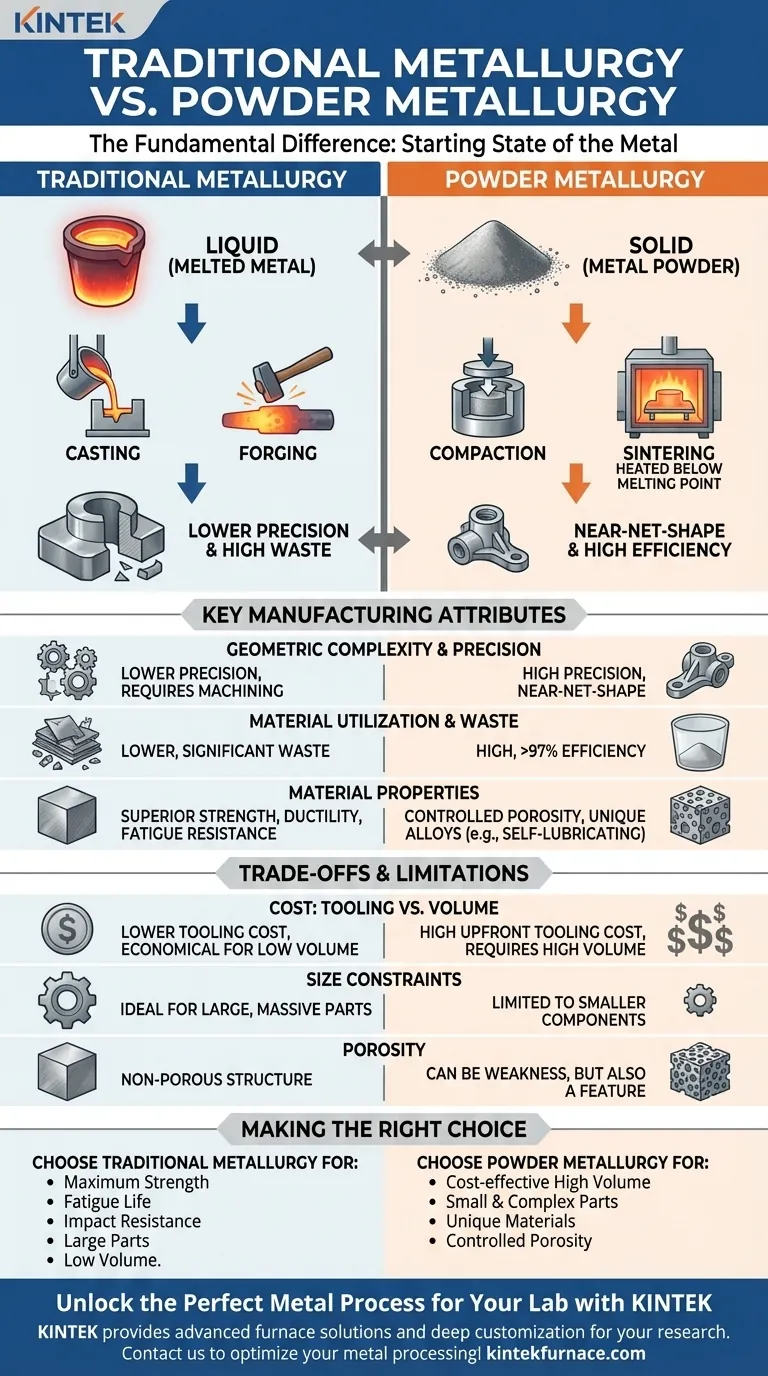

The fundamental difference between traditional metallurgy and powder metallurgy lies in the starting state of the metal. Traditional processes like casting or forging begin by completely melting metal into a liquid state, which is then solidified into its final shape. In contrast, powder metallurgy is a "solid-state" process that builds parts by compacting metallic powders and then heating them to bond the particles together without ever reaching a fully liquid phase.

The choice between these two families of processes is not a matter of which is superior, but a strategic decision based on the required part complexity, production volume, material properties, and overall cost. Each path offers a distinct set of advantages and limitations.

A Tale of Two States: Liquid vs. Powder

The initial state of the material dictates every subsequent step of the manufacturing process, influencing everything from tooling and energy consumption to the final microstructure of the component.

The Traditional Path: Casting and Forging

Traditional metallurgy is a "top-down" approach. You start with a large mass of solid metal (ingots, billets), melt it down completely, and then form it.

The most common methods are casting, where molten metal is poured into a mold, and forging, where a solid billet is heated and shaped by compressive force.

These processes are ideal for creating large, structurally simple parts and have been the bedrock of metalworking for centuries, producing everything from engine blocks to structural beams.

The Powder Metallurgy Path: Compacting and Sintering

Powder metallurgy (PM) is a "bottom-up" approach. It begins with a precisely engineered metallic powder.

