When evaluating a new heating system, an electric furnace stands out for its exceptional efficiency and operational simplicity. Unlike fuel-burning alternatives, an electric furnace converts nearly every watt of electricity it draws directly into usable heat, achieving a 100% AFUE rating. This, combined with its inherent safety and quiet operation, makes it a compelling option for many homeowners.

The primary benefit of an electric furnace is its perfect conversion of electricity to heat. However, its true value depends on balancing this technical efficiency against the real-world cost of electricity in your specific region.

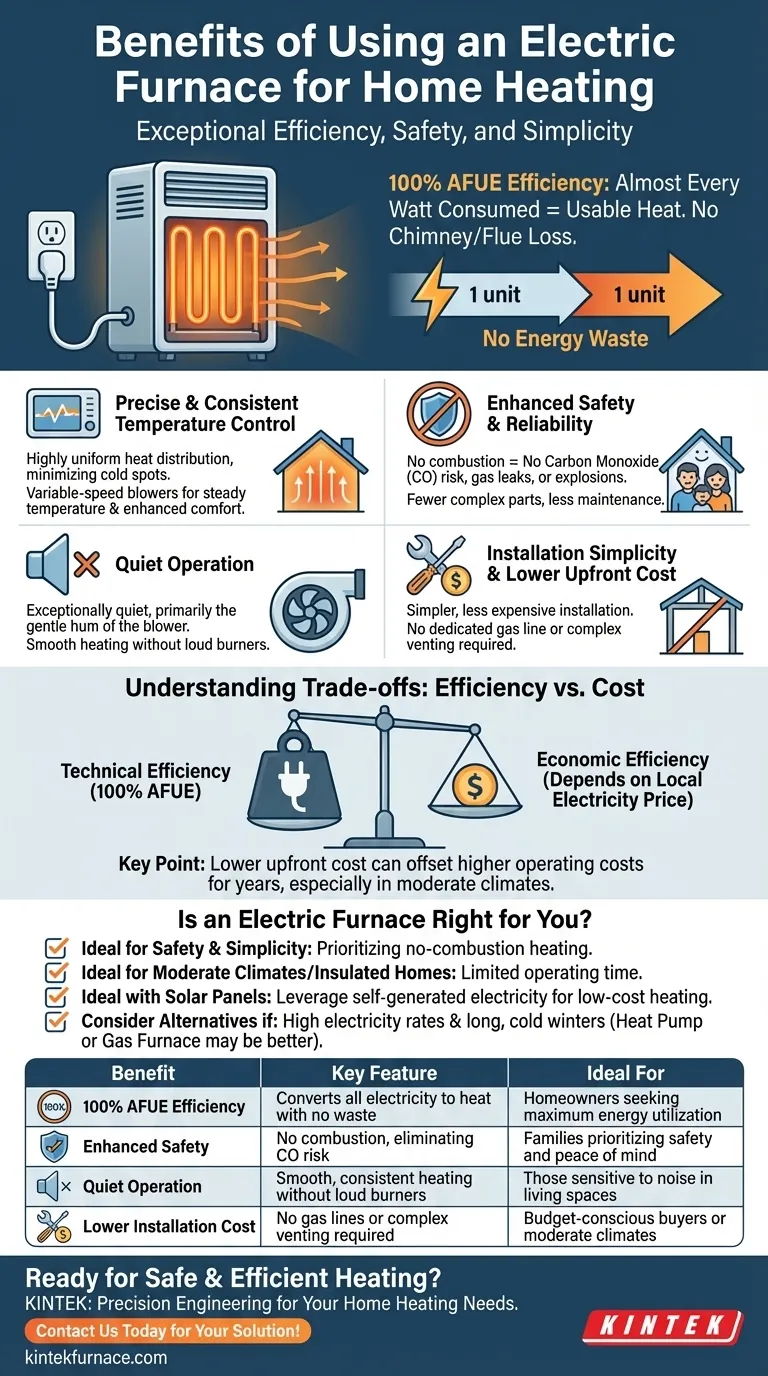

The Core Advantages of Electric Heating

Understanding the specific benefits of an electric furnace helps clarify its place in the modern home. Its design eliminates many of the complexities associated with traditional combustion heating.

