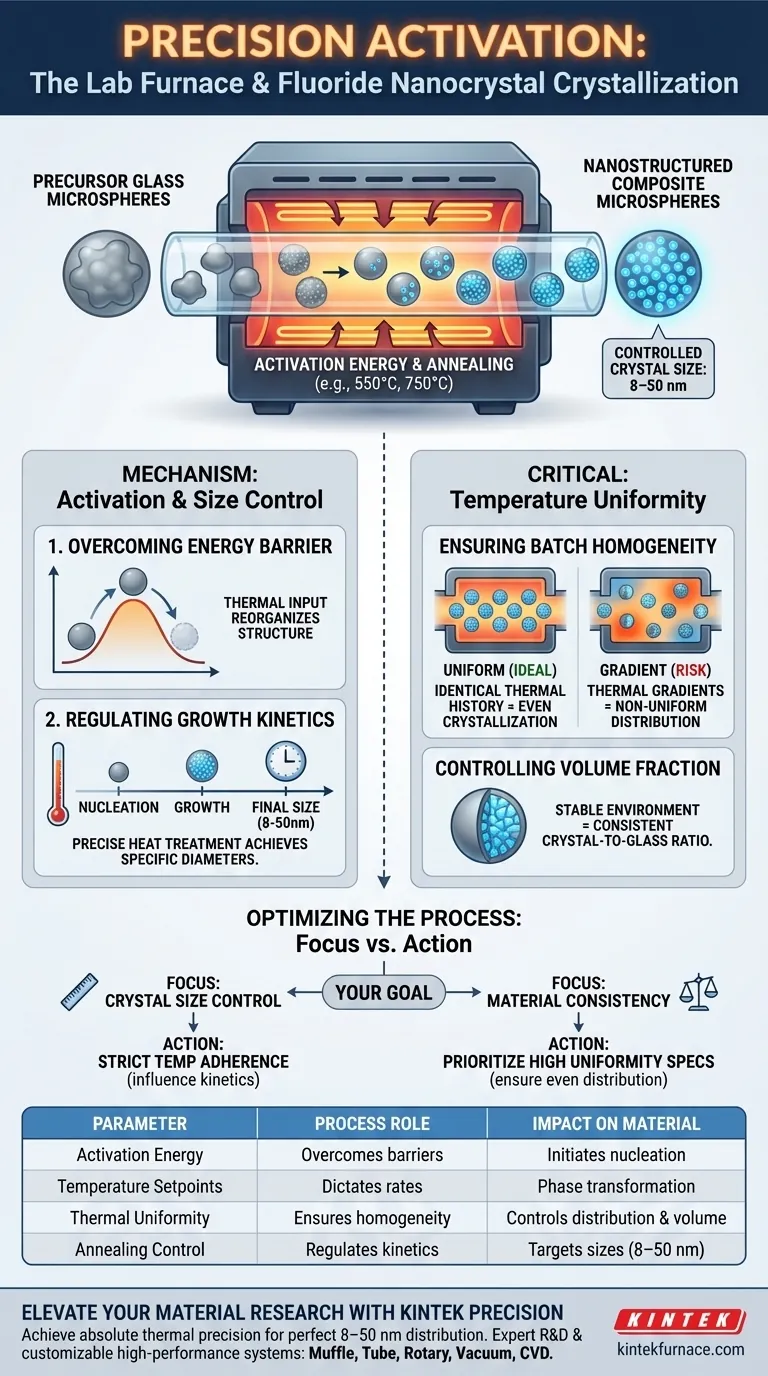

A laboratory heat treatment furnace serves as the precise activation chamber for transforming precursor glass microspheres into nanostructured materials. By maintaining exact constant-temperature environments—typically at set points such as 550°C or 750°C—the furnace supplies the necessary activation energy to trigger in-situ crystallization. This process converts the amorphous glass matrix into a composite structure embedded with fluoride nanocrystals.

The furnace is not merely a heater but a precision instrument that dictates material microstructure. Its ability to maintain strict thermal uniformity determines the volume, size, and distribution of nanocrystals, directly impacting the final optical and physical properties of the microspheres.

The Mechanism of In-Situ Crystallization

To understand the furnace's utility, one must look at how thermal energy drives the structural evolution of the glass.

Providing Activation Energy

The primary function of the furnace is to perform precise annealing.

By heating the precursor glass to specific temperatures, the furnace overcomes the thermodynamic energy barrier required for phase transformation.

This thermal input allows the glass structure to reorganize, initiating the nucleation process.

Regulating Crystal Size

The controlled environment is essential for managing the growth kinetics of the crystals.

Through regulated heat treatment, the process achieves specific nanocrystal diameters, typically ranging from 8 to 50 nm.

This size range is critical for maintaining the specific optical characteristics of the glass microspheres.

The Critical Role of Temperature Uniformity

While achieving the target temperature is necessary, how that temperature is distributed within the chamber is equally vital.

Ensuring Homogeneity

The temperature uniformity of the furnace chamber is the most significant variable in the process.

It ensures that every microsphere in the batch experiences the exact same thermal history.

Without this uniformity, crystallization would occur unevenly across the sample batch.

Controlling Volume Fraction

Precise heat distribution dictates the volume fraction of the crystals within the glass matrix.

A stable thermal environment ensures that the ratio of crystalline material to the remaining glass phase is consistent.

This consistency is required to produce microspheres with predictable performance characteristics.

Understanding the Trade-offs

Precise crystallization is a delicate balance, and equipment limitations can introduce significant errors.

The Risk of Thermal Gradients

If a furnace lacks high-grade temperature uniformity, it creates thermal gradients within the chamber.

This leads to a non-uniform distribution of nanocrystals, where some microspheres may be over-crystallized while others remain under-processed.

Such disparities result in a batch of microspheres with varying physical properties, rendering them unsuitable for high-precision applications.

Optimizing the Crystallization Process

To achieve the best results in your laboratory setting, consider how your specific goals align with furnace capabilities.

- If your primary focus is crystal size control: Strictly adhere to specific annealing temperatures (e.g., 550°C or 750°C) to influence growth kinetics and target the 8-50 nm range.

- If your primary focus is material consistency: Prioritize furnace specifications that guarantee high temperature uniformity to ensure an even distribution and volume fraction of nanocrystals.

Ultimately, the precision of your thermal equipment defines the structural integrity and uniformity of your final glass microspheres.

Summary Table:

| Parameter | Process Role | Impact on Material |

|---|---|---|

| Activation Energy | Overcomes thermodynamic barriers | Initiates nucleation in amorphous matrix |

| Temperature Setpoints | Typically 550°C to 750°C | Dictates phase transformation rates |

| Thermal Uniformity | Ensures batch homogeneity | Controls crystal distribution and volume fraction |

| Annealing Control | Regulates growth kinetics | Targets specific nanocrystal sizes (8–50 nm) |

Elevate Your Material Research with KINTEK Precision

Achieving the perfect 8–50 nm nanocrystal distribution requires more than just heat—it demands absolute thermal precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab requirements.

Whether you are refining fluoride nanocrystals or developing advanced nanostructured materials, our high-temperature furnaces provide the uniformity and control essential for predictable results. Contact us today to discuss your specific heat treatment needs and let our experts help you design the ideal furnace solution.

Visual Guide

References

- Zhigang Gao, Guoping Dong. Robust low threshold full-color upconversion lasing in rare-earth activated nanocrystal-in-glass microcavity. DOI: 10.1038/s41377-024-01671-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a high-precision furnace required for Li22Sn5 synthesis? Ensure Pure-Phase Alloy Stability

- How does the temperature of the annealing process specifically influence the luminescence properties of ZnSe? Guide

- What is the purpose of a high-temperature calcination furnace in Sol-Gel? Achieve High Purity and Crystallinity

- What are the advantages of using a multimode microwave applicator for alloy cladding? Rapid, Volumetric Internal Heat

- Why is a vacuum drying oven necessary for activated carbon? Ensure Accurate BET and Pore Size Analysis

- What is the purpose of treating EAF dust in a dryer? Ensure Precise Material Characterization & Data Integrity

- How does high-purity argon gas affect the production of ultrafine magnesium powder in evaporation-condensation methods? Master Particle Size Control

- What is shrinkage in the context of high-temperature materials? Master Dimensional Control for Stronger Parts