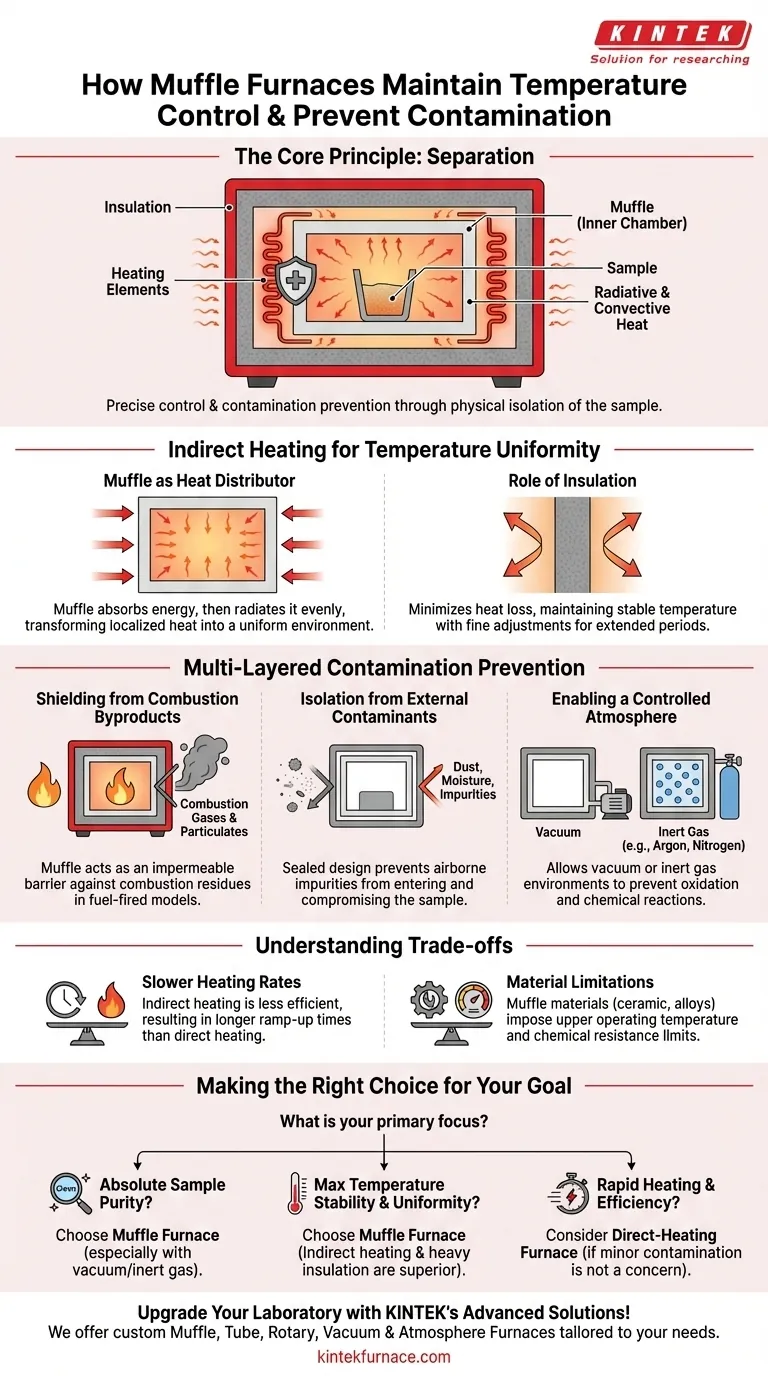

At its core, a muffle furnace achieves precise temperature control and prevents contamination by using a design principle of separation. It places the material to be heated inside an inner chamber, or "muffle," which is physically isolated from the heating elements and the external environment, ensuring heat is transferred indirectly and cleanly.

The defining feature of a muffle furnace is not the heat source itself, but the use of this isolated inner chamber. This physical barrier is the key to delivering uniform, non-contaminating heat to a sample.

How Indirect Heating Achieves Temperature Uniformity

A muffle furnace does not expose the sample directly to the heat source. Instead, it heats the muffle, which in turn heats the sample. This indirect method is fundamental to its precise performance.

The Muffle as a Heat Distributor

The heating elements (or gas flame in some models) heat the outside of the muffle. The muffle, typically made of a high-thermal-conductivity ceramic, absorbs this energy and then radiates it evenly throughout the inner chamber.

This process transforms the intense, localized energy of the heating elements into a gentle, uniform thermal environment. It relies on both radiative and convective heat transfer to ensure the entire sample reaches the target temperature consistently.

The Role of Insulation

The entire assembly is housed within a heavily insulated outer casing. This insulation minimizes heat loss to the outside, which is critical for maintaining a stable internal temperature without constant, drastic energy fluctuations.

This stability allows the furnace's control system to make fine adjustments, holding the temperature at a precise setpoint for extended periods.

A Multi-Layered Approach to Preventing Contamination

The same design principle that ensures temperature uniformity also provides a robust barrier against contamination. The isolation of the sample is the primary defense.

Shielding from Combustion Byproducts

In fuel-fired furnaces, the combustion process creates gases and particulates that could react with and contaminate the sample. The muffle acts as an impermeable barrier, keeping these combustion byproducts completely separate from the heating chamber.

Isolation from External Contaminants

The sealed, enclosed design of the furnace prevents airborne dust, moisture, and other impurities from the surrounding atmosphere from entering the chamber and compromising the sample's integrity.

This makes the muffle furnace ideal for high-purity applications like ashing, materials analysis, and creating advanced ceramics, where even trace contaminants can alter the results.

Enabling a Controlled Atmosphere

Because the chamber is isolated, the atmosphere inside it can be controlled. Air can be removed to create a vacuum, which prevents oxidation and other chemical reactions for highly sensitive materials.

Alternatively, the chamber can be purged and filled with an inert gas (like argon or nitrogen) to create a non-reactive environment, further protecting the sample from unwanted changes like carbonization.

Understanding the Trade-offs

While highly effective, the muffle furnace design comes with inherent trade-offs that are important to understand for any application.

Slower Heating Rates

Indirect heating is inherently less efficient than direct heating. Because the energy must first heat the muffle before it can heat the sample, ramp-up times are generally longer compared to a direct-heating furnace.

Material Limitations

The muffle itself is a consumable component, though a long-lasting one. It must be made from materials, like ceramic or high-temperature alloys, that can withstand extreme thermal stress.

These materials can also impose an upper limit on the furnace's operating temperature and may not be suitable for use with certain highly aggressive gases or vapors that could degrade them over time.

Making the Right Choice for Your Goal

Selecting the correct heating approach depends entirely on the priorities of your process.

- If your primary focus is absolute sample purity: A muffle furnace is the standard, especially one capable of maintaining a vacuum or inert gas atmosphere.

- If your primary focus is maximum temperature stability and uniformity: The indirect heating and heavy insulation of a well-designed muffle furnace are superior to direct-heating methods.

- If your primary focus is rapid heating and efficiency: For applications where minor atmospheric contamination is not a concern, a direct-heating furnace may be a more practical choice.

By understanding that the furnace's power lies in its separation principle, you can confidently leverage it to achieve clean and precise thermal processing.

Summary Table:

| Feature | How It Works | Benefit |

|---|---|---|

| Indirect Heating | Heating elements warm the muffle, which radiates heat evenly to the sample | Ensures uniform temperature distribution and precise control |

| Insulated Design | Outer casing minimizes heat loss | Maintains stable temperatures with fine adjustments |

| Contamination Prevention | Muffle barrier isolates sample from combustion byproducts and external impurities | Protects sample purity, ideal for ashing and materials analysis |

| Controlled Atmosphere | Allows vacuum or inert gas environments | Prevents oxidation and chemical reactions for sensitive materials |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure precise temperature control and contamination prevention for diverse applications. Contact us today to discuss how our furnaces can enhance your experimental efficiency and reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing