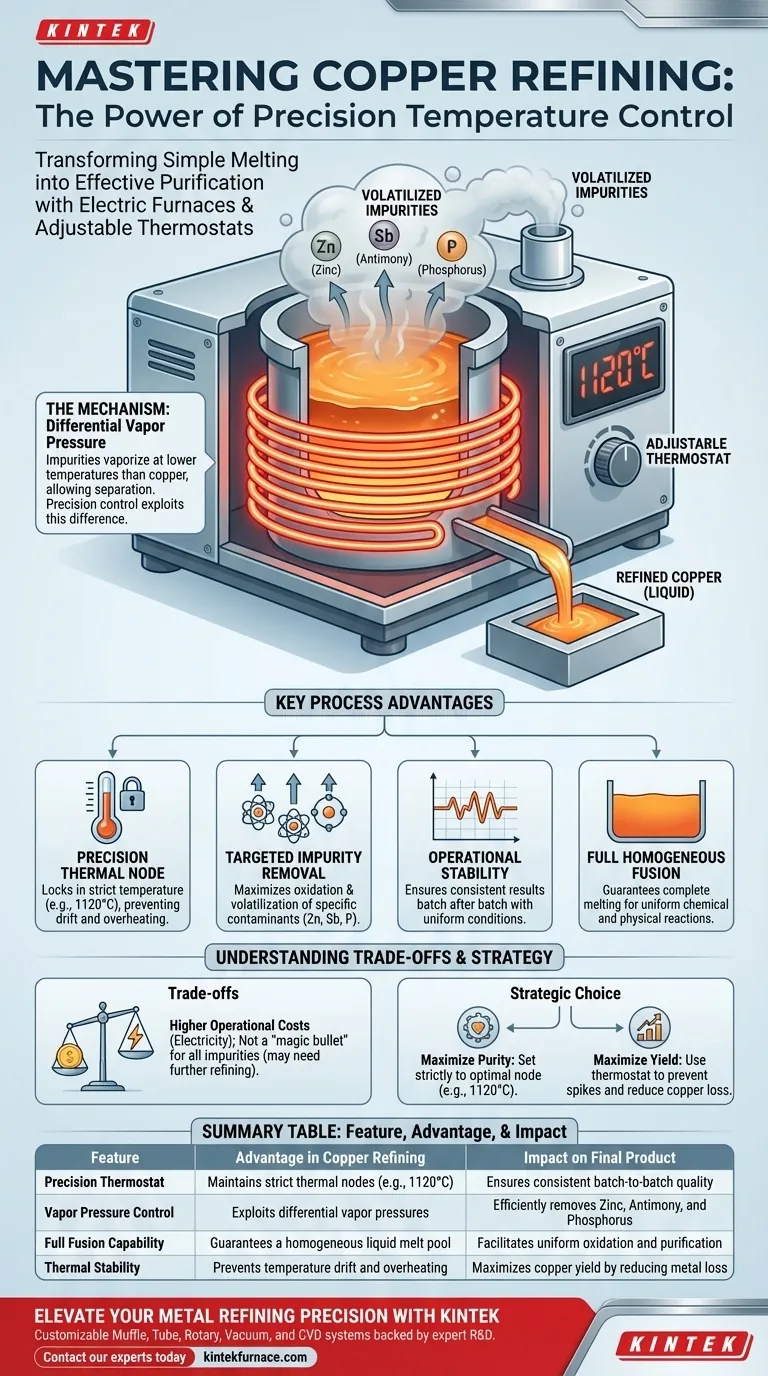

Precision temperature control is the specific mechanism that transforms simple melting into effective purification. By utilizing an electric melting furnace equipped with an adjustable thermostat, operators can lock in a strict thermal node, such as 1120°C. This exactitude ensures the copper scrap is fully fused while simultaneously creating the specific thermodynamic conditions required to separate impurities based on their unique vapor pressures.

The core advantage of this setup is the ability to maintain the melt at the precise threshold where volatile impurities like zinc, antimony, and phosphorus are maximized for removal through oxidation and volatilization, without overheating the base metal.

The Mechanics of Thermal Purification

Exploiting Vapor Pressure Differences

The fundamental principle behind this process is differential vapor pressure. Different elements transition from liquid to gas at different temperatures.

By using an adjustable thermostat, you can maintain the furnace temperature at a specific point where the vapor pressure of impurities is significantly higher than that of copper. This forces contaminants to volatilize (turn into gas) and exit the melt, while the copper remains liquid.

