At its core, a muffle furnace excels at providing a highly controlled, high-temperature environment free from contamination. The key benefits stem from its unique design, which isolates the sample being heated from the actual heating elements. This separation enables precise temperature uniformity, process purity, and operational safety for a wide range of scientific and industrial applications.

The true value of a muffle furnace is not simply its ability to get hot, but its capacity to deliver repeatable, pure, and uniform heating. This control is the foundation for reliable material testing, accurate chemical analysis, and consistent quality control.

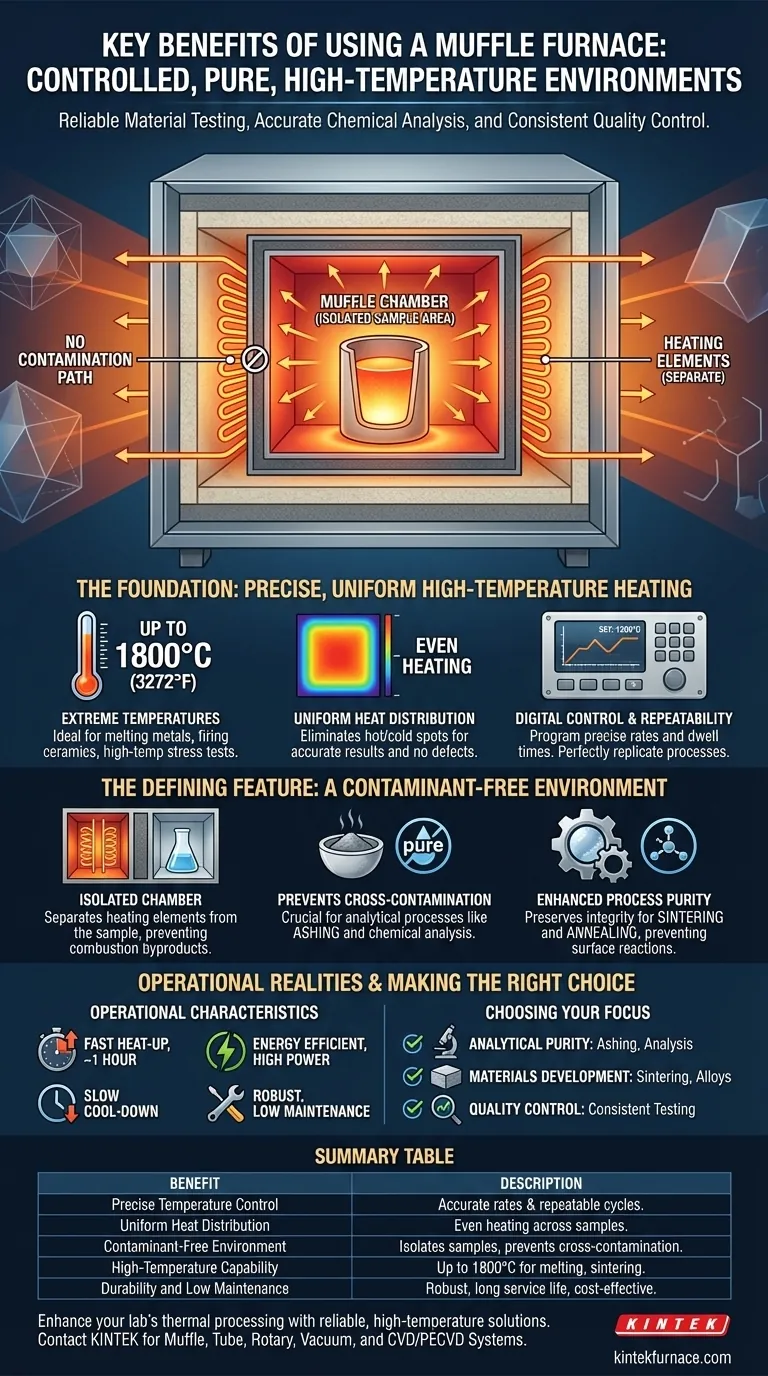

The Foundation: Precise, Uniform High-Temperature Heating

A muffle furnace is engineered for thermal accuracy. This precision is not a single feature but the result of several integrated design principles.

