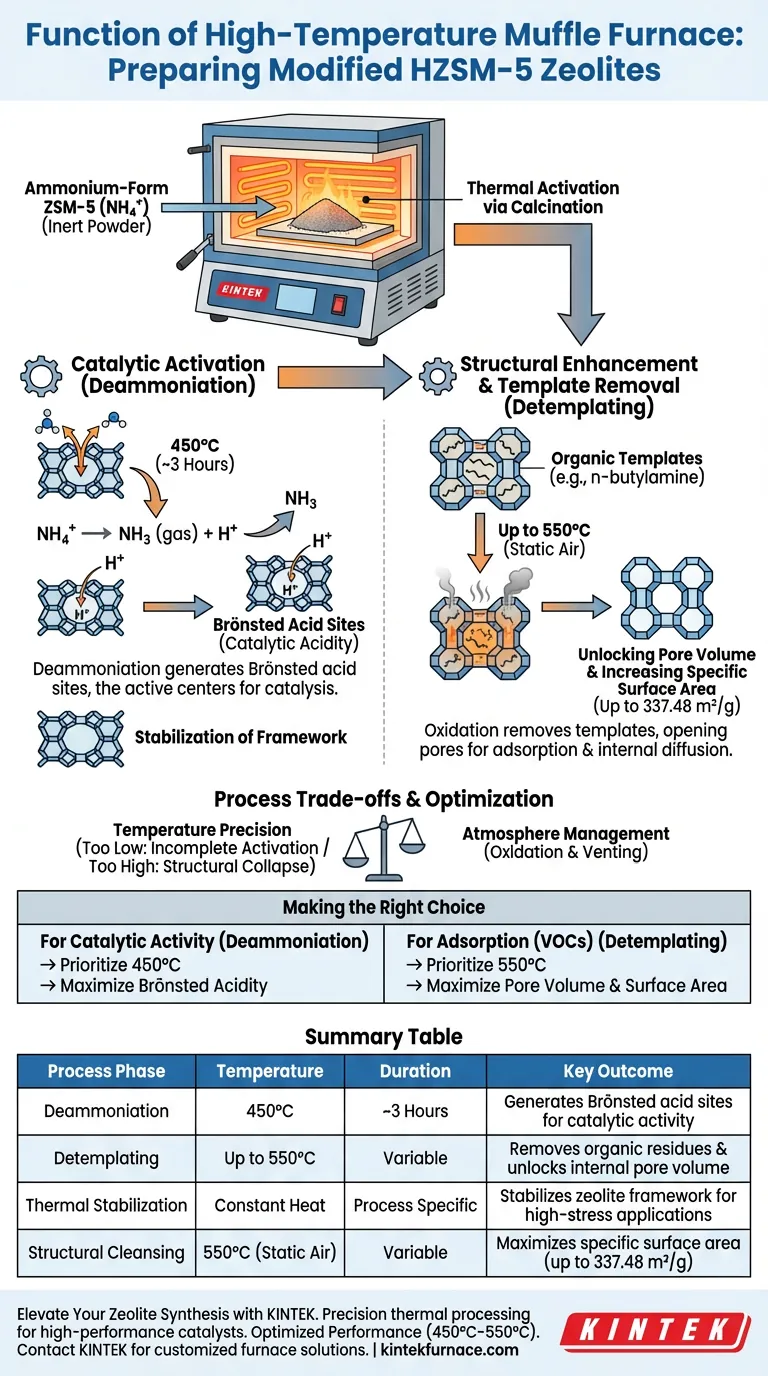

The primary function of a high-temperature muffle furnace in this context is the thermal activation of the zeolite through calcination. specifically, it is used to convert ammonium-form ZSM-5 into its protonated form (HZSM-5) by maintaining a constant temperature, typically around 450°C. This thermal treatment drives the decomposition of ammonium ions ($NH_4^+$) into ammonia gas ($NH_3$) and protons ($H^+$), which is the critical step for generating the material's catalytic acidity.

Core Takeaway The muffle furnace acts as a reactor for deammoniation, a process that chemically transforms the inert ammonium-form zeolite into the catalytically active HZSM-5. By precisely controlling heat, it removes volatile components to create essential Brönsted acid sites while simultaneously oxidizing organic templates to unlock the zeolite's pore structure.

The Mechanism of Catalytic Activation

To understand the furnace's role, you must look beyond simple heating. It is driving a specific chemical phase change required to make the material useful.

Generating Brönsted Acid Sites

The most critical output of the muffle furnace is the creation of acidity. The primary reference indicates that by holding the material at 450°C for approximately 3 hours, the furnace facilitates the release of ammonia gas. When the ammonia leaves, protons ($H^+$) remain attached to the zeolite framework. These protons form the Brönsted acid sites, which are the active centers responsible for the zeolite's catalytic performance in chemical reactions.

Stabilization of the Framework

Beyond generating acidity, this thermal treatment stabilizes the physical structure of the zeolite. The conversion from the ammonium form to the proton form (HZSM-5) ensures the material is thermally stable and chemically prepared for harsh operating environments, such as gas oil catalytic cracking.

Structural Enhancement and Template Removal

While the primary goal is acidification, the high-temperature environment serves a secondary, equally vital purpose regarding the material's physical architecture.

Removing Organic Templates (Detemplating)

During synthesis, organic agents like n-butylamine are often used to guide the zeolite's growth. These agents become trapped inside the crystal lattice. The muffle furnace, operating at temperatures up to 550°C in static air, oxidizes and thermally decomposes these organic residues.

Unlocking Pore Volume

Removing these templates is essential to "open" the zeolite. This process clears the ten-membered ring intersecting channels, significantly increasing the specific surface area (up to 337.48 m²/g). Without this step, the pores would remain blocked, rendering the material useless for adsorption or catalysis requiring internal diffusion.

Understanding Process Trade-offs

Precise control over the furnace parameters is necessary to balance chemical activation with structural integrity.

Temperature Precision vs. Structural Damage

You must maintain a specific thermal window. If the temperature is too low (insufficient thermal energy), the decomposition of ammonium ions or organic templates will be incomplete, resulting in low acidity and blocked pores. Conversely, excessive heat can lead to the collapse of the zeolite framework or the loss of active sites, degrading the material's performance.

Atmosphere Management

The furnace typically operates under static air conditions to facilitate oxidation. This is critical for removing organic templates (combustion). However, the release of ammonia gas during deammoniation requires that the furnace environment allows for the effective venting of off-gases to prevent equilibrium shifts that could inhibit the reaction.

Making the Right Choice for Your Goal

The specific settings you use for the muffle furnace should be dictated by the final application of your HZSM-5 zeolite.

- If your primary focus is Catalytic Activity: Prioritize the deammoniation profile (450°C) to maximize the generation of Brönsted acid sites without subjecting the active sites to excessive thermal stress.

- If your primary focus is Adsorption (VOCs): Prioritize a higher temperature calcination (550°C) to ensure the complete removal of organic templates and the maximization of pore volume and surface area.

Ultimately, the high-temperature muffle furnace is the tool that transforms ZSM-5 from a raw synthesis powder into a functional, high-performance catalyst.

Summary Table:

| Process Phase | Temperature | Duration | Key Outcome |

|---|---|---|---|

| Deammoniation | 450°C | ~3 Hours | Generates Brönsted acid sites for catalytic activity |

| Detemplating | Up to 550°C | Variable | Removes organic residues & unlocks internal pore volume |

| Thermal Stabilization | Constant Heat | Process Specific | Stabilizes zeolite framework for high-stress applications |

| Structural Cleansing | 550°C (Static Air) | Variable | Maximizes specific surface area (up to 337.48 m²/g) |

Elevate Your Zeolite Synthesis with KINTEK

Precision thermal processing is the difference between an inert powder and a high-performance catalyst. KINTEK provides the advanced heating technology required to unlock the full potential of your HZSM-5 materials.

Why Choose KINTEK?

- Expert R&D & Manufacturing: Our systems are designed for high-accuracy thermal activation and deammoniation.

- Customizable Solutions: From Muffle and Tube furnaces to Vacuum and CVD systems, we tailor equipment to your specific lab requirements.

- Optimized Performance: Achieve the precise temperature windows (450°C–550°C) necessary to maximize Brönsted acidity without structural collapse.

Ready to enhance your lab’s efficiency and material quality? Contact KINTEK today to discuss your customized furnace solution!

Visual Guide

References

- Mirna Oliveira Sant’Ana, M. Souza. Study of the Conversion of Postconsumer Polystyrene on CeO<sub>2</sub>/HZSM-5 Type Materials. DOI: 10.4236/msce.2024.124003

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the function of a muffle furnace in Ba1-xCaxTiO3 calcination? Ensure Purity & Precision in Ceramic Synthesis

- What critical support does an industrial muffle furnace provide in mineral dielectric evolution? Real-Time Insights

- How does a high-temperature muffle furnace control the silver ion release rate? Master Precision Geopolymer Sintering

- What role does a Muffle furnace play in chemical reactions? Achieve Precise, Contamination-Free Thermal Processing

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in nitrogen-doped carbon precursor synthesis? Key Roles in Thermal Condensation

- How are muffle furnaces used in high-temperature sintering within the pharmaceutical industry? Ensure Precision and Purity in Drug Development

- How do muffle furnaces maintain temperature control and prevent contamination? Achieve Clean, Uniform Heating for Your Lab