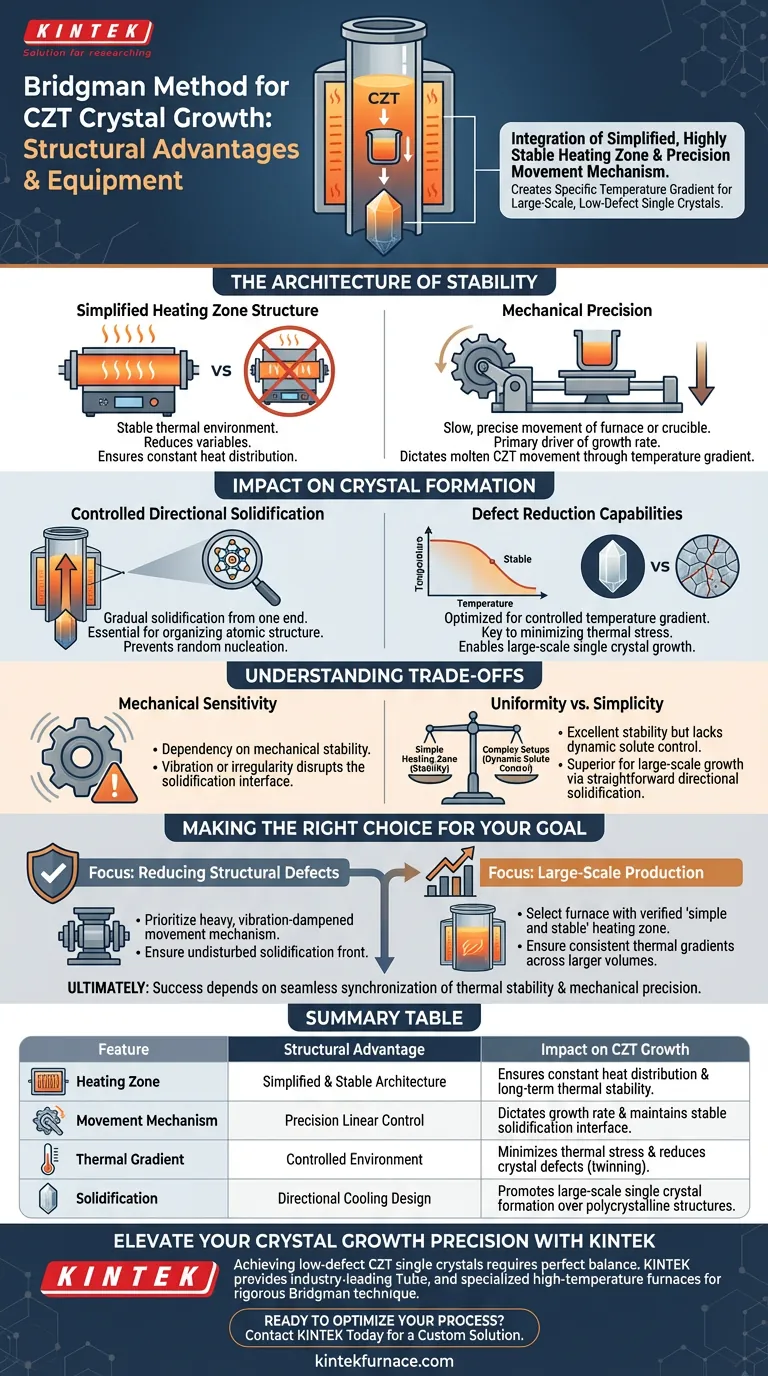

The primary structural advantage of specialized crystal growth furnaces used for the Bridgman Method lies in the integration of a simplified, highly stable heating zone with a precision movement mechanism. These furnaces rely on a fundamental design architecture that prioritizes thermal stability and mechanical control to manage the solidification interface.

By maintaining a stable heating zone and precisely controlling the relative motion of the furnace or crucible, this equipment creates the specific temperature gradient required to transform polycrystalline raw materials into large-scale, low-defect single crystals.

The Architecture of Stability

Simplified Heating Zone Structure

Unlike more complex growth methods that require intricate multi-zone modulation, Bridgman furnaces utilize a simple and stable heating zone. This structural simplicity reduces the number of variables affecting the thermal environment. It ensures that the heat distribution remains constant throughout the long duration of the growth cycle.

Mechanical Precision

The structural design incorporates a mechanism for the slow, precise movement of either the furnace body or the crucible itself. This mechanical feature is not merely for transport; it is the primary driver of the growth rate. It dictates exactly how fast the molten Cadmium Zinc Telluride (CZT) moves through the temperature gradient.

Impact on Crystal Formation

Controlled Directional Solidification

The interaction between the stable heating structure and the moving component forces the raw material to solidify gradually from one end. This directional cooling is essential for organizing the atomic structure of the crystal. It prevents the random nucleation that characterizes polycrystalline materials.

Defect Reduction Capabilities

The equipment is structurally optimized to maintain a controlled temperature gradient environment. This specific physical condition is the key factor in minimizing thermal stress during solidification. By stabilizing this gradient, the furnace structure directly contributes to reducing crystal defects and enabling the growth of large-scale single crystals.

Understanding the Trade-offs

Mechanical Sensitivity

While the heating structure is simple, the reliance on physical movement introduces a dependency on mechanical stability. Any vibration or irregularity in the movement mechanism (of the crucible or furnace body) can disrupt the solidification interface.

Uniformity vs. Simplicity

The Bridgman furnace's simple heating zone is excellent for stability, but it may lack the dynamic solute control found in more complex setups like the Traveling Heater Method (THM). While Bridgman is superior for creating large-scale crystals via straightforward directional solidification, it relies heavily on the initial quality of the polycrystalline raw material.

Making the Right Choice for Your Goal

To maximize the effectiveness of the Bridgman Method for CZT growth, align your equipment choice with your specific quality targets.

- If your primary focus is reducing structural defects: Prioritize a furnace design with a heavy, vibration-dampened movement mechanism to ensure the solidification front remains undisturbed.

- If your primary focus is large-scale production: Select a furnace with a verified "simple and stable" heating zone architecture to ensure consistent thermal gradients across larger volumes.

Ultimately, the success of the Bridgman Method depends not on thermal complexity, but on the seamless synchronization of thermal stability and mechanical precision.

Summary Table:

| Feature | Structural Advantage | Impact on CZT Growth |

|---|---|---|

| Heating Zone | Simplified & Stable Architecture | Ensures constant heat distribution and long-term thermal stability. |

| Movement Mechanism | Precision Linear Control | Dictates growth rate and maintains a stable solidification interface. |

| Thermal Gradient | Controlled Environment | Minimizes thermal stress and reduces crystal defects like twinning. |

| Solidification | Directional Cooling Design | Promotes large-scale single crystal formation over polycrystalline structures. |

Elevate Your Crystal Growth Precision with KINTEK

Achieving low-defect CZT single crystals requires a perfect balance of thermal stability and mechanical control. KINTEK provides industry-leading Tube and specialized high-temperature furnaces designed specifically for rigorous growth methods like the Bridgman technique.

Backed by expert R&D and precision manufacturing, our systems offer the vibration-dampened movement and stable thermal gradients necessary to maximize your yield. Whether you need standard or fully customizable vacuum and CVD systems, KINTEK empowers your lab with the tools for excellence.

Ready to optimize your directional solidification process? Contact KINTEK today for a custom solution.

Visual Guide

References

- Z. J. Li, Zeqian Wu. Research on the Technological Progress of CZT Array Detectors. DOI: 10.3390/s24030725

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is industrial-grade isostatic pressing necessary for zirconia? Achieve Uniform Density & Structural Integrity

- Why is a pre-melting process required in phase equilibrium studies? Reset Your Sample for Precise Results

- Why is a vacuum drying oven required for processing MXene solutions and NPC@MoS2 nanostructures? Key Benefits Revealed

- Why is a high-precision programmed heating furnace essential for the annealing reduction of intermetallic compounds?

- Why is an air-ventilated oven necessary for GFPP surface modification? Achieve Maximum Solar Reflectance

- How does a high vacuum deposition system ensure thin film quality? Purity Through Advanced Pumping

- What is the role of homogeneous catalysts such as Na2CO3 or KOH in HTL? Boost Bio-crude Yield & Quality

- How do you maintain vacuum pressure? Master the Balance of Gas Load & Pumping Speed