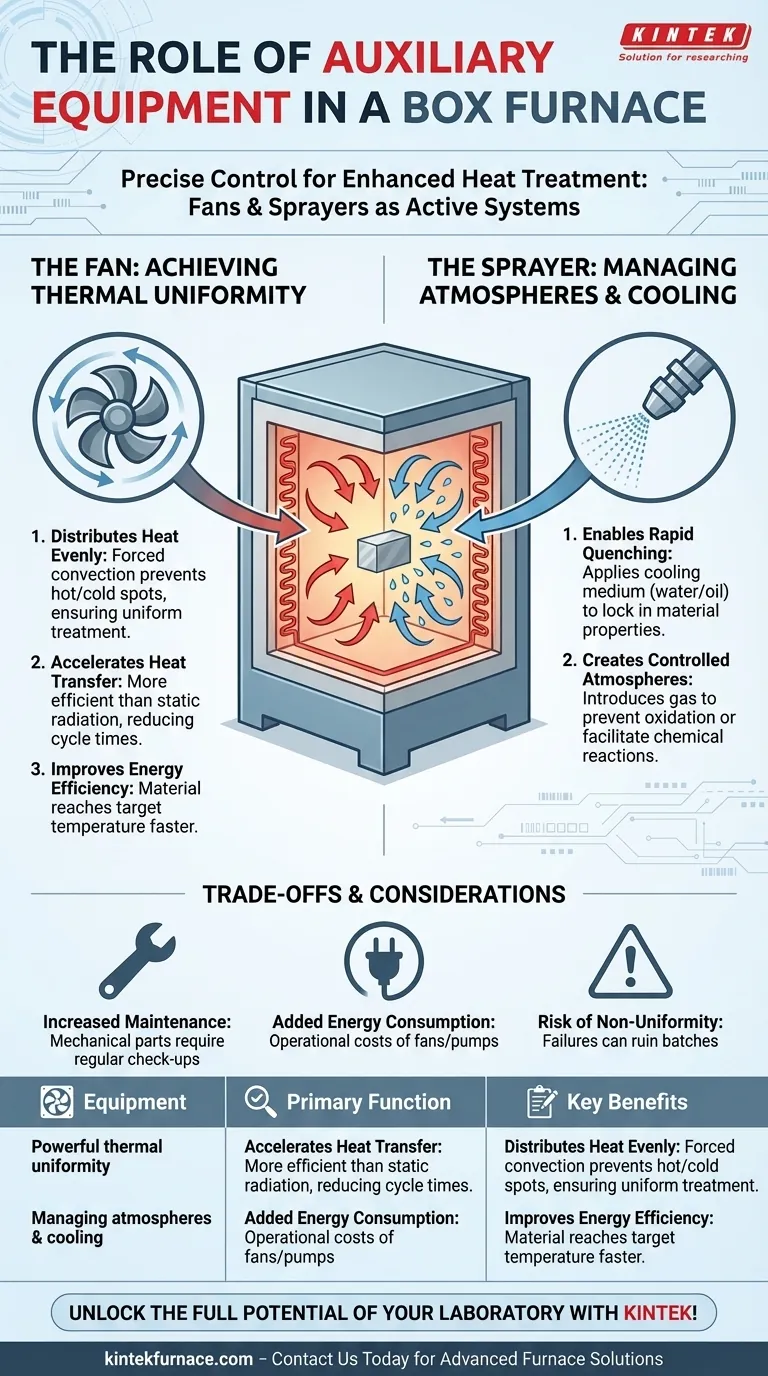

In a box furnace, auxiliary equipment like fans and sprayers serve one primary purpose: to precisely control the internal environment. They are not merely accessories but active systems used to manipulate heat transfer and atmospheric conditions, directly improving the quality and consistency of the final product.

The core function of fans and sprayers is to transform a static heating chamber into a dynamic, controlled processing environment. Fans ensure uniform temperature through convection, while sprayers enable rapid cooling or introduce specific atmospheres required for advanced material treatments.

