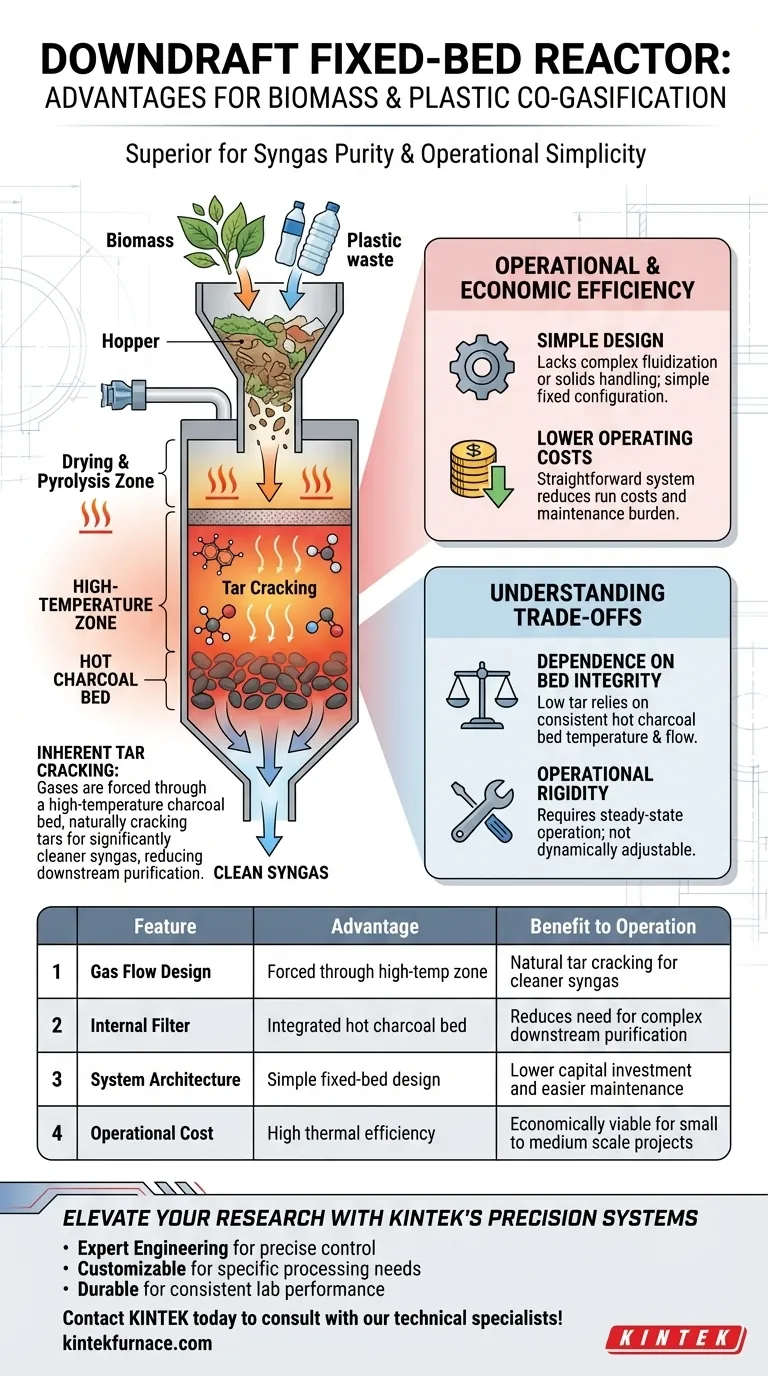

The primary advantages of a downdraft fixed-bed reactor for biomass and plastic co-gasification are its inherent ability to produce clean syngas, its operational simplicity, and its cost-effectiveness. The specific "downdraft" configuration forces gases through a high-temperature zone, effectively solving the issue of tar contamination that plagues many other gasification methods.

Core Takeaway: The downdraft fixed-bed reactor is the superior choice when syngas purity is the priority. Its internal architecture utilizes a hot charcoal bed to naturally crack tars before they exit the system, delivering a cleaner product with significantly lower operating complexity than alternative designs.

Solving the Tar Challenge: The Quality Advantage

The most critical technical advantage of the downdraft reactor is its ability to minimize impurities in the final gas output.

The Mechanism of Tar Cracking

In a downdraft configuration, the produced gases are not allowed to exit immediately. Instead, they are forced to pass downward through a high-temperature zone.

The Role of the Hot Charcoal Bed

This high-temperature zone consists of a hot charcoal bed. As the gas moves through this bed, the charcoal acts as both a thermal and chemical agent.

Significantly Cleaner Syngas

The heat and contact with the charcoal promote the cracking of tars. This breaks down heavy, problematic contaminants into useful combustible gases, resulting in a significantly cleaner syngas that requires less downstream purification.

Operational and Economic Efficiency

Beyond the chemistry, the physical design of the reactor offers distinct project management benefits.

Design Simplicity

The downdraft fixed-bed reactor is preferred for its simple design. It lacks the complex fluidization machinery or intricate solids handling systems required by fluidized bed or entrained flow reactors.

Lower Operating Costs

Because the design is straightforward, the system is generally less expensive to run. The low operating costs make it an attractive option for projects where budget constraints or ease of maintenance are key factors.

Understanding the Trade-offs

While the downdraft reactor excels in purity and simplicity, it is important to recognize the operational constraints inherent in its design.

Dependence on Bed Integrity

The system's primary advantage—low tar—is entirely dependent on the hot charcoal bed. If the bed temperature fluctuates or the flow through the bed becomes uneven, the tar-cracking efficiency will drop immediately.

Operational Rigidity

The "simple design" implies a fixed configuration. Unlike more complex reactors that can be dynamically adjusted, a fixed-bed system relies on consistent feed and steady-state operation to maintain the charcoal bed's effectiveness.

Making the Right Choice for Your Goal

When evaluating reactor types for co-gasification, align the reactor's strengths with your specific project constraints.

- If your primary focus is Syngas Quality: Select the downdraft reactor to leverage the hot charcoal bed for maximum tar reduction and cleaner output.

- If your primary focus is Budget and Maintenance: Choose this reactor for its simple design and low operating costs, which reduce the burden on technical staff and capital expenditure.

By prioritizing the downdraft configuration, you effectively use the process's own byproducts (charcoal) to purify the result, creating a highly efficient loop for co-gasification.

Summary Table:

| Feature | Advantage | Benefit to Operation |

|---|---|---|

| Gas Flow Design | Forced through high-temp zone | Natural tar cracking for cleaner syngas |

| Internal Filter | Integrated hot charcoal bed | Reduces need for complex downstream purification |

| System Architecture | Simple fixed-bed design | Lower capital investment and easier maintenance |

| Operational Cost | High thermal efficiency | Economically viable for small to medium scale projects |

Elevate Your Research with KINTEK’s Precision Systems

Are you looking to optimize your co-gasification process or material synthesis? KINTEK provides industry-leading lab equipment tailored for high-performance thermal applications. Backed by expert R&D and manufacturing, we offer high-temperature Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique research specifications.

Our value to you:

- Expert Engineering: Systems designed for uniform heating and precise control.

- Customization: Flexible configurations for specific biomass and plastic processing needs.

- Durability: Robust construction for consistent, long-term laboratory performance.

Contact KINTEK today to consult with our technical specialists and find the perfect high-temperature solution for your lab!

Visual Guide

References

- Mariana Busto, Carlos R. Vera. Catalytic and Non-Catalytic Co-Gasification of Biomass and Plastic Wastes for Energy Production. DOI: 10.3390/catal15090844

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the temperature advantages of using Cathodic Arc Deposition (CAD)? Boost Film Hardness at Lower Temperatures

- What are the key features of a batch furnace? Unlock Precision and Flexibility in Heat Treatment

- Why is precise temperature control programming indispensable for SFC research? Optimize Sintering Process Success

- What is the purpose of using an industrial oven for flax fiber pretreatment? Ensure Superior Composite Integrity

- How do the rotational and orbital movements of the sample stage contribute to the uniformity of coatings on Zircaloy?

- Why is a drying oven with precise temperature control necessary for NiO-CGO anode supports? Ensure Cell Integrity

- How does the ramp rate affect LDO properties? Master Rapid Thermal Control for 69% More Efficiency

- What is the significance of pre-equilibrating samples in silicate studies? Maximize Experimental Efficiency