In chemical reactions, a muffle furnace serves as a high-precision, isolated environment for thermal processing. Its primary role is to provide extremely stable and uniform high temperatures while its internal chamber, the "muffle," isolates the chemical sample from the heating elements and any external contaminants. This dual function of precise temperature control and environmental isolation is critical for regulating reaction rates, improving product yield, and ensuring purity.

The core value of a muffle furnace is not simply the high heat it generates, but the separation it provides. By creating a chemically inert and thermally uniform chamber isolated from the heating source, it ensures a reaction proceeds under predictable and pure conditions that are impossible to achieve with direct heating methods.

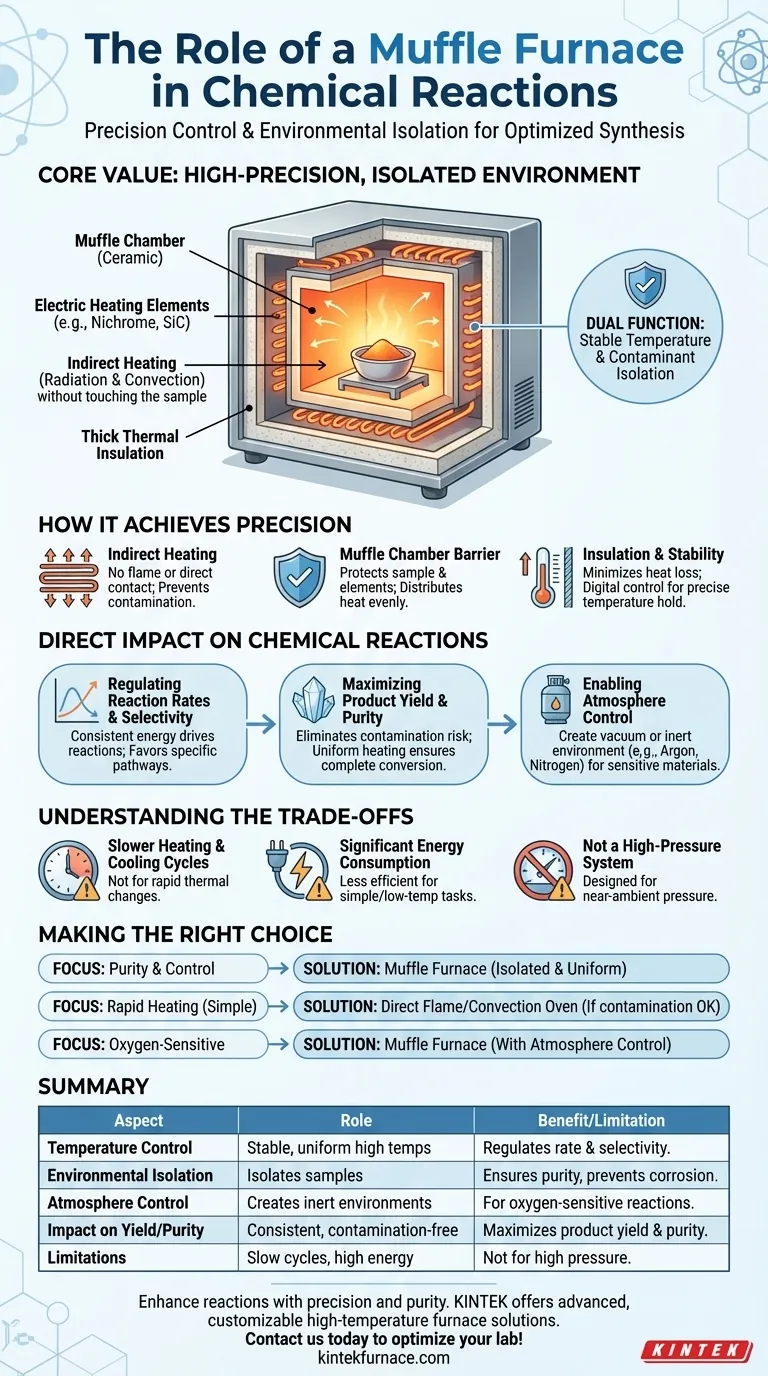

How a Muffle Furnace Achieves Precision Control

The design of a muffle furnace is deliberately engineered to eliminate variables that can compromise a chemical reaction. Its operation is based on providing heat that is both stable and clean.