Unmatched Energy Efficiency (100% AFUE)

An electric furnace has an Annual Fuel Utilization Efficiency (AFUE) of 100%. This means that for every dollar you spend on electricity to power the unit, you get one dollar's worth of heat.

There is no heat lost through a chimney or exhaust flue, a common point of energy waste in gas or oil furnaces. Every bit of energy consumed serves its primary purpose: warming your home.

Precise and Consistent Temperature Control

Electric heating elements allow for incredibly precise temperature regulation. This results in highly uniform heat distribution throughout your home, minimizing the cold spots often found with other systems.

Modern units featuring variable-speed blowers can further refine this process. They adjust airflow to maintain a steady temperature, avoiding the jarring on-off cycles of older systems and enhancing overall comfort.

Enhanced Safety and Reliability

The most significant safety advantage is the complete absence of combustion. An electric furnace does not burn fuel, which eliminates the risk of carbon monoxide (CO) poisoning, gas leaks, or explosions.

This simpler design also translates to greater reliability. With fewer complex mechanical parts like gas valves or heat exchangers that can crack, electric furnaces often require less maintenance and have a long operational lifespan.

Quiet Operation and Installation Simplicity

Without the noise of burners igniting and the roar of combustion, electric furnaces are known for their exceptionally quiet operation. The primary sound is the gentle hum of the blower fan distributing air.

Installation is also typically simpler and less expensive than for a gas furnace. There is no need for a dedicated gas line, and more importantly, no requirement for complex venting or chimney infrastructure.

Understanding the Trade-offs: Efficiency vs. Cost

While technically 100% efficient, an electric furnace is not automatically the most economical choice. True cost-effectiveness is a function of both efficiency and the price of the energy source.

The Efficiency Paradox

A 100% AFUE rating is a measure of conversion, not cost. If the price of electricity in your area is significantly higher than the price of natural gas, a 95% efficient gas furnace could still be cheaper to operate month-to-month.

The key is to differentiate between technical efficiency (how well it converts energy) and economic efficiency (how much it costs to run).

The Critical Role of Upfront Costs

A major advantage for electric furnaces is their lower purchase and installation price. The simpler technology and lack of need for gas lines or venting can save you thousands of dollars on the initial investment.

This lower upfront cost can offset higher operating costs for many years, especially in regions with moderate climates where the furnace runs less frequently.

Is an Electric Furnace Right for You?

Choosing the right furnace requires aligning the technology's strengths with your home, climate, and financial priorities.

- If your primary focus is the lowest possible long-term operating cost: An electric furnace may not be ideal in areas with high electricity rates and long, cold winters. A high-efficiency heat pump or gas furnace is often more economical.

- If your primary focus is safety and installation simplicity: The inherent safety of no-combustion heating and lower installation complexity make an electric furnace an outstanding choice.

- If you live in a moderate climate or a highly insulated home: An electric furnace is a strong contender, as its lower upfront cost is a significant benefit and its operating time will be limited.

- If you have or are planning to install solar panels: An electric furnace becomes a powerful choice, as it allows you to leverage your own self-generated electricity to heat your home at a very low cost.

Ultimately, an electric furnace offers a clean, safe, and reliable heating solution that excels in its simplicity and direct efficiency.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| 100% AFUE Efficiency | Converts all electricity to heat with no waste | Homeowners seeking maximum energy utilization |

| Enhanced Safety | No combustion, eliminating CO risk | Families prioritizing safety and peace of mind |

| Quiet Operation | Smooth, consistent heating without loud burners | Those sensitive to noise in living spaces |

| Lower Installation Cost | No gas lines or complex venting required | Budget-conscious buyers or moderate climates |

Ready to experience the safety and efficiency of an electric furnace? At KINTEK, we specialize in advanced thermal solutions for diverse applications. While our expertise in high-temperature furnaces for laboratories is unmatched, our commitment to precision engineering and reliable performance translates directly to residential heating needs. Let us help you find the perfect heating solution for your home. Contact us today to discuss your requirements!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation