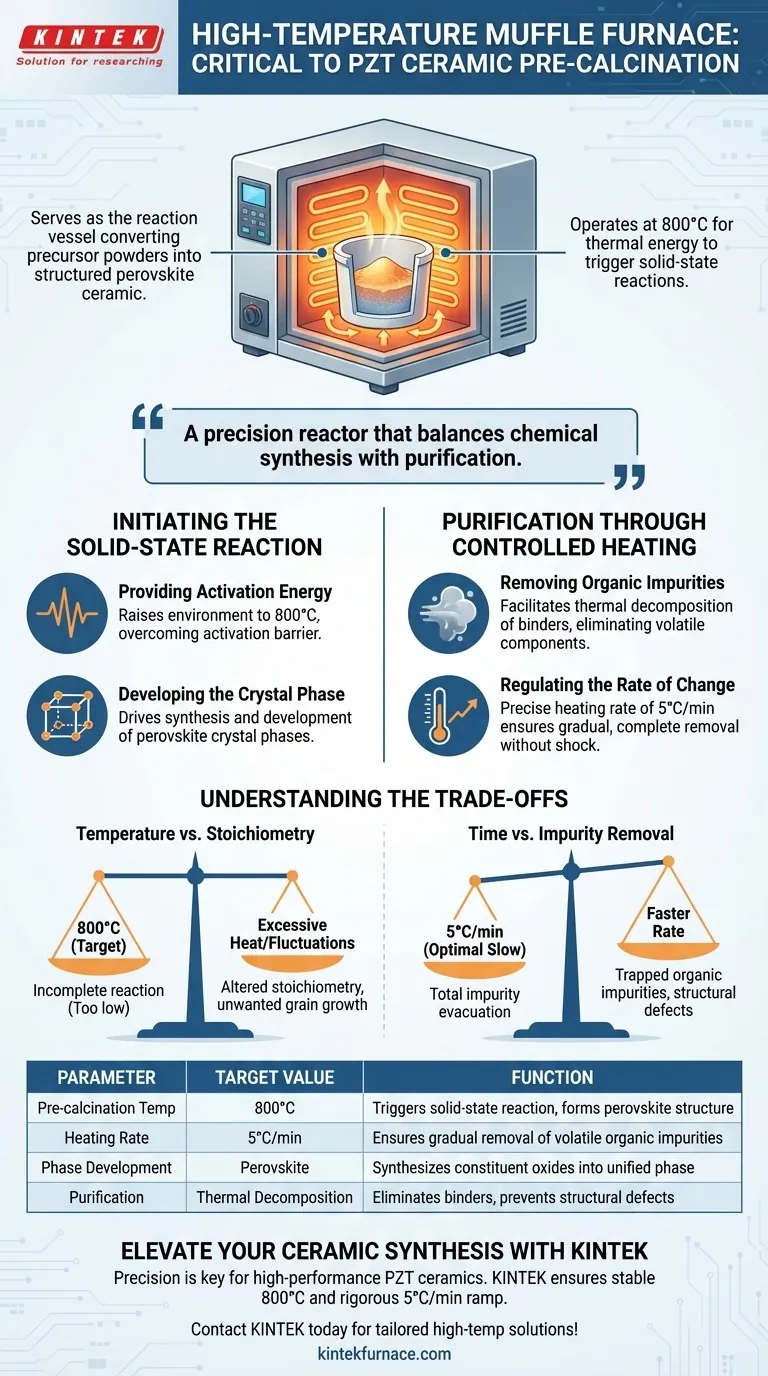

A high-temperature muffle furnace serves as the critical reaction vessel for transforming raw precursor powders into a structured ceramic material. Specifically, in the pre-calcination of Lead Zirconate Titanate (PZT), the furnace operates at 800°C to supply the thermal energy required to trigger solid-state reactions. This process converts a mixture of constituent oxides into the essential perovskite crystal structure while ensuring the complete removal of volatile impurities.

The muffle furnace acts as a precision reactor that balances chemical synthesis with purification. It drives the solid-state reaction to form the perovskite phase while controlling the thermal environment to prevent defects caused by trapped organic matter.

Initiating the Solid-State Reaction

The primary function of the furnace during this stage is to facilitate a phase change from a physical mixture to a chemical compound.

Providing Activation Energy

At room temperature, the constituent oxides in PZT precursors are merely mixed together.

The muffle furnace raises the environment to 800°C, the specific threshold required for pre-calcination.