The Principle of Indirect Heating

A muffle furnace does not expose the sample to a flame or direct contact with heating elements. Instead, electric heating elements, often made of nichrome or silicon carbide, line the walls of the furnace.

When current passes through these elements, they heat up and transfer energy into the chamber through thermal radiation and convection. This indirect approach is the key to preventing contamination.

The Role of the Muffle Chamber

The "muffle" is the inner chamber that holds the sample. It is typically made of a high-temperature, chemically resistant ceramic like alumina.

This chamber acts as a crucial barrier. It protects the sample from any particles shed by the heating elements and protects the heating elements from potentially corrosive fumes produced by the reaction. Its material and shape also help distribute heat evenly.

Insulation and Temperature Stability

The entire chamber is wrapped in thick layers of thermal insulation. This minimizes heat loss, allowing the furnace to efficiently reach and maintain very high temperatures (often over 1000°C) with exceptional stability. A digital controller monitors the internal temperature and adjusts power to the heating elements, ensuring the target temperature is held precisely.

The Direct Impact on Chemical Reactions

The controlled environment provided by a muffle furnace directly influences the outcome of chemical synthesis and analysis.

Regulating Reaction Rates and Selectivity

Many chemical reactions have a high activation energy and only proceed at a significant rate at elevated temperatures. The furnace's stable heat provides the consistent energy needed to drive these reactions forward predictably.

Furthermore, by precisely controlling the temperature, a chemist can favor a specific reaction pathway over others, a concept known as selectivity.

Maximizing Product Yield and Purity

Because the reaction is isolated from the heating elements and outside atmosphere, the risk of contamination is virtually eliminated. This results in a much purer final product.

The uniform heat distribution also ensures that the entire batch of reactants is processed under the same conditions, leading to a more complete conversion and therefore a higher product yield.

Enabling Atmosphere Control

The sealed nature of the muffle chamber allows for modifying the internal environment. Air can be evacuated to create a vacuum, or the chamber can be purged and filled with an inert gas like argon or nitrogen. This is essential for reactions involving materials that are sensitive to oxygen or moisture.

Understanding the Trade-offs

While powerful, a muffle furnace is not the universal solution for all heating needs. Understanding its limitations is key to using it effectively.

Slower Heating and Cooling Cycles

The heavy insulation and indirect heating method that create temperature stability also mean the furnace heats up and cools down slowly. It is not suited for applications requiring rapid thermal changes.

Significant Energy Consumption

Maintaining extremely high temperatures requires a continuous and substantial input of electrical energy. For simple drying or low-temperature processes, it can be less energy-efficient than a conventional lab oven.

Not a High-Pressure System

While the high temperatures in a muffle furnace can sometimes reduce the need for high pressure to drive a reaction, the furnace itself is not a pressure vessel. It is designed to operate at or near ambient pressure.

Making the Right Choice for Your Goal

Select your heating method based on the specific requirements of your chemical process.

- If your primary focus is purity and control: A muffle furnace is the ideal choice due to its isolated and uniform heating environment.

- If your primary focus is rapid heating for simple processes: A direct flame or a standard convection oven may be more efficient if contamination is not a concern.

- If your reaction is highly sensitive to oxygen: A muffle furnace with atmosphere control capabilities is essential for creating the required inert environment.

Ultimately, a muffle furnace empowers scientists and engineers to move beyond simple heating and achieve precise, repeatable control over the chemical transformation itself.

Summary Table:

| Aspect | Role in Chemical Reactions |

|---|---|

| Temperature Control | Provides stable, uniform high temperatures to regulate reaction rates and selectivity. |

| Environmental Isolation | Uses a muffle chamber to isolate samples from contaminants, ensuring purity and preventing corrosion. |

| Atmosphere Control | Allows creation of inert environments (e.g., with argon or nitrogen) for oxygen-sensitive reactions. |

| Impact on Yield and Purity | Maximizes product yield and purity through consistent, contamination-free heating. |

| Limitations | Slower heating/cooling, high energy use, and not suitable for high-pressure applications. |

Ready to enhance your chemical reactions with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need reliable temperature control, environmental isolation, or atmosphere management, we have the expertise to support your goals. Contact us today to discuss how our furnaces can optimize your lab's efficiency and results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO