In laboratory research, a box type electric furnace serves as a fundamental tool for the controlled thermal processing of materials. They are used for a wide range of applications, including the synthesis of new materials like ceramics and nanomaterials, quality testing, annealing metals to improve their properties, and conducting heat treatment experiments across the fields of metallurgy, chemistry, and materials science.

The core value of a box furnace in a research setting is not just its ability to get hot, but its capacity to provide a precisely controlled and repeatable thermal environment. This control is the key that unlocks the ability to create, test, and modify materials at a fundamental level.

The Core Function: Precision Thermal Processing

A laboratory furnace is essentially a highly controllable oven designed for scientific purposes. Its primary job is to apply a specific, uniform temperature profile to a material sample over a set period of time. This enables three critical research activities.

Material Synthesis and Creation

Researchers use furnaces to create materials that don't exist in nature or to produce known materials with highly specific properties.

The high heat facilitates chemical reactions and physical phase changes needed for synthesis. This is common in the creation of advanced ceramics, specialized glass, and even cutting-edge materials like graphene and other nanomaterials.

Material Analysis and Testing

Furnaces are used to understand how materials behave under thermal stress. This is a critical part of quality control and fundamental research.

By heating a sample, researchers can perform element analysis, study phase transformation processes, or observe microstructural evolution. For instance, an organic sample might be carbonized to determine its composition.

Material Treatment and Modification

Often, the goal is to change the properties of an existing material. The furnace provides the energy needed to alter a material's internal structure.

Processes like annealing use heat to make metals less brittle and more ductile. Similarly, curing uses a furnace to solidify polymers, and sintering uses heat to fuse powdered materials into a solid mass without melting them.

Specialized Furnaces for Advanced Research

While the standard box furnace is a versatile workhorse, specialized research often requires more advanced capabilities, particularly control over the sample's atmosphere.

The Standard Box Furnace

This is the most common type, operating in ambient air. It is ideal for general-purpose applications like firing ceramics, basic heat treatments, and quality testing where the material's interaction with oxygen is not a concern.

The Vacuum Furnace

For many advanced materials, reacting with oxygen at high temperatures is detrimental. A vacuum furnace removes the air, creating a clean environment.

This is essential for synthesizing sensitive materials like quantum materials, preventing oxidation during the heat treatment of reactive metals, and simulating the extreme conditions of outer space for material testing.

The Tube Furnace

A tube furnace uses a long, narrow ceramic or quartz tube as its heating chamber. This design is perfect for processing small samples or when a specific gas (like nitrogen or argon) needs to be flowed over the material.

This makes it highly effective for experiments in chemistry and physics requiring precise environmental control, such as chemical vapor deposition (CVD) or specific types of element analysis.

Understanding the Key Trade-offs

Choosing the right furnace involves balancing capability, complexity, and cost. Misunderstanding these trade-offs can compromise experimental results.

Temperature vs. Cost

Higher maximum temperatures and better temperature uniformity come at a significantly higher cost. A furnace for sintering basic ceramics at 1200°C is far less complex than one needed for melting specialty alloys at 1700°C.

Atmosphere Control vs. Simplicity

A standard air furnace is simple to operate and maintain. A vacuum furnace, while providing critical protection from oxidation, adds complexity with its vacuum pumps, seals, and pressure monitoring systems.

Chamber Size vs. Efficiency

A larger chamber offers more versatility for bigger samples but requires more power to heat and takes longer to reach the target temperature and cool down. For small, rapid experiments, a smaller furnace is far more efficient.

Making the Right Choice for Your Goal

Your specific research objective is the most important factor in selecting a furnace.

- If your primary focus is general materials processing: A standard box furnace with an appropriate temperature range for firing ceramics, annealing common metals, or basic heat treatments is the most practical choice.

- If your primary focus is developing sensitive new materials: A vacuum furnace is non-negotiable to prevent oxidation and ensure the purity of materials like advanced alloys, nanomaterials, or quantum materials.

- If your primary focus is precise chemical synthesis or analysis: A tube furnace offers the best control for flowing specific gases over a sample, which is critical for many chemical reactions and analytical techniques.

Ultimately, the laboratory furnace is a foundational tool that transforms theoretical material concepts into tangible, testable reality.

Summary Table:

| Application Area | Key Uses | Ideal Furnace Type |

|---|---|---|

| Material Synthesis | Creating ceramics, nanomaterials, graphene | Standard Box or Tube Furnace |

| Material Analysis | Element analysis, phase transformation studies | Standard Box or Tube Furnace |

| Material Treatment | Annealing, curing, sintering metals and polymers | Standard Box Furnace |

| Advanced Research | Preventing oxidation, sensitive material synthesis | Vacuum or Tube Furnace |

Ready to elevate your laboratory's capabilities with precision high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, whether for material synthesis, analysis, or treatment. Contact us today to discuss how our solutions can enhance your research efficiency and outcomes!

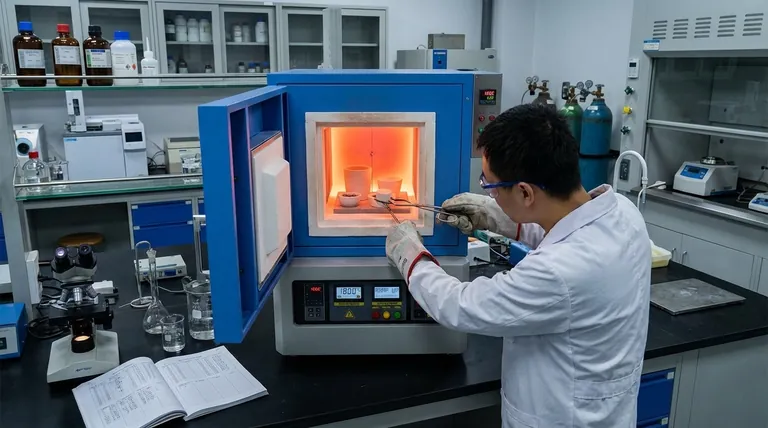

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development