This thermal energy overcomes the activation barrier, triggering a solid-state reaction that begins the actual formation of the perovskite structure.

Developing the Crystal Phase

The "pre-calcination" phase is not just about drying; it is about synthesis.

The heat drives the initial development of the desired crystal phases.

Without this high-temperature exposure, the material would remain a mix of separate oxides rather than becoming a unified PZT ceramic.

Purification Through Controlled Heating

Beyond synthesis, the furnace plays a vital role in purification, ensuring the material is chemically clean before further processing.

Removing Organic Impurities

Precursor powders often contain organic binders or impurities that must be eliminated.

The muffle furnace facilitates the thermal decomposition of these organics.

By maintaining a consistent high temperature, the furnace ensures these volatile components are fully burned off and evacuated from the material.

Regulating the Rate of Change

The speed at which the temperature rises is just as critical as the final temperature.

The process requires a precise heating rate of 5°C per minute.

This controlled ramp-up allows for the gradual and complete removal of impurities without shocking the material, ensuring a stable foundation for the crystal structure.

Understanding the Trade-offs

While the muffle furnace is essential, the parameters used involve inherent compromises that must be managed.

Temperature vs. Stoichiometry

The target temperature of 800°C is a specific balance point.

If the temperature is too low, the solid-state reaction will be incomplete, leaving unreacted oxides.

If uncontrolled, excessive heat or rapid fluctuations could potentially alter the stoichiometry or lead to unwanted grain growth before the final sintering stage.

Time vs. Impurity Removal

The heating rate of 5°C/min is relatively slow, extending the process time.

However, increasing this rate to save time risks trapping organic impurities inside the forming lattice.

Trapped impurities can lead to structural defects that compromise the final ceramic's performance.

Making the Right Choice for Your Process

To optimize the pre-calcination of PZT ceramics, you must align your furnace parameters with your specific material goals.

- If your primary focus is Phase Purity: Ensure your furnace can maintain a stable 800°C to guarantee the complete solid-state reaction of constituent oxides into the perovskite structure.

- If your primary focus is Defect Minimization: Prioritize precise control over the ramp rate, strictly adhering to 5°C/min to allow for the total evacuation of organic impurities.

By rigorously controlling the thermal environment, you establish the structural integrity required for high-performance PZT ceramics.

Summary Table:

| Parameter | Target Value | Function in PZT Pre-calcination |

|---|---|---|

| Pre-calcination Temp | 800°C | Triggers solid-state reaction to form perovskite structure |

| Heating Rate | 5°C/min | Ensures gradual removal of volatile organic impurities |

| Phase Development | Perovskite | Synthesizes constituent oxides into a unified ceramic phase |

| Purification | Thermal Decomposition | Eliminates binders and prevents structural defects |

Elevate Your Ceramic Synthesis with KINTEK

Precision is the foundation of high-performance PZT ceramics. At KINTEK, we understand that maintaining a stable 800°C and a rigorous 5°C/min ramp rate is non-negotiable for phase purity.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique lab high-temp needs. Whether you are focusing on perovskite phase development or defect minimization, our furnaces provide the thermal stability required for superior material integrity.

Ready to optimize your pre-calcination process? Contact KINTEK today for a tailored high-temperature solution!

Visual Guide

References

- Amna Idrees, Mohsin Saleem. Transforming Waste to Innovation: Sustainable Piezoelectric Properties of Pb(Ti<sub><b>0.52</b></sub>Zr<sub><b>0.48</b></sub>)O<sub><b>3</b></sub> with Recycled β-PbO Massicot. DOI: 10.1021/acsomega.5c00071

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What safety features are incorporated in muffle furnaces? Ensure Operator Protection and Equipment Safety

- What role does a high-temperature muffle furnace play in determining ash content? Expert Inorganic Analysis Guide

- What are the key benefits of using a muffle furnace? Achieve Precise, Contaminant-Free High-Temperature Control

- What function does a high-temperature muffle furnace serve during the calcination of GaN precursor resins? Purify GaN

- How does a muffle furnace facilitate the direct thermal polymerization of melamine? Master g-C3N4 Synthesis Today

- What are the primary functions of laboratory resistance furnaces in lead refining? Achieve 700°C Thermal Precision

- What are the benefits of using an electric furnace for home heating? Uncover the Safe, Efficient Solution

- What controls the temperature regulation in a muffle furnace? Master Precision with Advanced PID Controllers