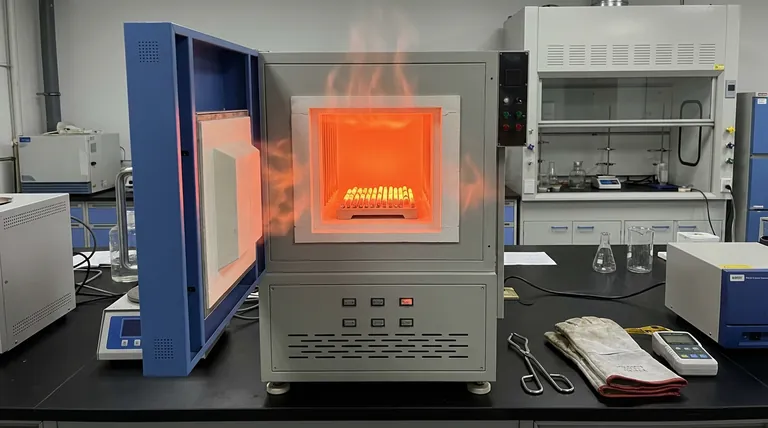

Annealing is the critical stabilization phase that transforms a raw chemical coating into a functional, reliable sensor component. Specifically, ceramic tubes coated with gas-sensing layers must be heated in a muffle furnace (typically at 400 °C) to mechanically fuse the sensing material to the substrate and electrodes while chemically purifying the layer.

The annealing process is not merely about drying; it is a structural integration step that ensures the sensor’s long-term reliability by eliminating volatile manufacturing byproducts and establishing a stable electrical interface.

Establishing Physical and Electrical Integrity

Securing Mechanical Adhesion

The primary purpose of annealing is to lock the sensing layer in place.

During the coating process, the gas-sensing material is deposited onto the ceramic tube. Without heat treatment, this layer is fragile and prone to peeling.

Annealing solidifies the interface between the sensing material and the ceramic substrate, preventing mechanical detachment during later handling or operation.

Creating Robust Electrical Contact

For a gas sensor to function, it must transmit changes in resistance to the readout electronics.

The sensing layer must form a reliable connection with the gold electrodes pre-printed on the ceramic tube.

Annealing strengthens this connection, often referred to as an ohmic contact, ensuring that electrical signals are transmitted efficiently without noise or resistance drift.

Stabilizing the Microstructure

Eliminating Residual Solvents

The coating process typically involves organic solvents or binders to make the sensing material spreadable.

If these organic components remain in the final sensor, they will interfere with gas interaction and cause unpredictable baseline shifts.

The high temperature of the muffle furnace burns off these residual organics, leaving behind a pure, porous sensing structure.

Relieving Internal Stresses

The deposition process introduces internal physical stresses within the sensing layer.

If left untreated, these stresses can cause the film to crack or delaminate over time, leading to sensor failure.

Thermal treatment relaxes these internal forces, ensuring the film remains continuous and structurally sound during long-term monitoring.

Microstructural Consistency

Reliable gas sensing depends on a stable crystal structure.

Annealing finalizes the microstructure of the sensing material, ensuring the grain size and porosity are consistent.

This stability is essential for ensuring signal repeatability, meaning the sensor will react the same way to the same gas concentration every time.

Understanding the Trade-offs

The Risk of Inadequate Heat

Skipping or shortening the annealing phase is a common cause of "drifting" sensor signals.

If the temperature is too low (below the target 400 °C), organic binders may linger, leading to false readings as they slowly off-gas during operation.

Furthermore, insufficient heat fails to relieve stress, resulting in microscopic cracks that alter resistance unpredictably.

The Importance of Controlled Atmosphere

Using a muffle furnace provides a specific benefit over open heating: a controlled thermal environment.

While some semiconductor processes require vacuum or inert atmospheres to prevent oxidation, gas sensing layers (which are often metal oxides) typically benefit from an air-atmosphere muffle furnace.

This environment aids in the complete oxidation of the material and the removal of organic contaminants, though precise temperature control is vital to avoid damaging the gold electrodes.

Making the Right Choice for Your Goal

While annealing is a standard requirement, the parameters define the outcome.

- If your primary focus is mechanical durability: Ensure the annealing cycle is long enough to fully relieve internal stresses, preventing the sensing film from peeling off the ceramic tube.

- If your primary focus is signal precision: Prioritize reaching the optimal temperature (e.g., 400 °C) to guarantee a strong ohmic contact and the complete removal of interfering organic solvents.

A gas sensor is only as good as its stability; proper annealing is the guarantee that the data it produces is real.

Summary Table:

| Key Benefit | Description | Importance for Sensors |

|---|---|---|

| Mechanical Adhesion | Fuses sensing layer to the ceramic tube | Prevents peeling and physical degradation |

| Ohmic Contact | Strengthens connection with gold electrodes | Ensures low-noise electrical signal transmission |

| Chemical Purity | Burns off residual organic solvents/binders | Eliminates baseline drift and false readings |

| Stress Relief | Relaxes internal physical stresses | Prevents micro-cracking and film delamination |

| Microstructure | Stabilizes grain size and porosity | Guarantees long-term signal repeatability |

Elevate Your Sensor Precision with KINTEK

Don't let signal drift or mechanical failure undermine your sensor manufacturing. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnace systems specifically designed for critical annealing and material stabilization.

Whether you need precise 400°C air-atmosphere control or customizable configurations for unique R&D needs, our equipment ensures your sensing layers achieve perfect adhesion and purity.

Contact us today to optimize your lab's high-temperature processes!

References

- Yuhong Zhang, Hang Liu. Au/ZnO/In<sub>2</sub>O<sub>3</sub> nanoparticles for enhanced isopropanol gas sensing performance. DOI: 10.1039/d3ra07507a

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What physical principles govern muffle furnace operation? Master Energy, Heat Transfer, and Control

- Why use vacuum muffle furnaces for nitrogen-doped biochar? Essential Atmosphere Control for Photocatalysis

- What role does a high-temperature muffle furnace play in the pre-calcination of PZT ceramics? Essential Synthesis Guide

- What types of heating elements are used in box type electric furnaces? Choose the Right Element for Your Lab

- What is the role of a muffle furnace in sintering nickel ferrite? Optimize Densification and Magnetic Performance

- What should be considered when choosing a muffle furnace manufacturer? Key Factors for Optimal Lab Performance

- What role does a laboratory high-temperature muffle furnace play in the treatment of highly contaminated waste glass?

- What are the advantages of energy efficiency and rapid heating/cooling in digital muffle furnaces? Boost Lab Productivity and Cut Costs