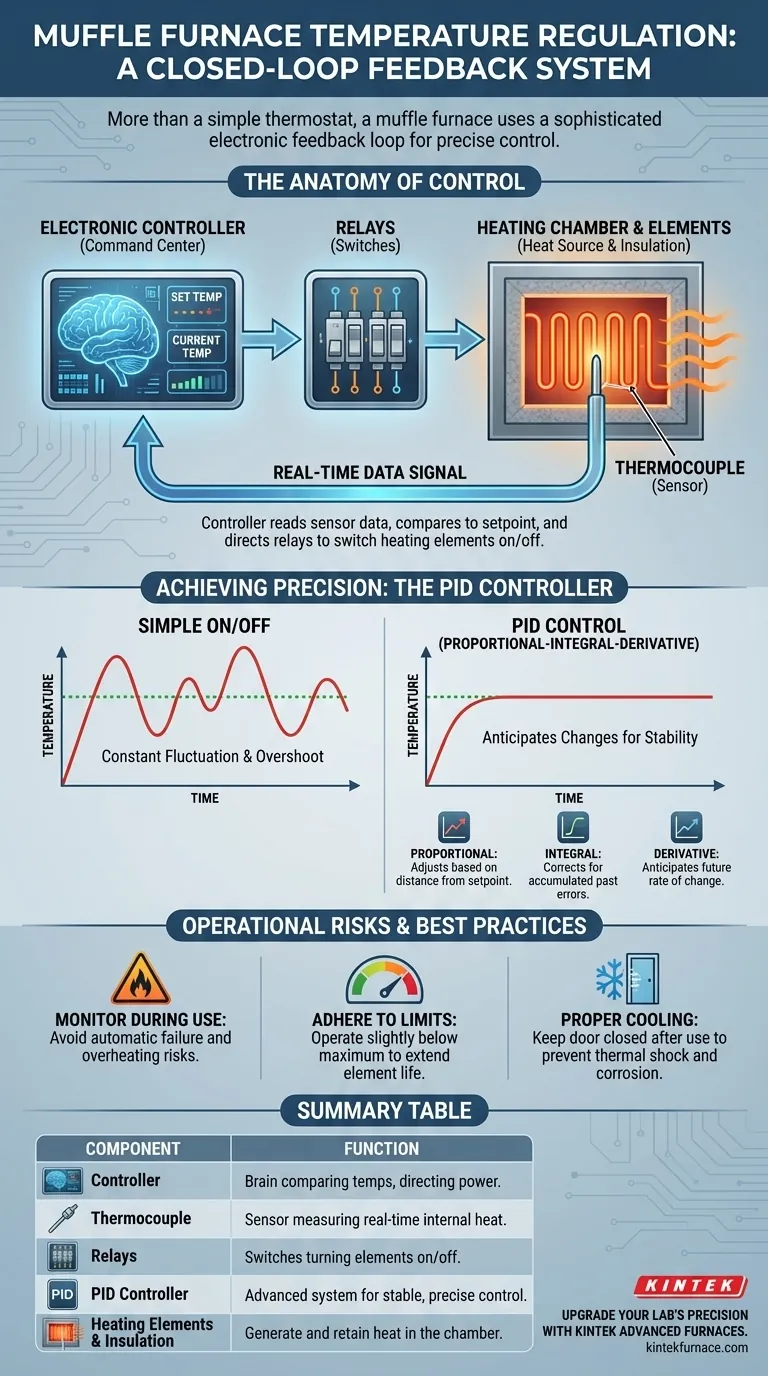

At the heart of a muffle furnace's operation is a sophisticated electronic feedback loop. Temperature is not passively managed; it is actively controlled by an electronic controller unit that reads data from a sensor, compares it to your desired temperature, and then directs relays to switch the main heating elements on or off to precisely maintain the setpoint.

A muffle furnace regulates temperature through a dynamic system, not a simple thermostat. A central controller uses a thermocouple to constantly measure the internal heat, then precisely switches the heating elements on and off via relays to maintain your setpoint with high accuracy. The most effective systems use a PID controller to prevent temperature overshooting and ensure stability.

The Anatomy of Temperature Regulation

A muffle furnace's ability to maintain stable, high temperatures depends on several interconnected components working in concert. This system is a classic example of a closed-loop control system.

The Controller: The Command Center

The electronic controller unit is the brain of the operation. It displays both the current temperature and the "set" temperature you have programmed. Its primary job is to decide when to apply or cut power to the heating elements.

The Thermocouple: The Sensor

A thermocouple is a robust sensor placed inside the heating chamber to measure the actual temperature. It sends a continuous signal back to the controller, providing the real-time data needed to make decisions.

The Relays: The Switches

Based on the controller's logic, electromagnetic relays act as heavy-duty switches. When the temperature is too low, the controller signals the relay to close, completing the circuit and turning the heating elements on. When the set temperature is reached, it signals the relay to open, cutting the power.

The Heating Elements and Insulation

The heating elements are the source of the heat, converting electrical energy into thermal energy. This heat is contained within the "muffle," or heating chamber, which is surrounded by high-grade insulation to minimize heat loss and maintain efficiency.

How the System Achieves Precision: The PID Controller

The quality of temperature regulation is defined by the intelligence of the controller. While simple controllers exist, the gold standard for laboratory and industrial applications is the PID controller.

Why Simple On/Off Isn't Enough

A basic controller operates like a home thermostat: it turns the heat on when it's too cold and off when it's too hot. This leads to constant temperature fluctuation, overshooting and undershooting the target temperature, which is unacceptable for sensitive processes.

How PID Achieves Stability

A PID (Proportional-Integral-Derivative) controller is far more advanced. It doesn't just react to the current temperature; it anticipates changes.

- Proportional: It adjusts the power based on how far the current temperature is from the setpoint.

- Integral: It corrects for small, steady-state errors by considering how long the temperature has been off-target.

- Derivative: It anticipates future temperature by looking at the rate of change, dampening the power as it approaches the setpoint to prevent overshooting.

This three-pronged approach allows the furnace to reach the target temperature quickly and hold it with exceptional stability.

Understanding the Trade-offs and Operational Risks

While highly effective, the temperature control system requires proper handling to ensure safety and longevity. Mismanagement is the most common cause of equipment failure.

Risk of Overheating and Control Failure

Always monitor the furnace during operation. Although rare, an automatic control failure (like a stuck relay) can cause the furnace to heat uncontrollably. This can burn out the heating elements and create a significant safety hazard.

The Importance of Operating Limits

Never set the furnace temperature above its specified maximum limit. Doing so will drastically shorten the life of the heating elements and can cause permanent damage. For longevity, operate slightly below the furnace's absolute maximum temperature.

Protecting the Furnace After Use

After a process is complete, cut the power but keep the furnace door closed until it has cooled considerably. Opening the door while the chamber is hot can cause a thermal shock and allows moisture from the air to enter, which can corrode the furnace chamber lining over time.

How to Apply This to Your Process

Understanding the control system empowers you to select the right equipment and operate it effectively. Your primary goal will determine your main point of focus.

- If your primary focus is high-precision thermal processing: Prioritize a furnace with a modern PID (Proportional-Integral-Derivative) controller for maximum temperature stability.

- If your primary focus is safety and equipment longevity: Strictly adhere to the manufacturer's maximum temperature limits and implement proper startup and shutdown procedures.

By understanding these control principles, you move from simply using the furnace to truly mastering its capabilities.

Summary Table:

| Component | Function |

|---|---|

| Electronic Controller | Brain that compares set and actual temperatures, directing power |

| Thermocouple | Sensor measuring real-time temperature inside the chamber |

| Relays | Switches that turn heating elements on/off based on controller signals |

| PID Controller | Advanced system using proportional, integral, and derivative actions for stability |

| Heating Elements & Insulation | Generate and retain heat within the muffle chamber |

Upgrade your lab's precision and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure solutions tailored to your unique experimental needs, delivering superior temperature control and durability. Contact us today to discuss how our products can enhance your thermal processing and ensure long-term reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis