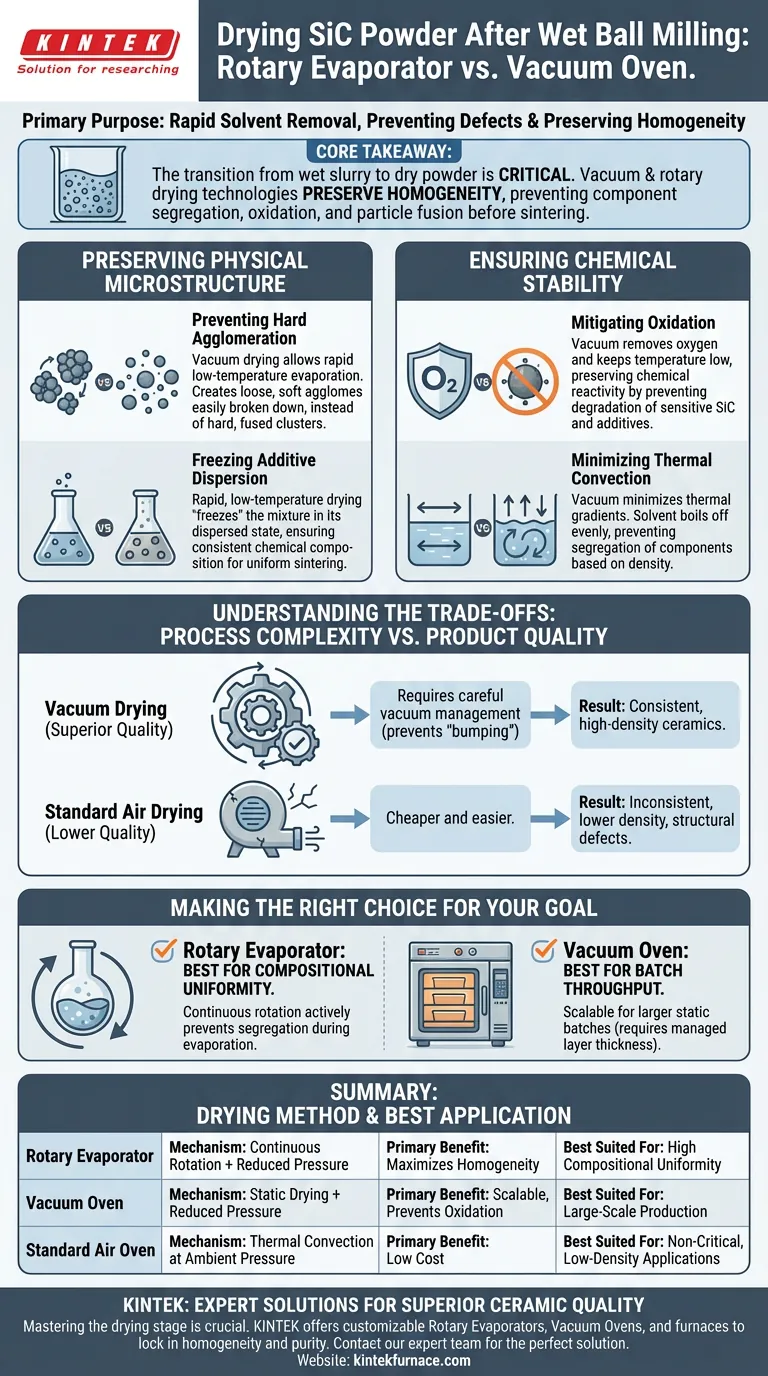

Core Takeaway The transition from a wet slurry to a dry powder is the most critical point for defect introduction in ceramic processing. Vacuum and rotary drying technologies are not just about removing liquid; they are about preserving the homogeneity created during milling by preventing component segregation, oxidation, and particle fusion before the sintering stage.

Preserving Physical Microstructure

Preventing Hard Agglomeration

The most immediate physical risk during drying is the formation of "hard agglomerates."

When solvents evaporate slowly at high temperatures or ambient pressure, particles tend to pack tightly together.

Vacuum drying lowers the boiling point of the solvent, allowing for rapid evaporation without high heat. This creates loose, soft agglomerates that are easily broken down, rather than hard, fused clusters that ruin moldability.

Freezing Additive Dispersion

Wet ball milling is used to achieve a perfect mixture of Silicon Carbide (SiC) and sintering additives.

If the drying process is slow or involves uneven thermal convection, these additives can separate or segregate from the SiC matrix.

Rapid, low-temperature drying effectively "freezes" the mixture in its dispersed state. This ensures that the chemical composition remains consistent throughout the entire batch, which is vital for uniform sintering later.

Ensuring Chemical Stability

Mitigating Oxidation

Silicon Carbide and its metallic sintering additives are sensitive to oxidation, particularly when heated in air.

Standard oven drying exposes the fine powder to oxygen at elevated temperatures, which can degrade the particle surfaces.

By operating in a vacuum, you remove the oxygen source. By lowering the boiling point, you keep the temperature below the threshold where rapid oxidation occurs. This preserves the chemical reactivity required for high-density sintering.

Minimizing Thermal Convection

In standard drying, heat often creates strong convection currents within the liquid slurry.

These currents can cause heavier particles to settle or lighter particles to float, undoing the mixing work done by the ball mill.

Vacuum drying minimizes these thermal gradients. The solvent boils off evenly and quickly, preventing the segregation of components based on density.

Understanding the Trade-offs

Process Complexity vs. Product Quality

While vacuum drying yields superior powder quality, it introduces complexity compared to standard air drying.

You must carefully manage vacuum levels to prevent "bumping" (violent boiling that can eject powder).

However, this complexity is a necessary trade-off. Simple air drying is cheaper and easier, but it frequently results in inconsistent ceramics with lower density and structural defects.

Making the Right Choice for Your Goal

The specific equipment you choose—rotary evaporator vs. static vacuum oven—depends on your specific processing scale and priority.

- If your primary focus is Compositional Uniformity: The rotary evaporator is superior because the continuous rotation actively prevents segregation while the solvent evaporates.

- If your primary focus is Batch Throughput: A vacuum drying oven is often more scalable for larger static batches, provided the layer thickness is managed to ensure even drying.

Ultimately, the goal is to produce a loose, homogeneous precursor powder that retains its chemical purity for the sintering furnace.

Summary Table:

| Drying Method | Mechanism | Primary Benefit | Best Suited For |

|---|---|---|---|

| Rotary Evaporator | Continuous rotation + reduced pressure | Maximizes homogeneity; prevents component segregation | High compositional uniformity |

| Vacuum Oven | Static drying + reduced pressure | Scalable batch processing; prevents oxidation | Large-scale production & throughput |

| Standard Air Oven | Thermal convection at ambient pressure | Low cost; simple operation | Non-critical, low-density applications |

Achieve superior ceramic quality by mastering the drying stage. At KINTEK, we understand that high-performance materials like Silicon Carbide require precision equipment to prevent defects. Backed by expert R&D and manufacturing, we offer customizable Rotary Evaporators, Vacuum Drying Ovens, and high-temp furnaces designed to lock in your powder's homogeneity and chemical purity. Don't let improper drying compromise your sintering results—contact our technical team today to find the perfect solution for your lab's unique needs.

Visual Guide

References

- Zipeng Li, Zhiqing Liang. Preparation of Aluminum Matrix Composites Reinforced with Hybrid MAX–MXene Particles for Enhancing Mechanical Properties and Tribological Performance. DOI: 10.3390/jcs9100552

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the purpose of adding wax organic binders to glass powder? Enhance Structural Integrity in Glass Sealing

- What are the advantages of using the foil-fiber-foil method for SiC/TB8 plates? Efficient SiC/TB8 Composite Production

- What are the primary applications of a constant temperature drying oven? Master Biochar Selenium-Modification

- How does a laboratory oven contribute to the hydrothermal treatment of graphene aerogels? Master High-Strength Synthesis

- What heat treatment conditions are required for SDSS2507 solution treatment? Achieve Precise 1100°C Thermal Profiles

- How does temperature control precision affect SC-NMNO crystal morphology? Master Thermal Fields for High-Quality Grains

- Why is a Cold Isostatic Press (CIP) utilized for LLTO samples? Achieve 98% Relative Density in Ceramics

- How can high-temperature furnace systems be used to evaluate and prevent slagging? Optimize Boiler Performance