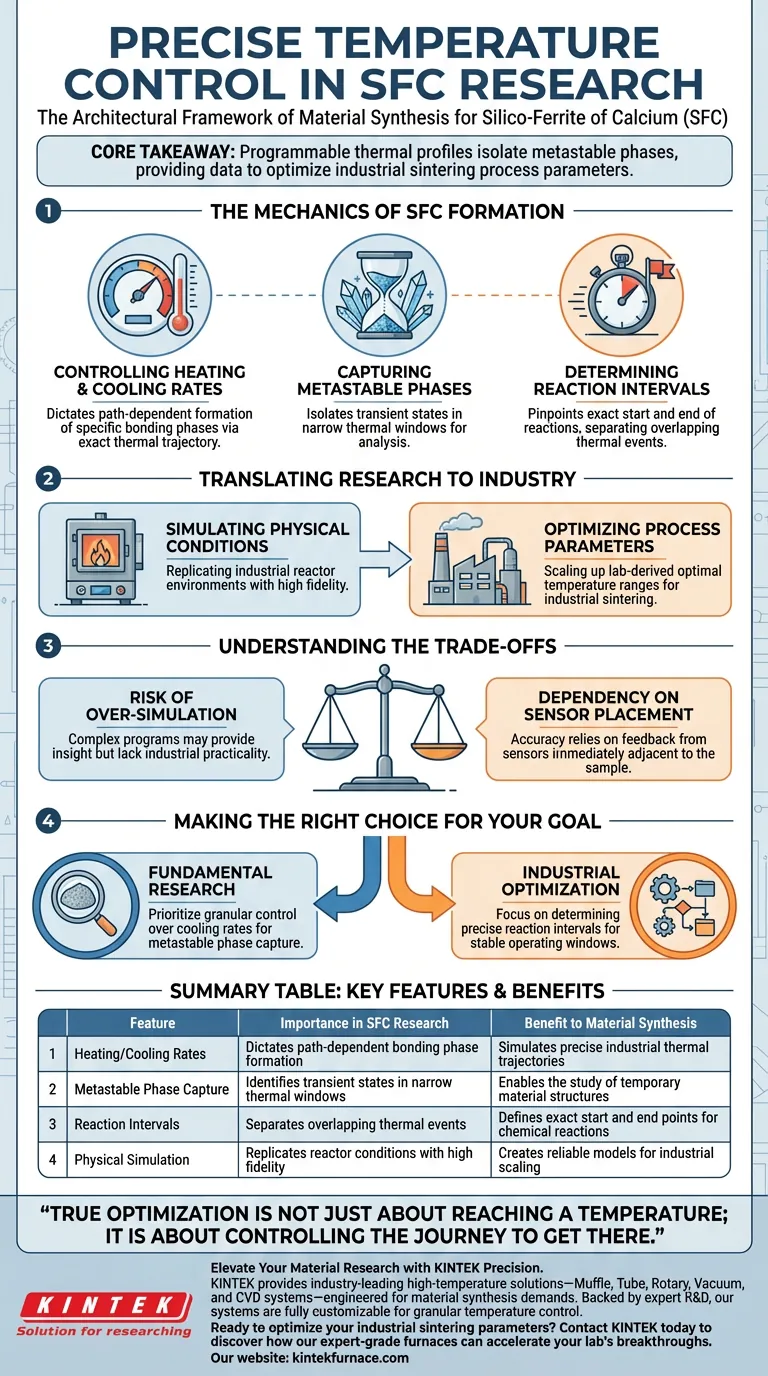

Precise temperature control is the architectural framework of material synthesis. In the context of Silico-Ferrite of Calcium (SFC) research, high-temperature equipment is indispensable because it enables the execution of specific heating and cooling rates required to capture transient material states. Without this programmable precision, it is impossible to accurately simulate the physical conditions necessary to define reaction intervals and determine the optimal formation of bonding phases.

Core Takeaway: The ability to program exact thermal profiles allows researchers to isolate and study metastable phases that would otherwise be missed. This data is the scientific prerequisite for defining the optimal temperature ranges used to optimize industrial sintering process parameters.

The Mechanics of SFC Formation

To understand the necessity of precision, one must look beyond simple temperature setpoints and focus on the dynamic behavior of the material during thermal processing.

Controlling Heating and Cooling Rates

SFC research requires more than maintaining a static temperature; it demands dynamic control over the thermal trajectory.

Programmable equipment allows researchers to dictate the exact speed at which the sample heats up or cools down.

This capability is critical because the formation of specific bonding phases is often path-dependent, relying heavily on the rate of thermal change.

Capturing Metastable Phases

The formation of SFC often involves transient metastable phases.

These phases are temporary states that appear effectively only under specific thermal conditions before transforming into stable phases.

Precise programming allows the equipment to navigate these narrow windows, "freezing" or capturing these phases for analysis before they disappear.

Determining Reaction Intervals

High-precision equipment separates overlapping thermal events by defining clear reaction intervals.

By strictly controlling the temperature program, researchers can pinpoint exactly when a reaction begins and ends.

This clarity prevents the misinterpretation of data that can occur when thermal gradients cause reactions to blur together.

Translating Research to Industry

The ultimate value of this precision lies in its application to large-scale manufacturing and processing.

Simulating Physical Conditions

Laboratory equipment must replicate the specific physical conditions found in industrial reactors, but with higher fidelity.

By simulating these conditions accurately, researchers create a reliable model of how the material behaves under stress.

Optimizing Process Parameters

The data derived from these controlled experiments provides a scientific basis for the industrial sintering process.

Once the optimal temperature range for SFC formation is identified in the lab, these parameters can be scaled up.

This ensures that the industrial process is tuned to maximize the yield of desired bonding phases, improving the structural integrity of the final product.

Understanding the Trade-offs

While high-precision programming is powerful, it introduces complexity that must be managed to ensure data validity.

The Risk of Over-Simulation

There is a potential pitfall in creating thermal programs that are too complex to be replicated in an industrial setting.

Data derived from highly exotic heating profiles may provide academic insight but fail to offer practical parameters for mass production.

Dependency on Sensor Placement

Precision programming is only as good as the feedback from the temperature sensors.

If sensors are not positioned immediately adjacent to the sample (e.g., in a dedicated thermowell), systemic deviation can occur.

This means the "programmed" temperature and the "actual" sample temperature may diverge, rendering the precise heating rate theoretically correct but practically inaccurate.

Making the Right Choice for Your Goal

When configuring high-temperature equipment for SFC analysis, align your approach with your specific objective.

- If your primary focus is Fundamental Research: Prioritize equipment that offers granular control over cooling rates to capture and identify transient metastable phases.

- If your primary focus is Industrial Optimization: Focus on determining the precise reaction intervals to define the widest possible stable operating window for the sintering plant.

True optimization is not just about reaching a temperature; it is about controlling the journey to get there.

Summary Table:

| Feature | Importance in SFC Research | Benefit to Material Synthesis |

|---|---|---|

| Heating/Cooling Rates | Dictates path-dependent bonding phase formation | Simulates precise industrial thermal trajectories |

| Metastable Phase Capture | Identifies transient states in narrow thermal windows | Enables the study of temporary material structures |

| Reaction Intervals | Separates overlapping thermal events | Defines exact start and end points for chemical reactions |

| Physical Simulation | Replicates reactor conditions with high fidelity | Creates reliable models for industrial scaling |

Elevate Your Material Research with KINTEK Precision

Don't let thermal inconsistency compromise your SFC research. KINTEK provides industry-leading high-temperature solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—engineered for the rigorous demands of material synthesis.

Backed by expert R&D and manufacturing, our systems are fully customizable to provide the granular temperature control needed to capture metastable phases and define optimal reaction intervals.

Ready to optimize your industrial sintering parameters? Contact KINTEK today to discover how our expert-grade furnaces can accelerate your lab's breakthroughs.

Visual Guide

References

- <i>In-Situ</i> X-ray Diffraction Analysis Reveals Complex Calcium Ferrite Phase Formation during Heating and Cooling of Silico-Ferrite of Calcium (SFC) Compositions. DOI: 10.2355/isijinternational.isijint-2025-121

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a high-temperature sintering furnace ensure structural integrity? Expert Thermal Management Guide

- How does the pre-oxidation process affect high-temperature alloys? Enhancing Surface Integrity for Steam Cracking

- What is the function of a laboratory drying oven in processing NdFeB waste? Ensure Purity in Rare Earth Recovery

- How is the success of stress-relief heat treatment in AlSi10Mg verified? Ensure Part Integrity with XRD

- What is the purpose of using an industrial oven for flax fiber pretreatment? Ensure Superior Composite Integrity

- What role does an oscillating heating stage play in WO3 thin film growth? Control Kinetics and Crystal Orientation

- Why is temperature gradient management necessary for high-temperature impedance measurements? Master Thermal Precision

- What is the primary function of a forced convection oven in plant sample preparation? Ensure Accurate Data Every Time