Achieving Extreme Temperatures

Muffle furnaces are built to operate at temperatures far beyond a standard oven, often ranging from 200°C up to 1800°C (3272°F). This capability is essential for processes like melting metals, firing ceramics, or performing high-temperature material stress tests.

The Importance of Uniformity

The enclosed chamber and advanced insulation ensure uniform heat distribution. Every part of your sample experiences the same temperature, eliminating hot or cold spots that could skew analytical results or create structural defects in materials.

Digital Control and Repeatability

Modern furnaces use sophisticated digital controllers. This allows you to program precise heating rates, target temperatures, and dwell times, ensuring that each thermal process can be perfectly replicated. This repeatability is critical for research and quality assurance.

The Defining Feature: A Contaminant-Free Environment

The most significant advantage of a muffle furnace comes from its name. The "muffle" is an inner chamber that isolates your sample from the heating elements and any byproducts of combustion.

What "Muffle" Means: Separating Heat from Sample

Imagine an oven where the heating coils are in a separate compartment from your food. That is the principle of a muffle furnace. The heat radiates through the muffle's walls to heat the sample, but no contaminants from the elements can enter the processing chamber.

Preventing Cross-Contamination

This isolation is crucial for analytical processes like ashing, where a sample is burned to determine its inorganic content. A muffle furnace ensures that the resulting ash is purely from the sample, not contaminated by flakes from the heating element or impurities from a gas flame.

Enhancing Process Purity

For material science applications like sintering or annealing, the clean environment prevents unwanted chemical reactions on the material's surface. This preserves the integrity and desired properties of the final product.

Understanding the Trade-offs and Operational Realities

While highly effective, it's important to understand the operational characteristics of a muffle furnace to use it effectively.

Heat-Up and Cool-Down Times

Thanks to powerful elements, many furnaces can reach maximum temperature in about an hour, improving laboratory throughput. However, the same excellent insulation that promotes energy efficiency also means that cool-down times can be slow. This must be factored into your workflow.

Energy Consumption

While modern designs are energy-efficient for the temperatures they achieve, they are still high-power devices. Their efficiency comes from superior insulation minimizing heat loss, not from low overall power draw during operation.

Durability and Maintenance

These furnaces are built to be robust, often using high-grade, heat-resistant materials that ensure a long service life. With low maintenance requirements, they are a cost-effective investment for long-term, heavy use in a lab or production environment.

Making the Right Choice for Your Process

The specific benefits of a muffle furnace align with distinct industrial and scientific goals.

- If your primary focus is analytical purity: The isolated, contaminant-free chamber is its most critical benefit, ensuring your sample's integrity for processes like gravimetric analysis or ashing.

- If your primary focus is materials development: The combination of extreme temperatures and uniform heating provides the precise control needed for heat treating, sintering ceramics, and creating new metal alloys.

- If your primary focus is quality control: The ability to program and repeat exact thermal cycles ensures that material testing is consistent and reliable every time.

Ultimately, a muffle furnace empowers you to take complete control over your high-temperature thermal processes.

Summary Table:

| Benefit | Description |

|---|---|

| Precise Temperature Control | Enables accurate heating rates and repeatable thermal cycles for consistent results. |

| Uniform Heat Distribution | Eliminates hot or cold spots, ensuring even heating across samples. |

| Contaminant-Free Environment | Isolates samples from heating elements, preventing cross-contamination. |

| High-Temperature Capability | Operates up to 1800°C, suitable for melting, sintering, and ashing. |

| Durability and Low Maintenance | Built with robust materials for long service life and cost-effectiveness. |

Ready to enhance your lab's thermal processing with reliable, high-temperature solutions? KINTEK specializes in advanced high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored furnace solutions can improve your material testing, chemical analysis, and quality control processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing