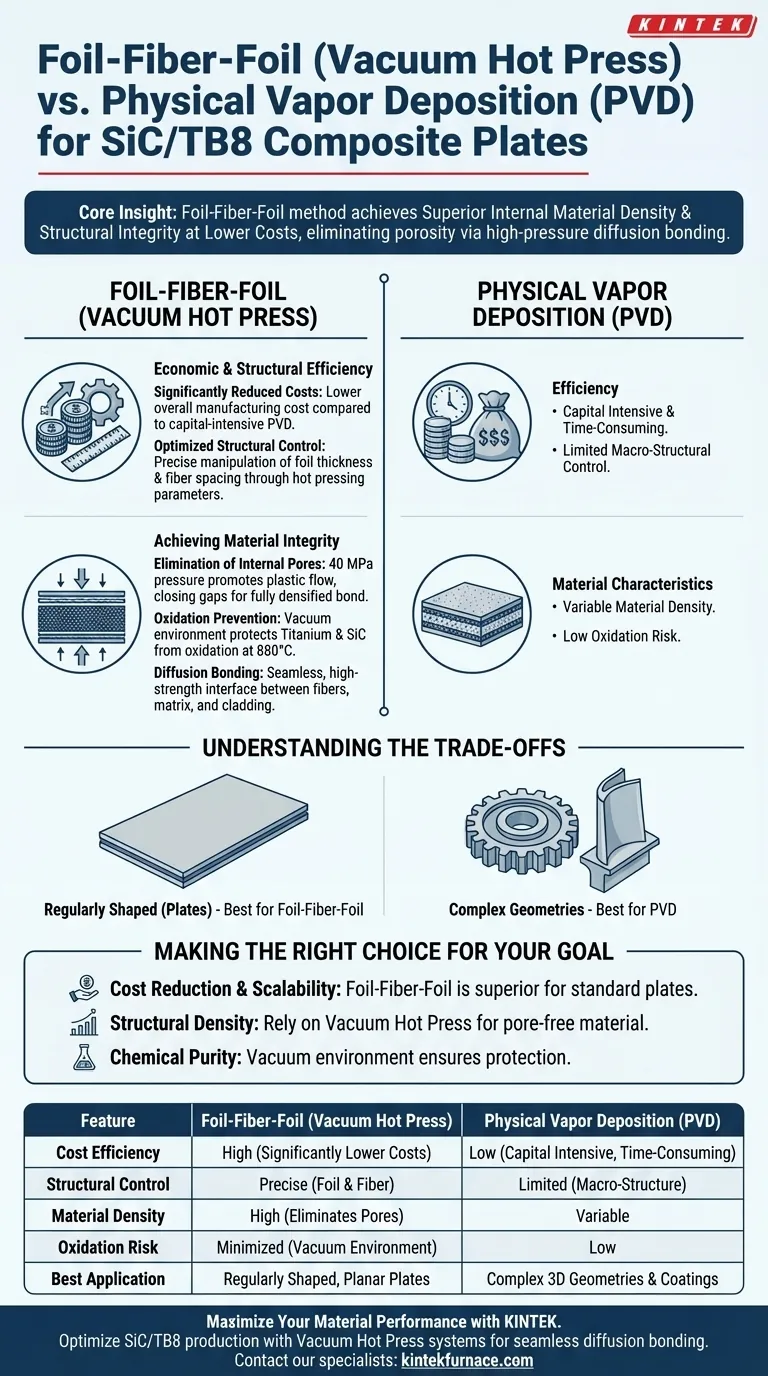

The foil-fiber-foil method combined with a vacuum hot press offers a distinct advantage in economic efficiency and structural control over Physical Vapor Deposition (PVD). This approach significantly lowers production costs while allowing for precise regulation of the composite's macro-structure, including foil thickness and fiber spacing, making it ideal for regularly shaped SiC/TB8 plates.

Core Insight: The foil-fiber-foil technique is not just a cost-saving measure; it is a method for achieving superior internal material density. By utilizing high-pressure diffusion bonding, it eliminates porosity and secures the structural integrity of the matrix without the high expense associated with vapor deposition processes.

Economic and Structural Efficiency

Significantly Reduced Costs

The most immediate advantage of the foil-fiber-foil method is its economic efficiency. Compared to the capital-intensive and time-consuming Physical Vapor Deposition (PVD) process, using a vacuum hot press drastically lowers the overall manufacturing cost for composite plates.

Optimized Structural Control

This method grants manufacturers exceptional control over the composite's internal architecture. By adjusting hot pressing parameters, you can conveniently manipulate foil thickness and fiber spacing.

Macro-Structural Organization

Beyond individual layers, the process facilitates better organization of the material's overall structure. This ensures that the resulting SiC/TB8 plates meet specific mechanical requirements through precise arrangement of the fiber and matrix components.

Achieving Material Integrity

Elimination of Internal Pores

The vacuum hot press applies substantial pressure (e.g., 40 MPa) to the laminate. This pressure promotes plastic flow in the matrix metal, effectively closing gaps and eliminating internal pores to create a fully densified bond.

Oxidation Prevention

The high-temperature environment (880°C) required for bonding creates a risk of material degradation. However, the vacuum environment of the hot press effectively prevents the oxidation of both the titanium alloy matrix and the silicon carbide fibers during processing.

Diffusion Bonding

The combination of heat and pressure facilitates diffusion bonding. This results in a seamless, high-strength interface between the fibers, the matrix, and the cladding materials, which is critical for the load-bearing performance of the composite.

Understanding the Trade-offs

Geometry Limitations

While highly effective for plates, this method is specifically noted as suitable for regularly shaped composites.

The dependence on applying uniform pressure via a press makes it less adaptable for complex, non-planar, or highly intricate 3D geometries compared to deposition methods that can coat irregular surfaces.

Making the Right Choice for Your Goal

- If your primary focus is cost reduction and scalability: The foil-fiber-foil method is superior to PVD, offering significantly lower operational costs for producing standard plates.

- If your primary focus is structural density: Rely on the vacuum hot press to induce plastic flow and diffusion bonding, ensuring a pore-free, densified material.

- If your primary focus is chemical purity: The vacuum environment is essential to protect the titanium matrix and SiC fibers from oxidation at high processing temperatures.

By prioritizing the foil-fiber-foil method for planar applications, you achieve a balance of high material quality and economic feasibility that PVD cannot match for this specific use case.

Summary Table:

| Feature | Foil-Fiber-Foil (Vacuum Hot Press) | Physical Vapor Deposition (PVD) |

|---|---|---|

| Cost Efficiency | High (Significantly lower production costs) | Low (Capital intensive and time-consuming) |

| Structural Control | Precise control of foil thickness & fiber spacing | Limited control over macro-structure |

| Material Density | High (Eliminates pores via 40MPa pressure) | Variable |

| Oxidation Risk | Minimized (Controlled vacuum environment) | Low |

| Best Application | Regularly shaped, planar composite plates | Complex 3D geometries and coatings |

Maximize Your Material Performance with KINTEK

Ready to optimize your SiC/TB8 composite production? KINTEK provides industry-leading Vacuum Hot Press systems and high-temp furnace solutions designed to eliminate porosity and ensure seamless diffusion bonding. Backed by expert R&D and manufacturing, we offer customizable Vacuum, Muffle, Tube, and CVD systems tailored to your unique laboratory or industrial needs.

Lower your production costs and achieve superior material density today. Contact our specialists now to find the perfect system for your application!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the advantages of ascorbic acid over glucose in LFP synthesis? Achieve Superior Purity and Crystallinity

- What are the primary advantages of using a downdraft fixed-bed reactor for co-gasification? Pure Syngas Made Simple

- How do heating devices and alkaline impregnation tanks coordinate in biochar activation for maximum adsorption?

- What is quenching, and why is it important? Achieve Superior Material Hardness and Strength

- What additional benefits do vacuum chambers provide beyond environmental control? Enhance Material Purity and Process Efficiency

- How does a vacuum drying oven contribute to stable lithium-selenium battery electrodes? Ensure Purity and Performance

- What is the function of the annealing furnace? Strategically Control Material Properties for Reliability

- How does the introduction of silicon dioxide (SiO2) facilitate the preparation of pure-phase olivine phosphors via HTSSR?