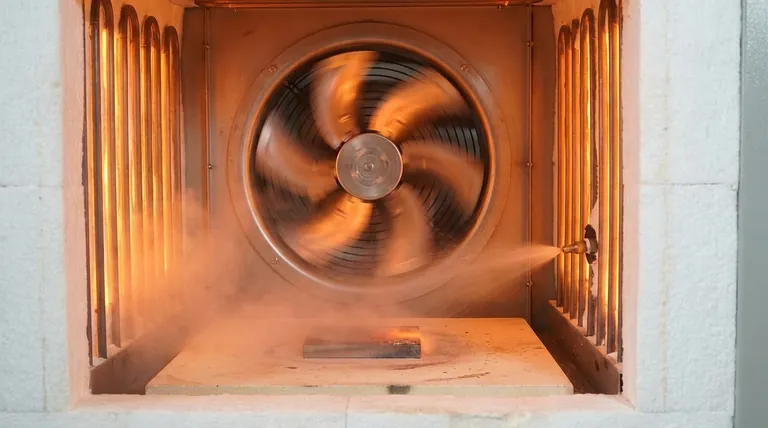

The Fan's Role: Achieving Thermal Uniformity

A box furnace, by its nature, can develop hot and cold spots. A circulation fan is the primary tool used to combat this thermal inconsistency.

Distributing Heat Evenly

The fan forces the movement of air or a specific process gas throughout the furnace chamber. This constant circulation prevents stratification and ensures the workpiece is heated uniformly from all sides.

Without a fan, heat transfer relies mainly on radiation, which can lead to uneven treatment. Parts of the material closer to the heating elements get hotter faster, causing internal stresses or inconsistent material properties.

Accelerating Heat Transfer

Forced convection, created by the fan, is a much more efficient method of heat transfer than static radiation or conduction alone.

This accelerated heating can significantly reduce cycle times, improving throughput and energy efficiency. The material reaches its target temperature faster and more uniformly.

The Sprayer's Role: Managing Atmospheres and Cooling

Sprayers introduce a liquid or gas into the furnace, typically for quenching or creating a specific atmosphere. They are essential for processes that require rapid changes in temperature or a controlled chemical environment.

Enabling Rapid Quenching

For many metallurgical processes, such as the hardening of steel, the rate of cooling is just as critical as the heating temperature.

Sprayers are used to rapidly and evenly apply a quenching medium, like water or oil, to the workpiece. This locks in the desired crystalline structure and material properties.

Creating Controlled Atmospheres

In some applications, sprayers can be used to introduce substances that create a protective or reactive atmosphere.

This can prevent oxidation on the material's surface or facilitate specific chemical reactions needed for processes like carburizing.

Understanding the Trade-offs and Considerations

While essential for many processes, the inclusion of fans and sprayers introduces complexity and potential failure points that must be managed.

Increased Maintenance Requirements

Fans and sprayers are mechanical systems with moving parts, motors, and nozzles. They require regular inspection and maintenance to prevent failures that could ruin a batch or damage the furnace.

Added Energy Consumption

These systems consume additional electrical power. The operational cost of running fans and pumps must be factored into the overall cost of the heat treatment process.

The Risk of Non-Uniformity

A poorly designed or failing system can create more problems than it solves. A clogged spray nozzle or a malfunctioning fan can lead to extreme non-uniformity in cooling or heating, resulting in a scrapped part.

Applying This to Your Process

Choosing and utilizing this equipment depends entirely on the desired outcome for your material.

- If your primary focus is consistent heating for large or complex parts: A circulation fan is non-negotiable to ensure temperature uniformity and prevent defects.

- If your primary focus is achieving specific hardness or material properties: A sprayer system for quenching is a critical component for controlling the cooling rate.

- If your primary focus is process efficiency and speed: Both fans and sprayers can significantly reduce cycle times, but this benefit must be weighed against their maintenance and energy costs.

Ultimately, mastering the use of auxiliary equipment is key to unlocking the full potential of your box furnace for precise and repeatable results.

Summary Table:

| Equipment | Primary Function | Key Benefits |

|---|---|---|

| Fan | Ensures uniform temperature distribution | Prevents hot/cold spots, accelerates heat transfer, improves energy efficiency |

| Sprayer | Enables rapid quenching and atmosphere control | Facilitates precise material hardening, prevents oxidation, supports chemical reactions |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our deep customization capabilities ensure precise control for enhanced heat treatment processes. Contact us today to discuss how we can optimize your experiments and boost efficiency!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the function of a high-temperature Muffle Furnace in the two-step heat treatment of PTFE-coated Nickel Foam?

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution