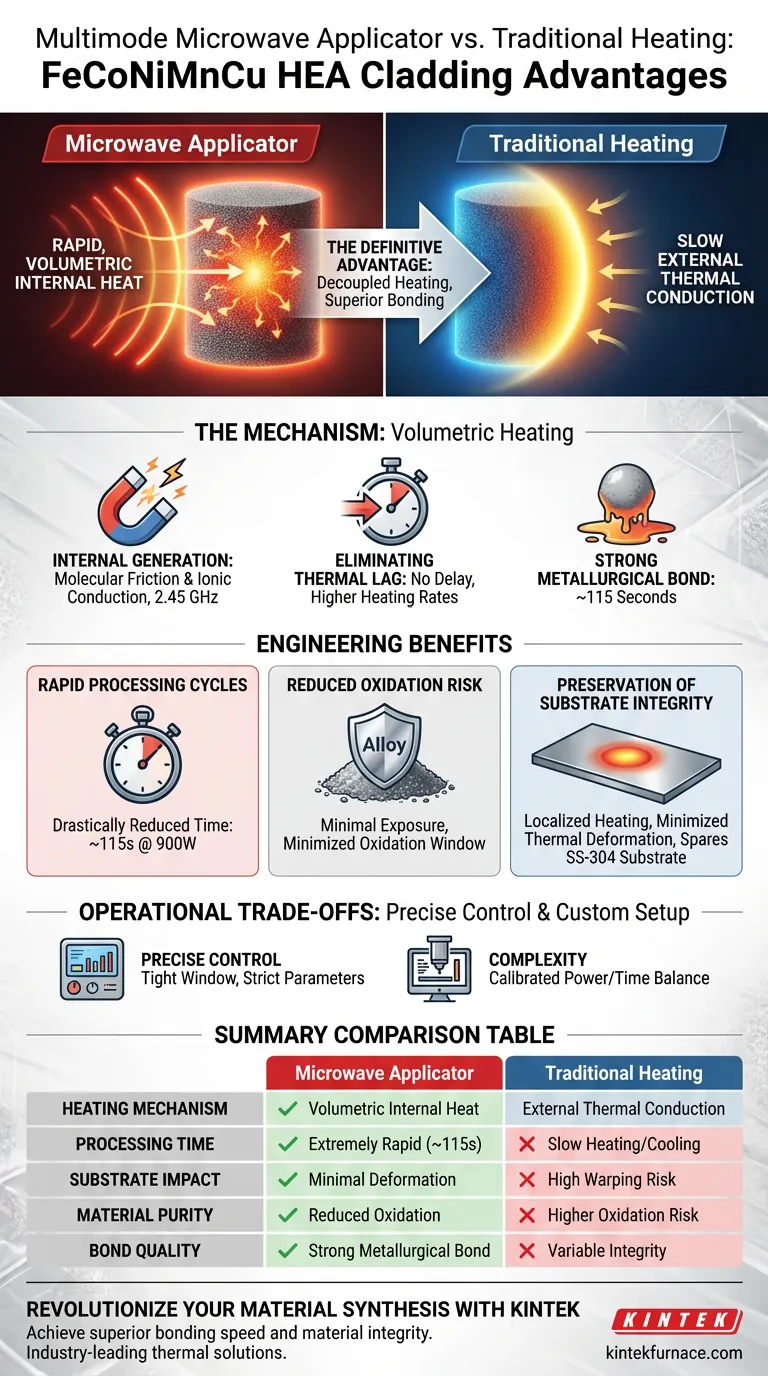

The definitive advantage of using a multimode microwave applicator is the generation of rapid, volumetric internal heat within the alloy material. Unlike traditional methods that rely on slow external thermal conduction, this technique utilizes electromagnetic waves to induce localized melting in the FeCoNiMnCu powder. This achieves a strong metallurgical bond in approximately 115 seconds while protecting the underlying substrate from excessive thermal deformation.

By shifting from external heat transfer to internal heat generation, microwave processing decouples the melting of the cladding from the heating of the substrate. This results in superior bonding speed and material integrity that traditional furnaces cannot match.

The Mechanism of Volumetric Heating

Internal Heat Generation

Traditional heating heats the outside of a material and waits for thermal energy to conduct inward. A multimode microwave applicator, operating at 2.45 GHz, reverses this process.

Molecular Friction and Ionic Conduction

The microwave energy acts directly on the High-Entropy Alloy (HEA) particles. Heat is generated internally through molecular friction and ionic conduction.

Eliminating Thermal Lag

Because the heat is generated within the material itself, there is no delay caused by thermal conductivity. This allows for significantly higher heating rates compared to conventional external heating sources.

Engineering Benefits for HEA Cladding

Rapid Processing Cycles

The efficiency of volumetric heating drastically reduces processing time. In this specific application, the cladding process requires only a short exposure duration of 115 seconds at 900W.

Reduced Oxidation Risk

Extended exposure to high temperatures in traditional furnaces often leads to material oxidation. The extreme speed of microwave heating significantly shortens the experimental cycle, thereby minimizing the window of opportunity for oxidation to occur.

Preservation of Substrate Integrity

A critical challenge in cladding is bonding the alloy without warping the base material. Microwave heating offers high selectivity, focusing energy on the powder.

Minimized Thermal Deformation

This localized heating ensures the FeCoNiMnCu powder melts to form a bond, but the SS-304 substrate is spared from prolonged thermal stress. This results in minimal overall deformation of the substrate.

Understanding the Operational Trade-offs

The Necessity of Precise Control

The speed of microwave heating is its greatest asset, but it also reduces the margin for error. With a processing window as tight as 115 seconds, parameters must be strictly controlled.

Complexity of Equipment

Unlike a standard furnace, these results rely on a "customized" applicator setup. Achieving the specific localized melting without overheating requires a calibrated balance of power (900W) and exposure time.

Making the Right Choice for Your Goal

While traditional heating is simple, microwave applicators offer precision and speed for advanced alloy synthesis.

- If your primary focus is Process Efficiency: Utilize microwave heating to reduce total processing times by potentially more than 90% compared to conventional thermal cycles.

- If your primary focus is Part Integrity: Choose this method to achieve a strong metallurgical bond while maintaining the dimensional accuracy of the substrate.

- If your primary focus is Material Purity: Leverage the rapid heating rates to reduce the risk of oxidation and avoid the need for expensive vacuum systems.

Microwave applicators transform cladding from a slow, thermal-stress-intensive process into a rapid, precise engineering solution.

Summary Table:

| Feature | Microwave Applicator (Multimode) | Traditional Heating Methods |

|---|---|---|

| Heating Mechanism | Volumetric internal heat (Molecular friction) | External thermal conduction |

| Processing Time | Extremely rapid (~115 seconds) | Slow heating/cooling cycles |

| Substrate Impact | Minimal thermal deformation; localized heating | High risk of warping/thermal stress |

| Material Purity | Reduced oxidation risk due to speed | Higher oxidation risk from long exposure |

| Bond Quality | Strong metallurgical bond | Variable bond integrity |

Revolutionize Your Material Synthesis with KINTEK

Are you looking to achieve superior bonding speed and material integrity for high-entropy alloys? KINTEK provides industry-leading thermal solutions backed by expert R&D and precision manufacturing.

Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature lab furnaces are fully customizable to meet your unique research and production needs. Enhance your laboratory's efficiency and preserve substrate integrity with our advanced heating technologies.

Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Shubham Sharma, Emad A. A. Ismail. Investigation of surface hardness, thermostability, tribo-corrosion, and microstructural morphological properties of microwave-synthesized high entropy alloy FeCoNiMnCu coating claddings on steel. DOI: 10.1038/s41598-024-55331-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What functions does glucose perform in lithium-ion sieve synthesis? Enhance Carbothermal Reduction for LiMnO2 Purity

- What role does an industrial-grade POCl3 diffusion furnace system play in DOSS? Master Quantitative Phosphorus Control

- Why is a vacuum desiccator essential for studying geopolymer porosity? Achieve Precise Material Characterization

- What are the structural advantages of specialized crystal growth furnaces for CZT? Achieve High-Purity Single Crystals

- What role does a laboratory vacuum drying oven play in preparing modified expanded graphite? Ensure Chemical Stability

- What is the difference between traditional metallurgical processes and powder metallurgy? Choose the Right Metal Process

- What are the typical functions performed by laboratory furnaces? Unlock Precise Thermal Processing for Your Materials

- What is the primary function of a high-temperature electric furnace during solution treatment? Achieve Alloy Homogeneity