The verification of stress-relief heat treatment in additively manufactured AlSi10Mg components is accomplished using X-ray diffraction (XRD). This non-destructive testing method performs micro-area analysis at multiple angles to accurately measure the residual stress states within the part after it has exited the heat treatment equipment.

Core Takeaway

The laser melting process used to create AlSi10Mg parts inherently generates dangerous tensile residual stresses. XRD provides the scientific data required to prove that thermal processes, such as low-temperature aging, have effectively neutralized these stresses and restored the component's structural integrity.

The Mechanics of Verification via XRD

To understand how success is verified, one must look at how XRD quantifies the invisible internal forces within the metal.

Micro-Area Analysis

The verification process does not simply look at the part as a whole. Instead, it utilizes micro-area analysis to target specific regions of the component.

This allows engineers to determine stress levels at precise locations that may be critical to performance.

Multi-Angle Measurement

A single snapshot is insufficient for accurate stress determination. The XRD technique analyzes the material from multiple angles.

By shifting the measurement perspective, the equipment can calculate the strain in the crystal lattice structure, which correlates directly to residual stress.

Quantifying Stress States

The ultimate output of this process is a measurement of residual stress states.

This data confirms whether the metal remains under tension (which is dangerous) or if the stress has been relieved to a neutral or compressive state.

Why Verification is Critical for AlSi10Mg

The verification process is not just a formality; it is a response to the physics of the manufacturing process.

Counteracting Laser Melting Effects

The primary reference highlights that the laser melting process generates significant tensile residual stresses.

Rapid heating and cooling cycles during printing lock these stresses into the material, creating a potential failure point before the part is even used.

Validating Thermal Processes

Heat treatments, such as low-temperature aging, are applied to relax these locked-in forces.

XRD serves as the "scientific tool" to confirm that these specific thermal cycles actually worked as intended.

Ensuring Structural Integrity

Without verification, the structural integrity of the component is merely an assumption.

XRD transforms this assumption into verified fact, ensuring the part can withstand its operational environment without warping or cracking.

Understanding the Trade-offs

While XRD is the standard for verification, it is important to understand the practical constraints of the method.

localized vs. Volumetric

XRD typically analyzes the surface or near-surface of the component using micro-area analysis.

This means it provides excellent data for specific points, but it does not inherently scan the deep internal volume of a thick part in a single pass.

Process Complexity

This is a sophisticated scientific technique, not a simple "pass/fail" gauge.

It requires specialized equipment and precise calibration to interpret the diffraction patterns at multiple angles correctly.

Making the Right Choice for Your Goal

When integrating stress-relief verification into your manufacturing workflow, consider your specific requirements.

- If your primary focus is process validation: Use XRD to periodically benchmark your heat treatment cycles (e.g., low-temperature aging) to ensure they consistently mitigate tensile stresses.

- If your primary focus is critical part safety: Use XRD micro-area analysis on high-stress geometric features to guarantee structural integrity where it matters most.

Verification via X-ray diffraction moves stress relief from a theoretical step to a measurable, quality-assured engineering reality.

Summary Table:

| Verification Factor | Method/Detail | Purpose |

|---|---|---|

| Primary Tool | X-ray Diffraction (XRD) | Non-destructive residual stress measurement |

| Analysis Type | Micro-area Analysis | Target specific critical regions of the component |

| Measurement | Multi-angle Scanning | Calculate lattice strain to determine stress states |

| Stress Goal | Neutralize Tensile Stress | Prevent warping, cracking, and structural failure |

| Thermal Process | Low-temperature Aging | Relieve stresses locked in by laser melting |

Guarantee the Integrity of Your Additive Components

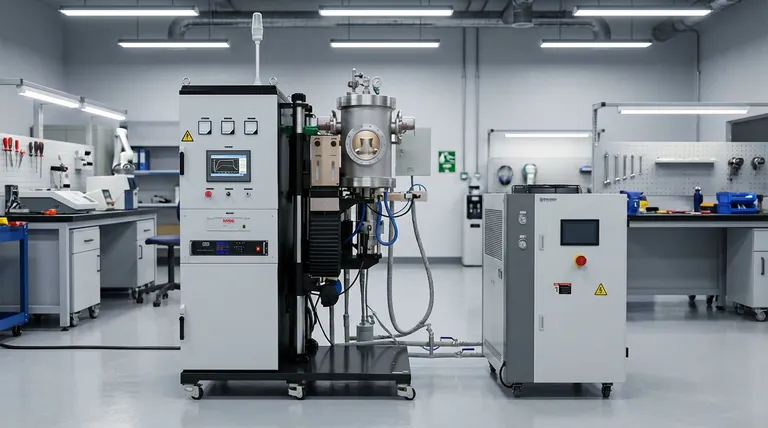

Don't leave the structural safety of your AlSi10Mg parts to chance. KINTEK provides the high-precision thermal solutions necessary to neutralize dangerous residual stresses. Backed by expert R&D and world-class manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with other lab high-temperature furnaces—all fully customizable to meet your unique metallurgical needs.

Ensure your heat treatment cycles are consistent, measurable, and effective. Contact KINTEK today to discuss how our specialized equipment can optimize your additive manufacturing workflow.

Visual Guide

References

- Busisiwe J. Mfusi, Ntombi Mathe. Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching. DOI: 10.3390/met14030292

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What are the drawbacks of large industrial ovens? Avoid Costly Inefficiencies and Boost Productivity

- What is the impact of microwave power on the synthesis of 2D metal oxides? Master High-Speed Material Production

- What role does a Teflon-lined stainless steel autoclave play in the hydrothermal synthesis of PtLaOx@S-1 catalysts?

- What are the advantages of using a vacuum low-temperature microwave-assisted pyrolysis system for LCP? (Enhanced Guide)

- What is the significance of an in-situ high-temperature heating stage? Unlock Real-Time Crystal Structure Insights

- What are the process advantages of using an electric melting furnace with an adjustable thermostat? Optimize Copper Scrap Refining

- What are the core technical advantages of using SPS for Titanium Diboride ceramics? Achieve High Density & Fine Grains

- What role does an industrial-grade POCl3 diffusion furnace system play in DOSS? Master Quantitative Phosphorus Control