In pharmaceutical manufacturing, muffle furnaces are used for high-temperature sintering by providing an exceptionally uniform and controlled heating environment. This allows powdered materials to be fused into a solid, porous mass without melting, a critical process for creating advanced drug delivery systems and biocompatible implants where consistency and purity are paramount.

The core value of a muffle furnace in pharmaceuticals extends far beyond a single process. Its design provides a high-purity, contaminant-free heating chamber, making it an indispensable tool for quality control, analytical testing, and materials research where product integrity cannot be compromised.

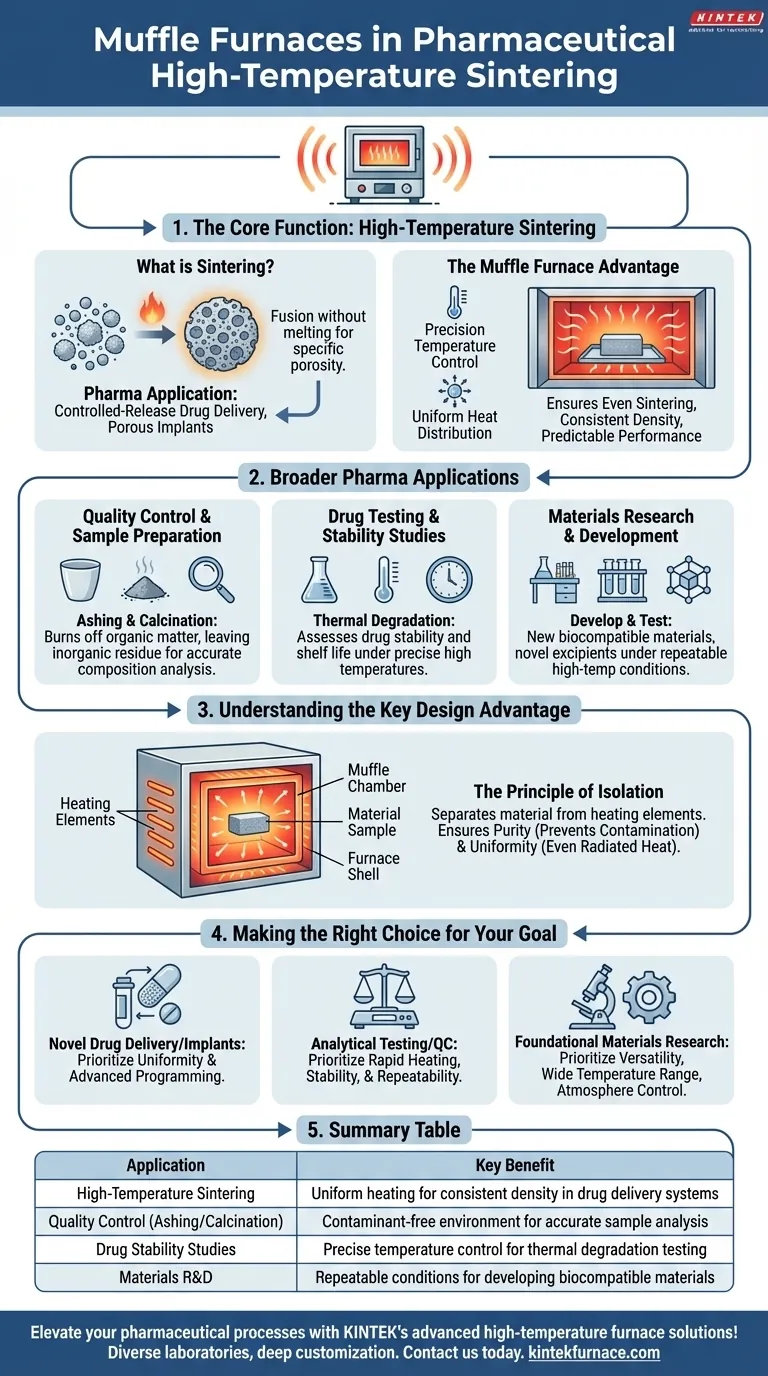

The Core Function: High-Temperature Sintering

What is Sintering?

Sintering is a thermal treatment process for compacting and forming a solid mass of material from a powder. It is heated to a high temperature, but below its melting point, causing the individual particles to bond and fuse.

This process is fundamental for creating materials with specific porosity and density, which is highly valuable in advanced manufacturing.

Why Sintering Matters in Pharma

In the pharmaceutical industry, sintering is used to fabricate components like controlled-release drug delivery systems or porous ceramic implants.

The final structure's porosity directly influences its function, such as the rate at which a drug is released. Therefore, the sintering process must be perfectly controlled.

The Muffle Furnace Advantage

The primary advantage of a muffle furnace for sintering is its precision temperature control and uniform heat distribution.

This uniformity ensures that the entire powdered mass sinters evenly, resulting in a final product with consistent density and predictable performance, which is a non-negotiable requirement for medical devices and drug carriers.

Broader Applications in Pharmaceutical Processes

While sintering is a key application, the muffle furnace's capabilities are utilized across the pharmaceutical lifecycle.

Quality Control and Sample Preparation

Muffle furnaces are essential for ashing and calcination. These processes use high heat to burn off all organic matter from a sample, leaving only inorganic residue.

This is a critical step in quality control and analytical testing to determine the composition of pharmaceutical compounds or raw materials accurately.

Drug Testing and Stability Studies

The furnace's controlled environment is ideal for conducting thermal degradation studies. By subjecting a drug substance to precise high temperatures, researchers can assess its stability and shelf life.

This data is crucial for regulatory submissions and ensuring the safety and efficacy of a drug over time.

Materials Research and Development

Muffle furnaces are workhorses in pharmaceutical research and development (R&D). They are used to develop and test new biocompatible materials for implants or novel excipients for drug formulations.

Their ability to create precise, repeatable high-temperature conditions makes them indispensable for innovation and material science exploration.

Understanding the Key Design Advantage

The defining feature of a muffle furnace is not just its heat, but its architecture.

The Principle of Isolation

A muffle furnace contains an inner chamber, or "muffle," that separates the material being heated from the heating elements and any potential contaminants.

In older or fuel-fired designs, this prevented impurities from the combustion process from reaching the sample. In modern electric furnaces, it still serves to protect the sample from direct contact with the heating elements.

Ensuring Purity and Uniformity

This isolation is the furnace's most critical feature for pharmaceutical use. It prevents contamination, ensuring the absolute purity of the drug substance or material being processed.

Furthermore, the muffle heats up and radiates that heat evenly onto the sample from all sides, which is the mechanism that guarantees a uniform temperature environment.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your specific objective.

- If your primary focus is creating novel drug delivery systems or implants: You need a furnace with exceptional temperature uniformity and advanced programming to control the sintering profile precisely.

- If your primary focus is analytical testing and quality control: Prioritize a furnace that offers rapid heating, documented temperature stability, and high repeatability for processes like ashing.

- If your primary focus is foundational materials research: A versatile furnace with a wide temperature range and options for atmosphere control will provide the flexibility needed for exploration.

Ultimately, the muffle furnace is a tool for achieving certainty, ensuring every high-temperature process yields a pure, consistent, and reliable result.

Summary Table:

| Application | Key Benefit |

|---|---|

| High-Temperature Sintering | Uniform heating for consistent density in drug delivery systems |

| Quality Control (Ashing/Calcination) | Contaminant-free environment for accurate sample analysis |

| Drug Stability Studies | Precise temperature control for thermal degradation testing |

| Materials R&D | Repeatable conditions for developing biocompatible materials |

Elevate your pharmaceutical processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for sintering, quality control, and materials research. Contact us today to discuss how our furnaces can enhance purity, consistency, and innovation in your work!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing