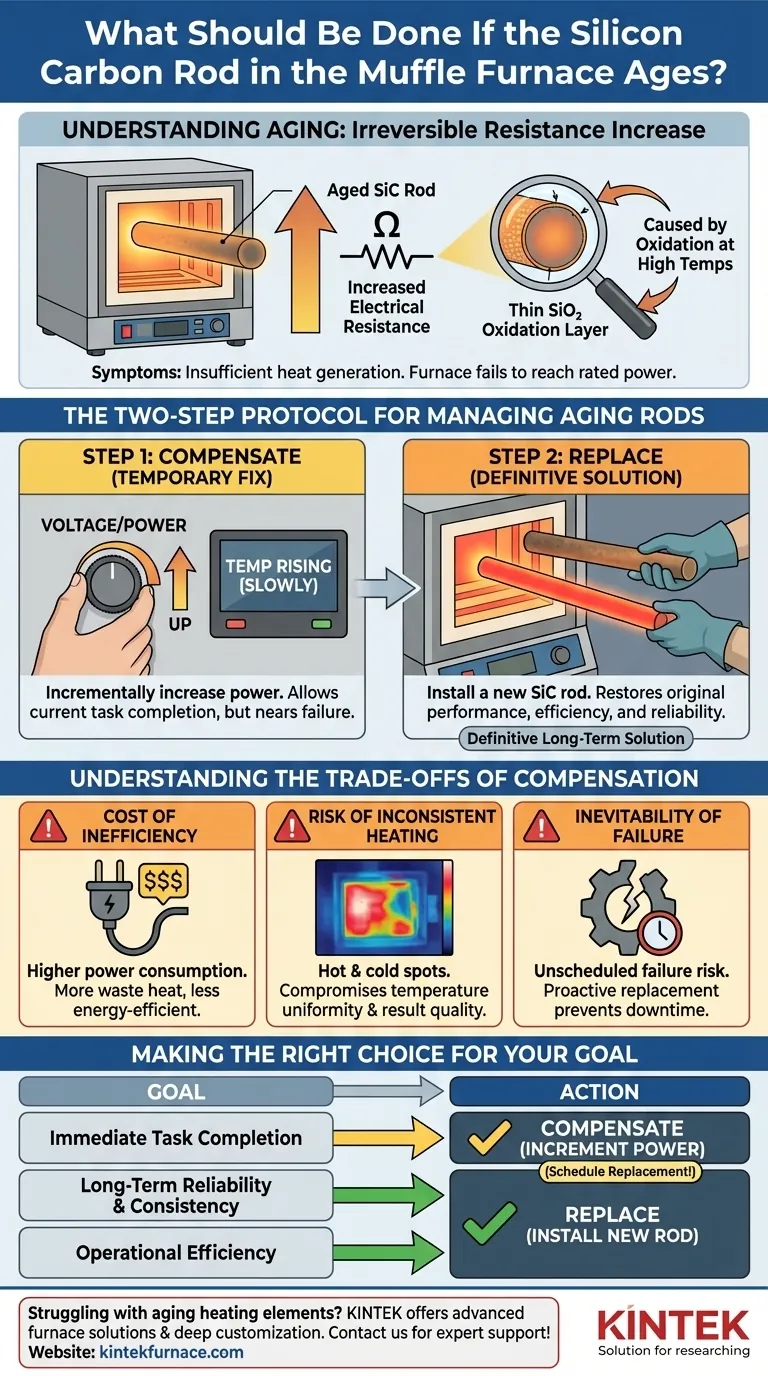

When your muffle furnace's silicon carbide rod ages, your immediate options are to first attempt compensation and then, if necessary, replace it. You can try to incrementally increase the power or voltage settings to regain the target temperature. If the furnace still fails to reach its rated power and produce sufficient heat, the rod has reached the end of its operational life and must be replaced with a new one.

Silicon carbide rod aging is an irreversible process caused by an increase in electrical resistance. While you can temporarily compensate by boosting power, replacement is the only definitive, long-term solution to restore the furnace's original performance and efficiency.

Understanding Silicon Carbide Rod Aging

To manage your equipment effectively, you must first understand the fundamental process of aging in these critical components. It is not simply a matter of time, but a specific physical change.

What "Aging" Actually Means

In the context of a silicon carbide (SiC) rod, "aging" refers to the gradual and permanent increase of its electrical resistance. As the rod is used at high temperatures, its internal structure changes, making it harder for electricity to pass through.

The direct symptom, as noted in operational manuals, is that heat generation becomes insufficient. The furnace controller may be demanding 100% power, but the aged rod can no longer draw enough current to reach the desired temperature.

The Cause: Oxidation and Resistance

The primary driver of aging is oxidation. Even in a normal air atmosphere, the silicon carbide material slowly reacts with oxygen at high operating temperatures.

This reaction forms a thin, insulating layer of silicon dioxide (SiO₂) on the rod. As this layer thickens over time and with continued use, the rod's overall electrical resistance rises.

The Vicious Cycle of Performance Loss

This increase in resistance creates a negative feedback loop. According to Ohm's law, power (heat) is a function of voltage and resistance (P = V²/R).

As resistance (R) increases, the power (P) generated at a given voltage (V) decreases. To get the same amount of heat, the furnace's control system must supply a higher voltage. This higher operational demand can, in turn, accelerate the oxidation process, leading to even faster aging.

A Two-Step Protocol for Managing an Aging Rod

When you notice a drop in your furnace's heating capability, follow this clear, two-step procedure.

Step 1: Compensate by Increasing Power

Your first course of action is to try and compensate for the increased resistance. Most modern furnace controllers do this automatically, but if you are managing it manually, you must incrementally increase the voltage or power setting.

This is a temporary measure. It allows you to complete an ongoing process or extend the rod's life for a short period, but it is a clear signal that the component is nearing failure.

Step 2: Replace the Rod

When compensation is no longer sufficient to reach the target temperature, or when the system has reached its maximum voltage output, replacement is the only remaining option.

Replacing a silicon carbide rod is a standard maintenance task, not a sign of a catastrophic problem. Treating it as a consumable part is key to predictable furnace operation.

Understanding the Trade-offs

Simply boosting the power to an aging rod is not a free solution. It comes with clear trade-offs that you must consider.

The Cost of Inefficiency

Running an aged rod at a higher voltage to achieve the same temperature is inherently less energy-efficient. You are consuming more electricity to overcome the rod's internal resistance, generating waste heat in the power supply system instead of the furnace chamber.

The Risk of Inconsistent Heating

An aging rod may not heat as uniformly as a new one. This can introduce hot and cold spots within the furnace chamber, compromising the temperature uniformity that is critical for many scientific and industrial processes. This can directly impact the quality and reproducibility of your results.

The Inevitability of Failure

Compensating for an aging rod is a stop-gap, not a solution. Pushing the component and the furnace's power supply to their limits increases the risk of an unscheduled failure during a critical experiment or production run. Proactive replacement is always preferable to reactive repair.

Making the Right Choice for Your Goal

Your strategy for dealing with an aging rod should align with your operational priorities.

- If your primary focus is immediate task completion: You can incrementally increase the power to finish a current experiment, but you should schedule maintenance and order a replacement rod immediately.

- If your primary focus is long-term reliability and consistency: Replace the aging silicon carbide rod as soon as you notice a consistent degradation in performance, rather than attempting to compensate.

- If your primary focus is operational efficiency: Replace the rod proactively, as running an aged rod at higher voltages wastes energy and increases operational costs for the same heat output.

Proactively managing the lifecycle of your heating elements is the foundation of a safe, efficient, and reliable furnace operation.

Summary Table:

| Action | Description | When to Use |

|---|---|---|

| Compensate | Incrementally increase power or voltage to regain target temperature. | Temporary measure when performance drops but furnace can still heat. |

| Replace | Install a new silicon carbide rod to restore original performance. | When compensation fails or for long-term reliability and efficiency. |

Struggling with aging heating elements in your lab furnace? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With exceptional R&D and in-house manufacturing, we offer deep customization to precisely meet your unique experimental needs—ensuring enhanced efficiency, consistent heating, and reliable performance. Don't let rod aging disrupt your processes—contact us today for expert support and tailored solutions!

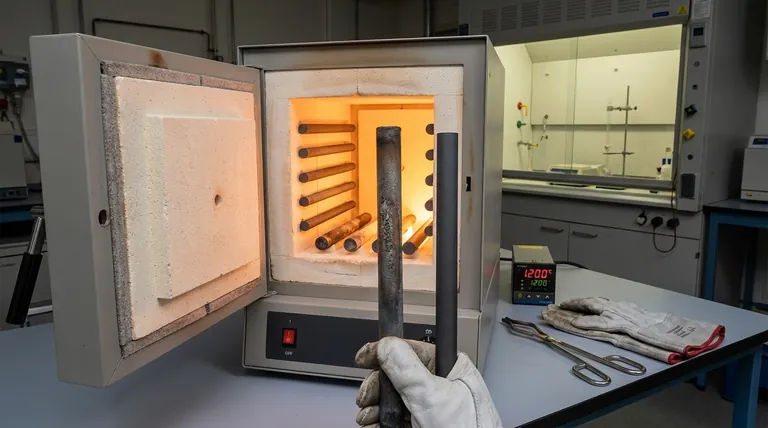

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- Why is silicon carbide resistant to chemical reactions in industrial furnaces? Unlock Durable High-Temp Solutions

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights

- Why are SIC heating elements resistant to chemical corrosion? Discover the Self-Protecting Mechanism