The process involves two primary stages: compaction, where the powder is pressed into the desired shape in a die, and sintering, where this "green compact" is heated in a controlled-atmosphere furnace.

This heating occurs below the metal's melting point, causing the individual powder particles to fuse and densify, forming a solid part.

Comparing Key Manufacturing Attributes

The decision to use a traditional process or powder metallurgy hinges on a few critical engineering and economic factors.

Geometric Complexity and Precision

Powder metallurgy excels at producing small, intricate, and dimensionally consistent parts directly from the tool. This is known as near-net-shape manufacturing.

This high precision drastically reduces or eliminates the need for costly secondary machining operations.

Traditional casting can also create complex shapes, but often with less precision, requiring more significant machining to meet final tolerances. Forged parts often have simpler geometries and require machining.

Material Utilization and Waste

Powder metallurgy is an exceptionally efficient process, often utilizing over 97% of the starting material. The powder that doesn't go into a part is easily recycled back into the process.

Traditional subtractive manufacturing, where a part is machined from a larger block of metal, can generate significant waste in the form of chips and scrap.

Material Properties and Performance

Forged and wrought metals typically exhibit superior tensile strength, ductility, and fatigue resistance due to their dense, non-porous grain structure.

Powder metallurgy parts inherently contain some level of porosity. While this can be a disadvantage for strength, it can also be a design feature, used to create self-lubricating bearings by impregnating the pores with oil.

Furthermore, PM allows for the creation of unique material systems like metal matrix composites (MMCs) and refractory metal alloys (like tungsten) that are impossible to produce through melting.

Understanding the Trade-offs and Limitations

No process is without its drawbacks. An objective evaluation requires acknowledging the limitations of each approach.

The Cost Equation: Tooling vs. Volume

Powder metallurgy involves very high upfront costs for the hardened steel or carbide dies used for compaction. This investment is only justified for high-volume production runs, typically in the tens or hundreds of thousands of parts.

For low-volume production or prototypes, the lower tooling costs associated with traditional casting or machining from billet are far more economical.

Size and Shape Constraints

PM is generally limited to producing relatively small components. The immense pressures required to compact the powder uniformly become impractical for very large parts.

Traditional casting, by contrast, can produce massive components weighing many tons, such as ship propellers or turbine housings.

Porosity: A Double-Edged Sword

The residual porosity in standard PM parts is often their primary mechanical weakness, acting as an initiation point for cracks under stress.

While secondary operations like hot isostatic pressing (HIP) can be used to create fully dense PM parts with excellent properties, this adds significant cost and complexity to the process.

Making the Right Choice for Your Application

The optimal process is the one that best serves your project's unique constraints and performance goals.

- If your primary focus is cost-effective, high-volume production of small, complex parts with good dimensional accuracy: Powder metallurgy is almost always the superior choice.

- If your primary focus is maximum mechanical strength, fatigue life, and impact resistance for a critical component: Traditional forging is the industry standard for performance.

- If your primary focus is creating parts from unique material blends or designing for controlled porosity (e.g., filters or self-lubrication): Powder metallurgy is the only viable manufacturing path.

Understanding these core differences empowers you to select a manufacturing process that aligns perfectly with your component's design, performance, and economic requirements.

Summary Table:

| Attribute | Traditional Metallurgy | Powder Metallurgy |

|---|---|---|

| Starting State | Liquid (melted metal) | Solid (metal powder) |

| Key Processes | Casting, forging | Compaction, sintering |

| Geometric Complexity | Lower precision, often requires machining | High precision, near-net-shape |

| Material Utilization | Lower, more waste | High, over 97% efficiency |

| Material Properties | Superior strength, ductility | Controlled porosity, unique alloys |

| Ideal Use Cases | Large parts, high strength | Small, complex parts, high volume |

Unlock the Perfect Metal Process for Your Lab with KINTEK

Struggling to choose between traditional metallurgy and powder metallurgy for your experiments? KINTEK is here to help! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Whether you need precise temperature control for sintering or robust systems for traditional processes, we deliver reliable, tailored solutions that enhance efficiency and accuracy.

Contact us today via our contact form to discuss how our furnaces can optimize your metal processing and drive your research forward!

Visual Guide

Related Products

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Spark Plasma Sintering SPS Furnace

People Also Ask

- How does the hot pressing mechanism enhance TiB2-TiN density? Achieve Superior Hardness in Tool Materials

- What is the core processing value of a vacuum hot pressing sintering furnace? Master AZ31 Magnesium Alloy Density

- How does the programmable pressure function of a vacuum hot press furnace influence the quality of IZO targets?

- What is the function of applying axial pressure during hot press sintering? Achieve High-Density Metal Composites

- Why is multi-stage pressure regulation required in a vacuum hot press furnace? Optimize Ti-Al3Ti Composite Sintering