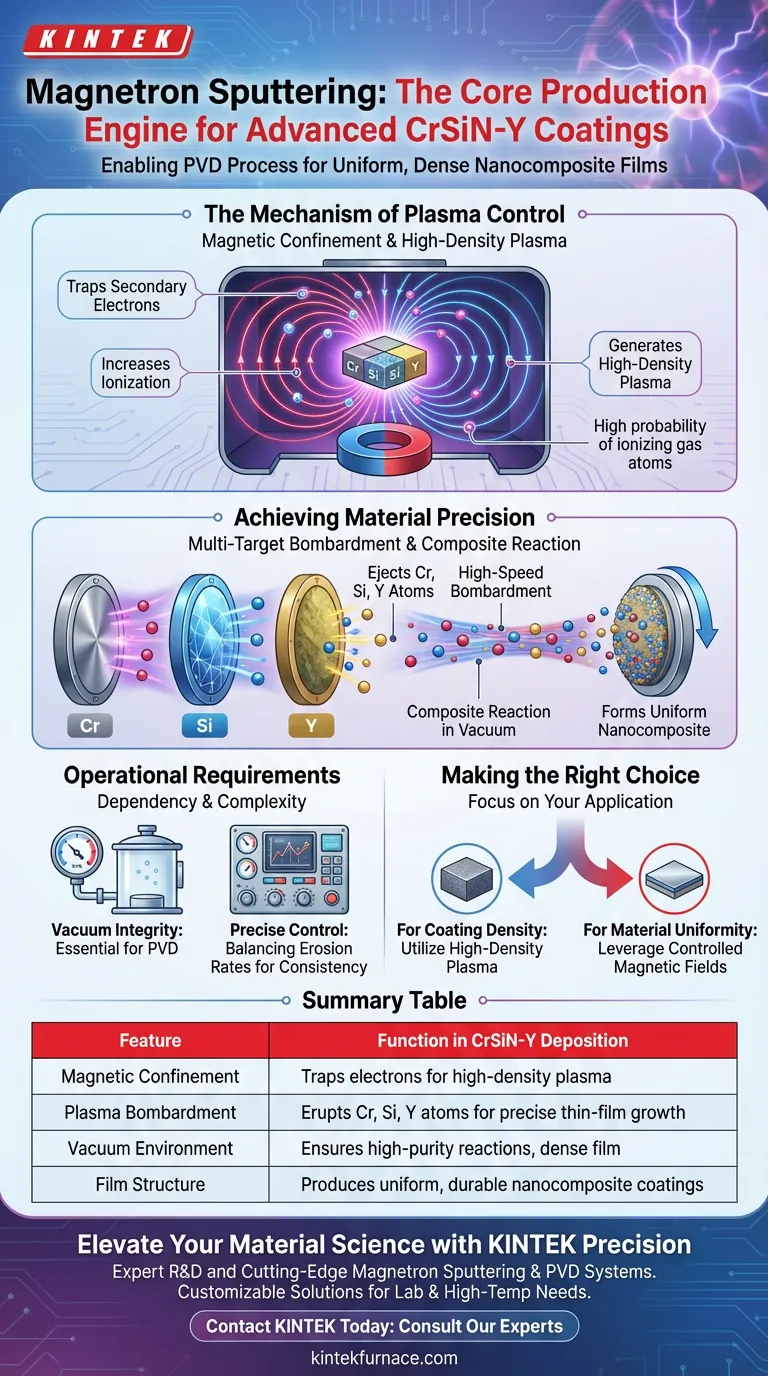

The magnetron sputtering system serves as the primary production engine for creating advanced CrSiN-Y coatings. It operates by utilizing strictly controlled magnetic fields to confine secondary electrons, thereby generating the high-density plasma required to bombard chromium, silicon, and yttrium targets for precise thin-film deposition.

By enabling the high-speed bombardment of multiple metal targets in a vacuum, this system facilitates the composite reaction necessary to build films with uniform composition, dense organization, and a specialized nanocomposite structure.

The Mechanism of Plasma Control

To understand the quality of CrSiN-Y coatings, you must first understand how the magnetron sputtering system manages energy and matter.

Magnetic Confinement of Electrons

The core differentiator of this system is its use of controlled magnetic fields.

These fields are designed to trap and confine secondary electrons near the target surface.

Generation of High-Density Plasma

By confining these electrons, the system significantly increases the probability of ionizing gas atoms.

This process creates a high-density plasma, which is the fundamental medium used to erode the material targets.

Achieving Material Precision

The system acts as a high-precision transfer mechanism, moving atoms from a solid source to the substrate with specific structural characteristics.

Multi-Target Bombardment

The high-density plasma bombards specific targets composed of chromium (Cr), silicon (Si), and yttrium (Y).

This bombardment ejects metal atoms from the targets at high speeds, initiating the deposition process.

Composite Reaction in Vacuum

The actual formation of the CrSiN-Y coating occurs through a composite reaction within a vacuum environment.

Because the process happens in a vacuum, it minimizes contamination and allows for the unobstructed travel of sputtered atoms.

Formation of Nanocomposite Structures

The result of this high-speed, controlled deposition is a functional thin film.

This film is characterized by a uniform composition and dense organization, ultimately forming a robust nanocomposite structure on the substrate.

Operational Requirements and Considerations

While the magnetron sputtering system offers high precision, the description of its operation implies specific operational requirements that must be managed.

Dependency on Vacuum Integrity

The process relies entirely on a vacuum environment to facilitate the composite reaction.

This implies that the quality of the final coating is directly tethered to the system's ability to maintain and monitor low-pressure conditions.

Complexity of Control

Achieving a "uniform composition" from multiple targets (Cr, Si, Y) requires precise sputtering control.

Balancing the erosion rates of three different materials to create a consistent nanocomposite structure demands rigorous process management.

Making the Right Choice for Your Application

The magnetron sputtering system is not just a tool; it is a precision instrument for synthesizing complex materials.

- If your primary focus is coating density: Rely on this system’s ability to generate high-density plasma, which directly correlates to the dense organization of the final film.

- If your primary focus is material uniformity: Leverage the controlled magnetic fields to ensure stable sputtering rates across the Cr, Si, and yttrium targets.

Mastering the magnetic confinement parameters of this system is the key to unlocking the full potential of CrSiN-Y nanocomposite coatings.

Summary Table:

| Feature | Function in CrSiN-Y Deposition |

|---|---|

| Magnetic Confinement | Traps secondary electrons to generate high-density plasma. |

| Plasma Bombardment | Erupts Cr, Si, and Y atoms from targets for precise thin-film growth. |

| Vacuum Environment | Ensures high-purity composite reactions and dense film organization. |

| Film Structure | Produces uniform, high-density nanocomposite coatings with superior durability. |

Elevate Your Material Science with KINTEK Precision

High-performance CrSiN-Y coatings demand unparalleled control over vacuum integrity and plasma density. At KINTEK, we empower researchers and industrial manufacturers with cutting-edge Magnetron Sputtering and PVD systems tailored for complex nanocomposite fabrication.

Backed by expert R&D and world-class manufacturing, our customizable range includes Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet your unique lab and high-temperature furnace needs.

Ready to achieve superior coating uniformity and dense material organization?

Contact KINTEK Today to Consult with Our Experts

Visual Guide

References

- Lishan Dong, Zhifeng Wang. Porous High-Entropy Oxide Anode Materials for Li-Ion Batteries: Preparation, Characterization, and Applications. DOI: 10.3390/ma17071542

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

People Also Ask

- Why is high-purity argon necessary for PVC dechlorination? Ensure Precise Reaction Control & Safety

- Why is a fluidized bed reactor considered ideal for the co-gasification of biomass and non-biomass waste?

- What is the mechanism of the steam and air mixture used in the decoking process? Essential High-Temp Reaction Guide

- What is the objective of coordinating mechanical stirring and heating for perovskite slurries? Achieve Homogeneity

- What role does a laboratory oven play in W-doped TiO2? Ensure Precursor Stability for High-Purity Nanopowders

- How is a laboratory heat treatment furnace used for fluoride nanocrystal crystallization? Optimize Microstructure Control

- Why is substrate preheating typically employed during the LPBF process? Minimize Stress & Prevent Cracks in 3D Printing

- What is the role of a laboratory vacuum drying oven in LNMO electrode slurry preparation? Master Solvent Removal