Precise thermal regulation is the defining contribution of a box-type high-temperature furnace during the solution treatment of 6Mo super-austenitic stainless steel. By maintaining a stable environment between 1100°C and 1250°C, this equipment ensures the complete dissolution of alloying elements and the elimination of harmful secondary phases.

The box-type furnace acts as a critical homogenization tool, leveraging specific temperature plateaus to dissolve Chromium and Molybdenum into the austenite matrix. This process directly dictates the material's final pitting corrosion resistance by optimizing grain size and suppressing deleterious precipitates.

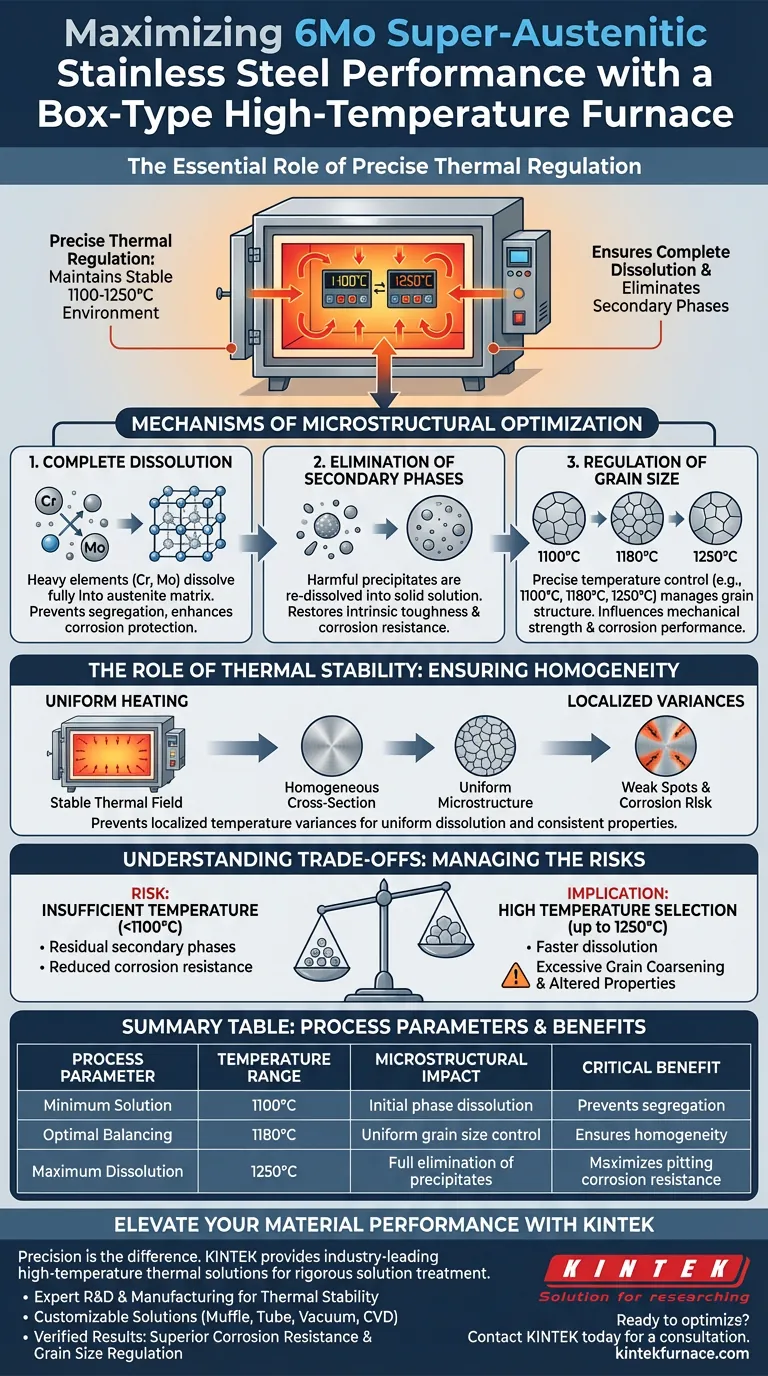

Mechanisms of Microstructural Optimization

The primary function of the furnace is not merely heating the metal, but orchestrating a complex phase transformation that defines the steel's capabilities.

Complete Dissolution of Alloying Elements

6Mo stainless steel relies heavily on high concentrations of Chromium and Molybdenum for its superior properties.

The box-type furnace provides the necessary thermal energy to force these heavy alloying elements to dissolve fully into the austenite matrix. Without this stable high-temperature environment, these elements would remain segregated, failing to provide the intended corrosion protection.

Elimination of Secondary Phases

During processing, harmful secondary phases often precipitate, which can compromise the material's integrity.

The furnace facilitates a solution treatment process that re-dissolves these precipitated phases back into the solid solution. This "cleansing" of the microstructure is essential for restoring the intrinsic toughness and corrosion resistance of the super-austenitic alloy.

Regulation of Grain Size

Temperature control within the furnace allows for the precise manipulation of the material's grain structure.

By targeting specific set points—such as 1100°C, 1180°C, or 1250°C—operators can regulate the final grain size. This control is vital, as grain size directly influences both the mechanical strength and the corrosion performance of the final product.

The Role of Thermal Stability

While the primary reference highlights temperature targets, the "box-type" configuration is significant for the stability it offers.

Ensuring Homogeneity

Similar to processes used for high-performance alloys like TWIP steel, a stable thermal field is required to eliminate compositional segregation.

The box-type furnace offers a uniform heating chamber that prevents localized temperature variances. This ensures that the dissolution of secondary phases occurs uniformly throughout the cross-section of the steel, preventing weak spots where corrosion could initiate.

Understanding the Trade-offs

Achieving the correct solution treatment is a balancing act. The box-type furnace is the tool used to manage these critical trade-offs.

The Risk of Insufficient Temperature

If the furnace fails to maintain the minimum required temperature (e.g., dipping below 1100°C), dissolution will be incomplete.

This results in residual secondary phases and undissolved alloying elements. The immediate consequence is a significant reduction in pitting corrosion resistance, rendering the "super" properties of the steel ineffective.

The Implications of Temperature Selection

While higher temperatures facilitate faster dissolution, they also impact grain growth.

Operating at the upper limit (1250°C) ensures maximum dissolution of stubborn phases but necessitates careful monitoring to prevent excessive grain coarsening, which can alter mechanical properties.

Making the Right Choice for Your Goal

The effectiveness of your solution treatment depends on how precisely you utilize the furnace's capabilities.

- If your primary focus is maximizing Pitting Corrosion Resistance: Ensure the furnace is set to a temperature high enough (typically toward 1250°C) to guarantee the total elimination of all secondary precipitated phases.

- If your primary focus is Microstructural Homogeneity: prioritize the stability of the furnace to maintain a precise set point (e.g., 1180°C) that balances complete dissolution with controlled grain size.

Ultimately, the box-type high-temperature furnace is the gatekeeper of quality, transforming raw alloy potential into verified industrial performance.

Summary Table:

| Process Parameter | Temperature Range | Microstructural Impact | Critical Benefit |

|---|---|---|---|

| Minimum Solution | 1100°C | Initial phase dissolution | Prevents alloying element segregation |

| Optimal Balancing | 1180°C | Uniform grain size control | Ensures microstructural homogeneity |

| Maximum Dissolution | 1250°C | Full elimination of precipitates | Maximizes pitting corrosion resistance |

Elevate Your Material Performance with KINTEK

Precision is the difference between standard alloy and super-austenitic excellence. KINTEK provides industry-leading high-temperature thermal solutions designed for the rigorous demands of solution treatment.

Why partner with KINTEK?

- Expert R&D & Manufacturing: Our systems are engineered for the thermal stability required to eliminate harmful secondary phases.

- Customizable Solutions: From Muffle and Tube furnaces to specialized Vacuum and CVD systems, we tailor every unit to your specific metallurgical goals.

- Verified Results: Achieve superior pitting corrosion resistance and precise grain size regulation with our advanced temperature control technology.

Ready to optimize your 6Mo stainless steel processing? Contact KINTEK today for a consultation and let our lab experts design the perfect furnace for your unique needs.

Visual Guide

References

- Haiyu Tian, Peide Han. Effect of Nitrogen on the Corrosion Resistance of 6Mo Super Austenitic Stainless Steel. DOI: 10.3390/met14040391

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What should be done if the silicon carbon rod in the muffle furnace ages? Restore Performance with Expert Tips

- Industrial Applications of High-Temperature Furnaces for Biochar Analysis: Precision Control & Efficiency

- Why must ceramic tubes coated with gas-sensing layers undergo annealing in a muffle furnace? Unlock Sensor Stability

- How long does it take for a muffle furnace to reach maximum temperature? Optimize Your Lab's Heating Efficiency

- Why is a high-temperature muffle furnace required for the secondary calcination of SC-NMNO? Key to Single Crystals

- How are box type electric furnaces utilized in laboratory research? Enhance Precision in Material Synthesis and Testing

- What was the initial purpose of a muffle furnace and how has it evolved? Discover Its Journey from Contamination Shield to Precision Tool

- What role do auxiliary equipment like fans and sprayers play in a box furnace? Enhance Precision and Efficiency in Heat Treatment