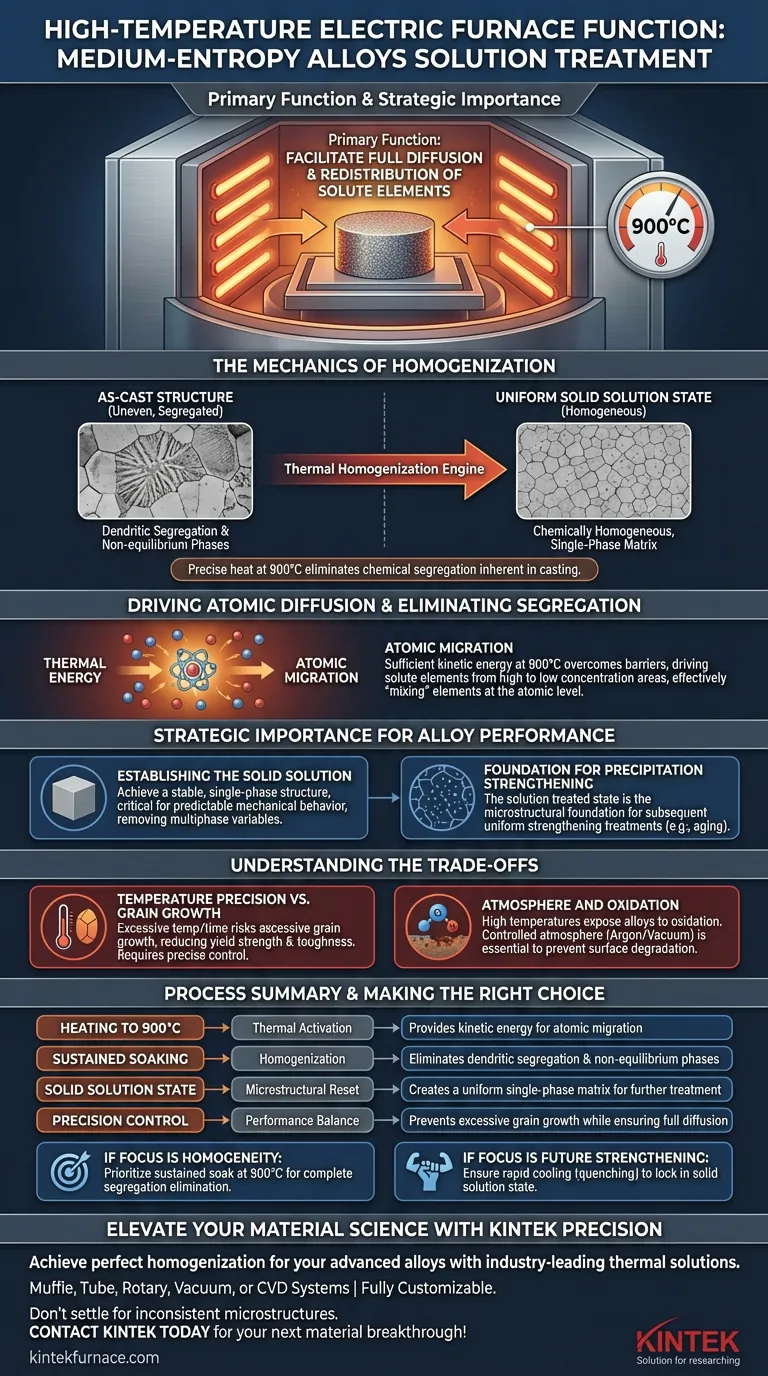

The primary function of a high-temperature electric furnace during the solution treatment of medium-entropy alloys is to facilitate the full diffusion and redistribution of solute elements. By heating the alloy to a specific temperature, typically 900°C, and maintaining it for a set duration, the furnace converts the uneven as-cast structure into a uniform solid solution state.

Core Takeaway The furnace acts as a thermal homogenization engine, using precise heat to eliminate chemical segregation inherent in casting. This process creates a uniform microstructural baseline, which is the absolute prerequisite for any subsequent hardening or strengthening treatments.

The Mechanics of Homogenization

Driving Atomic Diffusion

The furnace provides the thermal energy necessary to mobilize atoms within the alloy's lattice structure. At 900°C, the kinetic energy is sufficient to overcome the energy barriers that usually keep atoms stationary.

This thermal input drives solute elements to migrate from areas of high concentration to areas of low concentration. It is the physical mechanism that effectively "mixes" the metallic elements at the atomic level.

Eliminating Compositional Segregation

During the initial casting process, alloys often develop dendritic segregation, where chemical composition varies significantly between the center of a grain and its edge. The electric furnace serves to erase these inconsistencies.

By maintaining a constant temperature for a sustained period (e.g., one hour), the furnace ensures that non-equilibrium phases are dissolved. This results in a chemically homogeneous material where every section of the alloy possesses the same elemental makeup.

Strategic Importance for Alloy Performance

Establishing the Solid Solution

The immediate goal of this thermal cycle is to achieve a uniform solid solution state. This means the alloying elements are fully dissolved into the matrix phase, much like sugar fully dissolving into hot water.

A stable, single-phase structure is critical for predicting how the material will behave mechanically. It removes the variables caused by multiphase structures that can interfere with oxidation behavior or ductility.

The Foundation for Precipitation Strengthening

While solution treatment homogenizes the alloy, its ultimate value lies in what comes next: precipitation strengthening. The primary reference identifies the solution treated state as the "microstructural foundation" for this process.

If the elements are not evenly distributed first, subsequent treatments to increase hardness (such as aging at 500°C) will result in uneven strength and potential failure points. The solution treatment ensures that future strengthening phases precipitate uniformly throughout the material.

Understanding the Trade-offs

Temperature Precision vs. Grain Growth

While high temperatures facilitate diffusion, there is a strict upper limit. If the temperature exceeds the optimal window or the holding time is too long, the alloy risks excessive grain growth.

Large grains can reduce the material's yield strength and toughness. Therefore, the furnace must offer precise control to balance thorough diffusion against the degradation of mechanical properties.

Atmosphere and Oxidation

High-temperature treatment exposes the alloy to the risk of surface oxidation, particularly for alloys containing active elements like Titanium or Aluminum.

While the furnace provides the heat, it must often be paired with a controlled atmosphere (such as Argon or Vacuum). Without this protection, the benefits of homogenization can be negated by surface degradation or element loss.

Making the Right Choice for Your Goal

To maximize the utility of solution treatment for medium-entropy alloys, align your process parameters with your specific material objectives.

- If your primary focus is Homogeneity: Prioritize a stable, sustained soak at 900°C to ensure complete elimination of dendritic segregation from the casting process.

- If your primary focus is Future Strengthening: Ensure the cooling rate following the furnace soak is rapid (quenching) to lock in the solid solution state before precipitation treatments begin.

The electric furnace is not just a heating element; it is the tool that resets the material's history to ensure consistent, high-performance results.

Summary Table:

| Process Step | Primary Function | Technical Mechanism |

|---|---|---|

| Heating to 900°C | Thermal Activation | Provides kinetic energy for atomic migration |

| Sustained Soaking | Homogenization | Eliminates dendritic segregation and non-equilibrium phases |

| Solid Solution State | Microstructural Reset | Creates a uniform single-phase matrix for further treatment |

| Precision Control | Performance Balance | Prevents excessive grain growth while ensuring full diffusion |

Elevate Your Material Science with KINTEK Precision

Ready to achieve perfect homogenization for your advanced alloys? KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temp lab furnaces are fully customizable to meet your unique medium-entropy alloy processing needs.

Don't settle for inconsistent microstructures. Contact KINTEK today to discover how our precision heating technology can serve as the foundation for your next material breakthrough!

Visual Guide

References

- Denis Ariel Ávila-Salgado, José Luis Camacho-Martínez. Evolution of Microstructure, Hardness, and Wear Behavior of Medium-Entropy CuNiSiCrCoTiNbx Alloy. DOI: 10.3390/lubricants13040164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a benchtop industrial oven improve efficiency? Boost Energy Savings and Space Use

- How does the SCRS model simplify furnace combustion simulation? Efficiency Meets Accuracy in Thermal Modeling

- How does a temperature-programmed system influence molybdenum carbide formation? Expert Catalyst Synthesis Guide

- What is the purpose of using a laboratory drying oven for catalyst recycling? Optimize Performance & Data Integrity

- What is the function of a Teflon-lined autoclave in hydrothermal acid treatment? Enhance Catalyst Synthesis Efficiency

- What process problems are addressed by using a walking-beam furnace model? Solve Clad Plate Thermal Stress Challenges

- How does temperature control precision affect SC-NMNO crystal morphology? Master Thermal Fields for High-Quality Grains

- How do thermal systems reveal anti-spalling mechanisms in CDE concrete? Explore Advanced Material Resilience