Targeting Specific Impurities

The primary reference highlights three specific contaminants that are effectively managed through this method: zinc, antimony, and phosphorus.

The adjustable thermostat allows the furnace to hold the melt in a state that promotes the oxidation and subsequent volatilization of these elements. Without this control, temperature fluctuations could either fail to remove these impurities or lead to excessive copper loss.

Operational Stability and Efficiency

Maintaining the Optimal Thermal Node

Efficiency in pyrometallurgy relies on hitting a "sweet spot." The primary reference identifies 1120°C as an optimal node for this specific application.

An adjustable thermostat is critical because it prevents the drift associated with less precise heating methods. It locks the process at this exact temperature, ensuring consistent results batch after batch.

Ensuring Complete Fusion

Before refining can take place, the scrap must be entirely liquid.

The thermostat ensures the system reaches and sustains the melting point required for full fusion. This creates a homogeneous melt pool, which is necessary for the chemical reactions (oxidation) and physical changes (volatilization) to occur uniformly throughout the batch.

Understanding the Trade-offs

The Cost of Precision

While electric furnaces provide superior control compared to fuel-fired alternatives, they often come with higher operational costs related to electricity consumption. Maintaining a strict temperature node requires constant energy regulation, which can be resource-intensive depending on local energy prices.

Process Isolation Limits

While an adjustable thermostat significantly aids in removing zinc, antimony, and phosphorus, it is not a "magic bullet" for all impurities.

Thermal control exploits vapor pressure, but impurities with boiling points or vapor pressures very similar to copper, or those that do not oxidize easily, may require additional chemical fluxing or subsequent refining stages (such as electrolysis) to achieve high-grade purity.

Making the Right Choice for Your Goal

To maximize the value of your electric melting furnace, align your temperature strategy with your specific refining targets:

- If your primary focus is Purity: Set the thermostat strictly to the optimal node (e.g., 1120°C) to maximize the vapor pressure differential and drive off zinc, antimony, and phosphorus.

- If your primary focus is Yield: Use the thermostat to prevent temperature spikes that could lead to the unnecessary vaporization or oxidation of the copper itself.

Mastering the thermostat turns a standard melting process into a sophisticated, high-efficiency separation system.

Summary Table:

| Feature | Advantage in Copper Refining | Impact on Final Product |

|---|---|---|

| Precision Thermostat | Maintains strict thermal nodes (e.g., 1120°C) | Ensures consistent batch-to-batch quality |

| Vapor Pressure Control | Exploits differential vapor pressures | Efficiently removes Zinc, Antimony, and Phosphorus |

| Full Fusion Capability | Guarantees a homogeneous liquid melt pool | Facilitates uniform oxidation and purification |

| Thermal Stability | Prevents temperature drift and overheating | Maximizes copper yield by reducing metal loss |

Elevate Your Metal Refining Precision with KINTEK

Don't let temperature fluctuations compromise your purity and yield. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of pyrometallurgical refining. Whether you are targeting specific impurity removal or maximizing material recovery, our advanced heating solutions provide the exact thermal control your laboratory or industrial process requires.

Ready to optimize your high-temperature processes? Contact our experts today to find the perfect customizable furnace for your unique needs.

Visual Guide

References

- Omar Choukri, Souadi Taibi. Achieving industrial-grade purity in recycled copper scrap: Pretreatment and fire refining approach. DOI: 10.46793/tribomat.2025.008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

People Also Ask

- What are the primary process advantages of using a continuous high-temperature tunnel furnace for copper tube brazing?

- How does a high-temperature sintering furnace influence ZnO nanotube sensors? Unlock Peak Sensitivity and Stability

- How does a constant temperature drying oven contribute to MgTiO3-CaTiO3 ceramic slurry? Optimize Your Precursor Quality

- What are the advantages of using a customized multimode microwave reaction furnace? Boost Synthesis Speed by 90%

- What is the function of an industrial resistance furnace in HPDC magnesium melting? Master Thermal Precision

- What is the function of a high-pressure hydrothermal reactor in hydrochar synthesis? Unlock Biomass Transformation

- What core role does a magnetron sputtering system play in CrSiN-Y PVD? Unlock High-Performance Coating Precision

- Why is precise temperature control critical in a calcination furnace for LiMnO2? Achieve High-Purity Crystal Structures