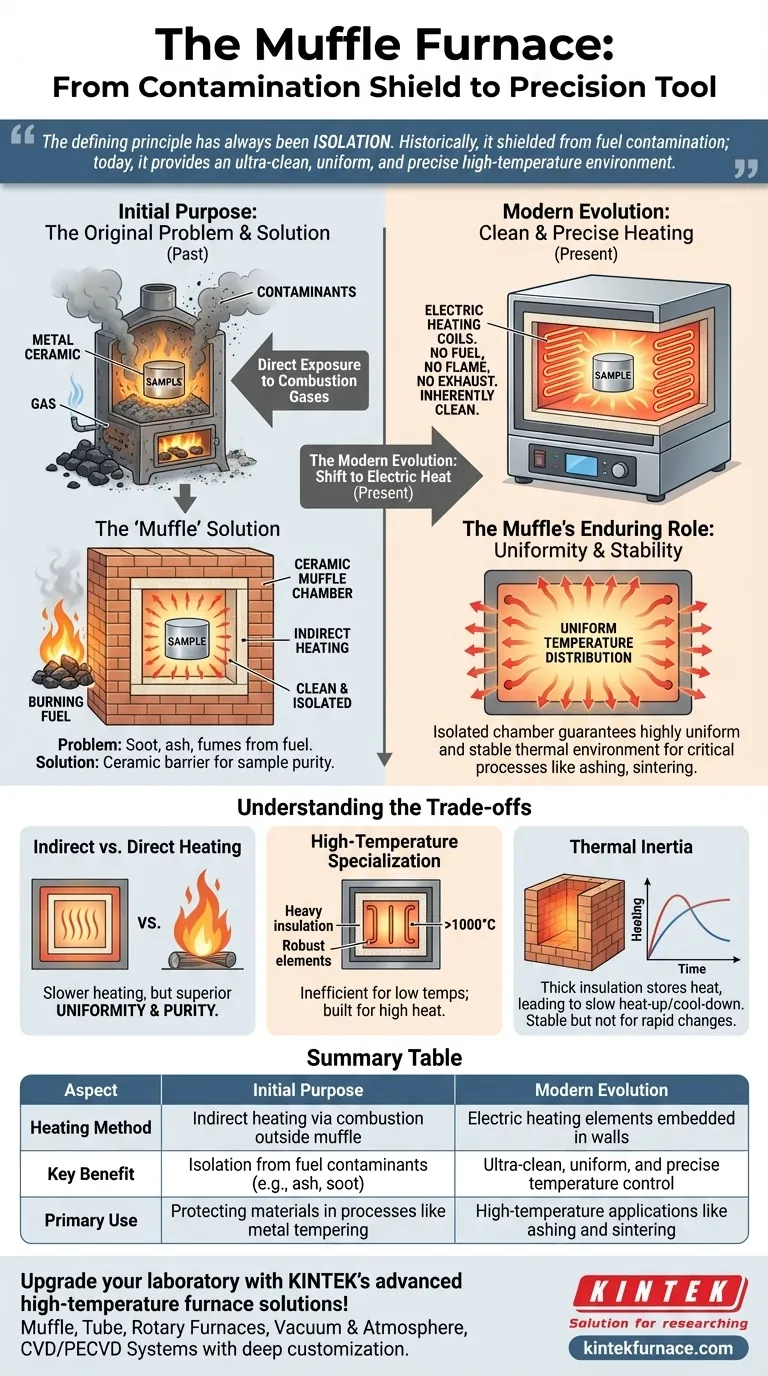

At its core, a muffle furnace was originally designed to solve a single, critical problem: contamination. Its initial purpose was to isolate a sample from the harmful byproducts of a fuel-based heat source, such as ash, soot, and chemical fumes. While the heat source has evolved from combustion to electricity, this fundamental principle of creating a clean, isolated heating environment remains the furnace's defining characteristic.

The defining principle of a muffle furnace has always been isolation. Historically, it shielded materials from fuel contamination; today, it provides an ultra-clean, uniform, and precisely controlled high-temperature environment.

The Original Problem: Contamination by Combustion

In early high-temperature applications, heat was generated by burning fuel like coal or gas. This created a significant challenge for processes that required purity.

The Need for a Barrier

Direct exposure to open flame and combustion gases would introduce unwanted contaminants to the material being heated. Byproducts like soot, ash, and volatile fumes could ruin sensitive processes like metal tempering or ceramic glazing.

How the "Muffle" Provided a Solution

The solution was to build a furnace with a dedicated inner chamber, known as the muffle. This chamber, typically made of refractory ceramic or brick, acted as a physical barrier.

The fuel was burned outside this chamber, and the heat transferred through the chamber walls to the sample inside. This indirect heating method ensured the material was never in direct contact with the fuel or its exhaust, protecting its integrity.

The Modern Evolution: The Shift to Electric Heat

The most significant evolution in muffle furnace design was the move away from combustion and toward clean, efficient electric heating.

The Rise of Electric Coils

Modern muffle furnaces almost exclusively use high-temperature electric heating coils. These elements are typically embedded within the insulating walls of the furnace chamber.

This change immediately eliminated the original source of contamination. There is no fuel, no flame, and no exhaust, making the heating process inherently clean.

The Muffle's Enduring Role

Even without the threat of fuel contamination, the isolated chamber design remains essential. The term "muffle furnace" persists because this principle is still central to its function.

Today, the muffle chamber guarantees a highly uniform and stable thermal environment. Heat radiates evenly from all surrounding walls, preventing hot spots and ensuring the entire sample experiences the same temperature, which is critical for processes like ashing, sintering, and advanced materials research.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with specific characteristics that make it suitable for some applications but not others.

Indirect vs. Direct Heating

The indirect nature of the heating is slower than a furnace where a flame directly heats the sample. However, the trade-off is superior temperature uniformity and sample purity.

High-Temperature Specialization

Muffle furnaces are built with heavy insulation and robust heating elements designed to reach and hold very high temperatures (often >1000°C). They are inefficient and ill-suited for low-temperature applications.

Thermal Inertia

The thick, insulating firebrick walls that contain the heat so effectively also store it. This means muffle furnaces take longer to heat up and cool down compared to less insulated ovens, a factor known as high thermal inertia. This can be an advantage for maintaining stability but a disadvantage for processes requiring rapid temperature changes.

Making the Right Choice for Your Goal

Understanding the furnace's core design principle helps clarify its ideal use case.

- If your primary focus is historical context: The muffle was a physical shield designed to protect a sample from the dirty byproducts of burning fuel.

- If your primary focus is modern applications: The muffle design ensures a highly controlled, uniform, and contamination-free environment using clean electric heat for precise thermal processing.

- If your primary focus is selecting equipment: Choose a muffle furnace when sample purity and temperature uniformity are more critical than the absolute speed of heating.

Ultimately, the muffle furnace evolved from a clever solution for "dirty" heat into a modern standard for precision high-temperature work.

Summary Table:

| Aspect | Initial Purpose | Modern Evolution |

|---|---|---|

| Heating Method | Indirect heating via combustion outside muffle | Electric heating elements embedded in walls |

| Key Benefit | Isolation from fuel contaminants (e.g., ash, soot) | Ultra-clean, uniform, and precise temperature control |

| Primary Use | Protecting materials in processes like metal tempering | High-temperature applications like ashing and sintering |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Ensure precise, contamination-free thermal processing—contact us today to discuss how our furnaces can enhance your research and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination