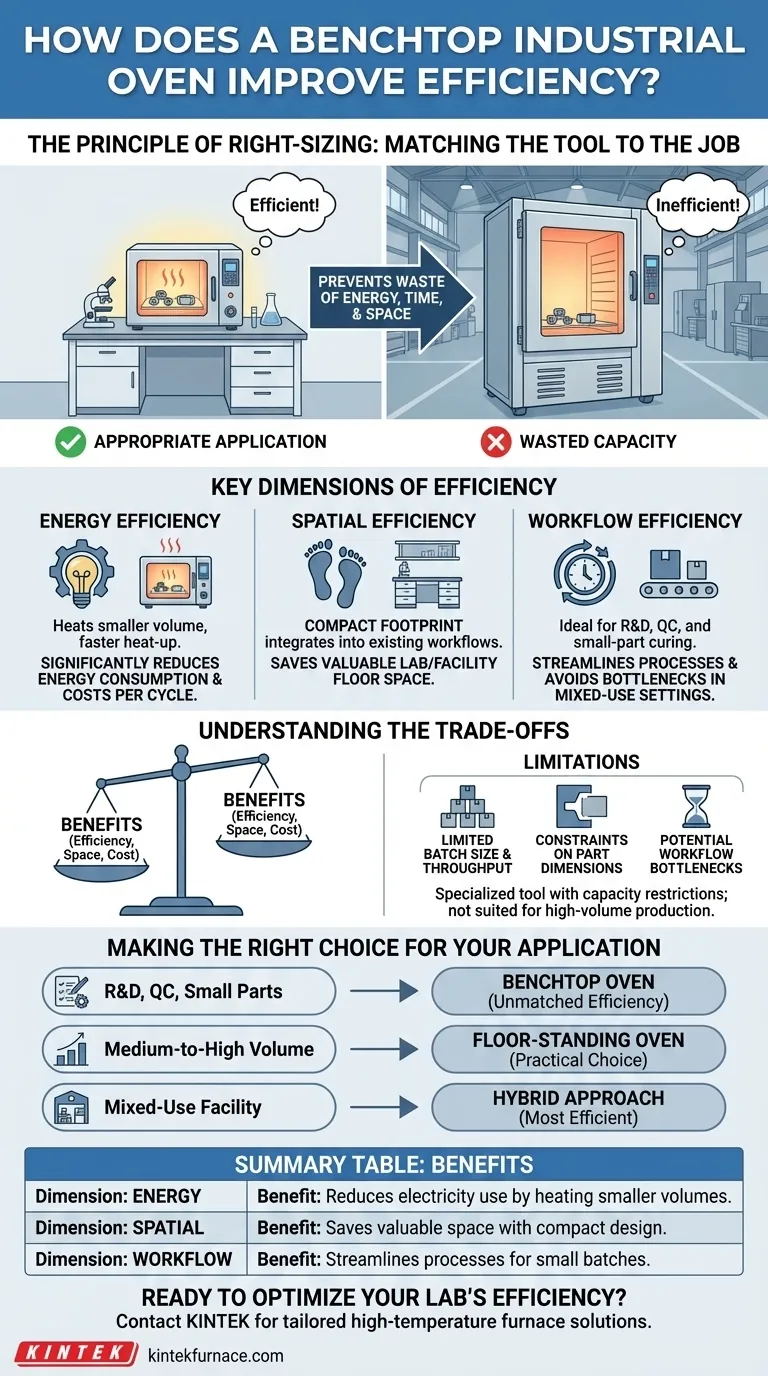

At its core, a benchtop industrial oven improves efficiency by precisely matching the equipment's scale to the task at hand. Instead of using a large, energy-intensive floor model for a small number of parts, a benchtop unit heats a smaller volume, drastically reducing energy consumption and freeing up valuable laboratory or facility space.

The true efficiency of a benchtop oven is not in its absolute power, but in its appropriate application. It prevents the waste of energy, time, and space that occurs when oversized equipment is used for small-scale heat-treatment tasks.

The Principle of Right-Sizing

The decision to use a benchtop oven is rooted in a fundamental industrial principle: matching the tool to the job. Using an oversized oven for a small batch is like using a cargo truck to deliver a single letter—it works, but it's profoundly inefficient.

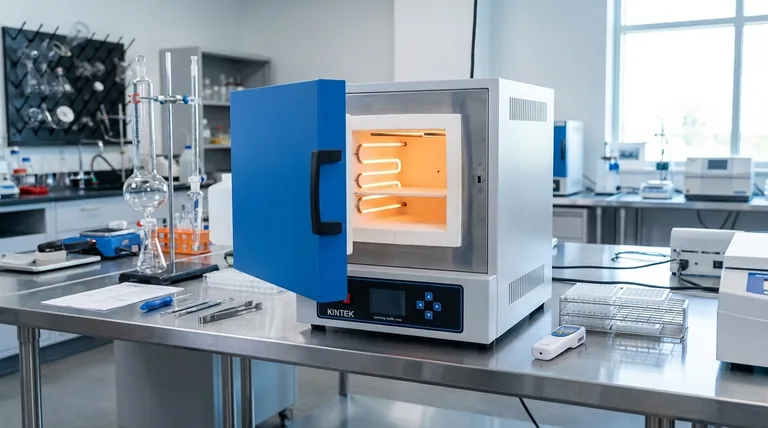

What Defines a Benchtop Oven?

A benchtop industrial oven is a compact, self-contained unit designed to be placed on a standard workbench or countertop. Its defining characteristic is its small footprint compared to larger, upright or walk-in ovens.

The Hidden Costs of Unused Capacity

Every time a large industrial oven is heated, you pay to bring its entire internal volume and structure up to temperature. When processing only a few small samples, the vast majority of that energy is spent heating empty air, not your parts.

Key Dimensions of Efficiency

Efficiency in this context is not a single metric. It is a combination of energy savings, space conservation, and streamlined workflow.

Energy Efficiency for Small Batches

The primary efficiency gain comes from energy conservation. A smaller chamber requires significantly less energy to reach and maintain a target temperature.

For applications like quality control, research and development, or small-part curing, a benchtop oven heats only the necessary volume. This results in faster heat-up times and lower electricity costs per cycle.

Spatial Efficiency in the Lab

In any technical facility, floor and bench space is a premium asset. A large oven can occupy a significant footprint that could otherwise be used for other critical processes or equipment.

A benchtop model's compact size allows it to integrate into existing workflows without requiring a major facility layout change, making it ideal for smaller labs or crowded production floors.

Understanding the Trade-offs

A benchtop oven is a specialized tool, and its efficiency is directly tied to its limitations. Understanding these trade-offs is critical for making an informed decision.

Limited Batch Size and Throughput

The most obvious trade-off is capacity. These ovens are fundamentally unsuited for high-volume production. Their small chamber restricts the number of parts that can be processed at one time.

Constraints on Part Dimensions

The physical size of the oven chamber naturally limits the dimensions of the parts you can heat-treat. Large or irregularly shaped components will simply not fit, requiring a larger floor model regardless of batch size.

Potential Workflow Bottlenecks

If your process demand grows unexpectedly, a benchtop oven can quickly become a bottleneck. Relying on a small unit for a task that has outgrown its capacity will slow down your entire workflow.

Making the Right Choice for Your Application

Selecting the correct oven requires an objective assessment of your operational needs, not just the specifications of the equipment.

- If your primary focus is R&D, quality testing, or processing small, individual parts: A benchtop oven provides unmatched efficiency by minimizing energy and space waste.

- If your primary focus is medium-to-high volume production: A larger, floor-standing oven is the only practical choice to meet throughput requirements.

- If you run a mixed-use facility with both production and small-batch needs: The most efficient solution is often a hybrid approach, using a benchtop unit for urgent or small jobs to keep the larger production oven free.

Ultimately, choosing the right oven is about aligning the equipment's scale with your operational reality.

Summary Table:

| Dimension of Efficiency | Key Benefit |

|---|---|

| Energy Efficiency | Reduces electricity use by heating smaller volumes, lowering costs per cycle |

| Spatial Efficiency | Saves valuable lab or facility space with a compact, benchtop design |

| Workflow Efficiency | Streamlines processes for small batches, avoiding bottlenecks in mixed-use settings |

Ready to optimize your lab's efficiency with the right benchtop oven? At KINTEK, we specialize in high-temperature furnace solutions tailored to your needs. Leveraging our exceptional R&D and in-house manufacturing, we offer advanced products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we ensure precise alignment with your unique experimental requirements. Contact us today via our contact form to discuss how we can enhance your laboratory's performance and efficiency!

Visual Guide

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role do high-precision laboratory ovens play in assessing the energy potential of MSW? Enhancing Biomass Accuracy

- How are a muffle furnace and ceramic crucible used for MoO3? Master High-Purity Synthesis Today

- Why is it necessary to dry glassware in a 140 °C oven overnight before GTP? Ensure Precise Anhydrous Polymerization

- How does a box-type high-temperature furnace contribute to 6Mo stainless steel? Optimize Solution Treatment Now

- Why is dual heat treatment required for SnO2 nanoparticles? Optimize Oxidation for Superior Performance