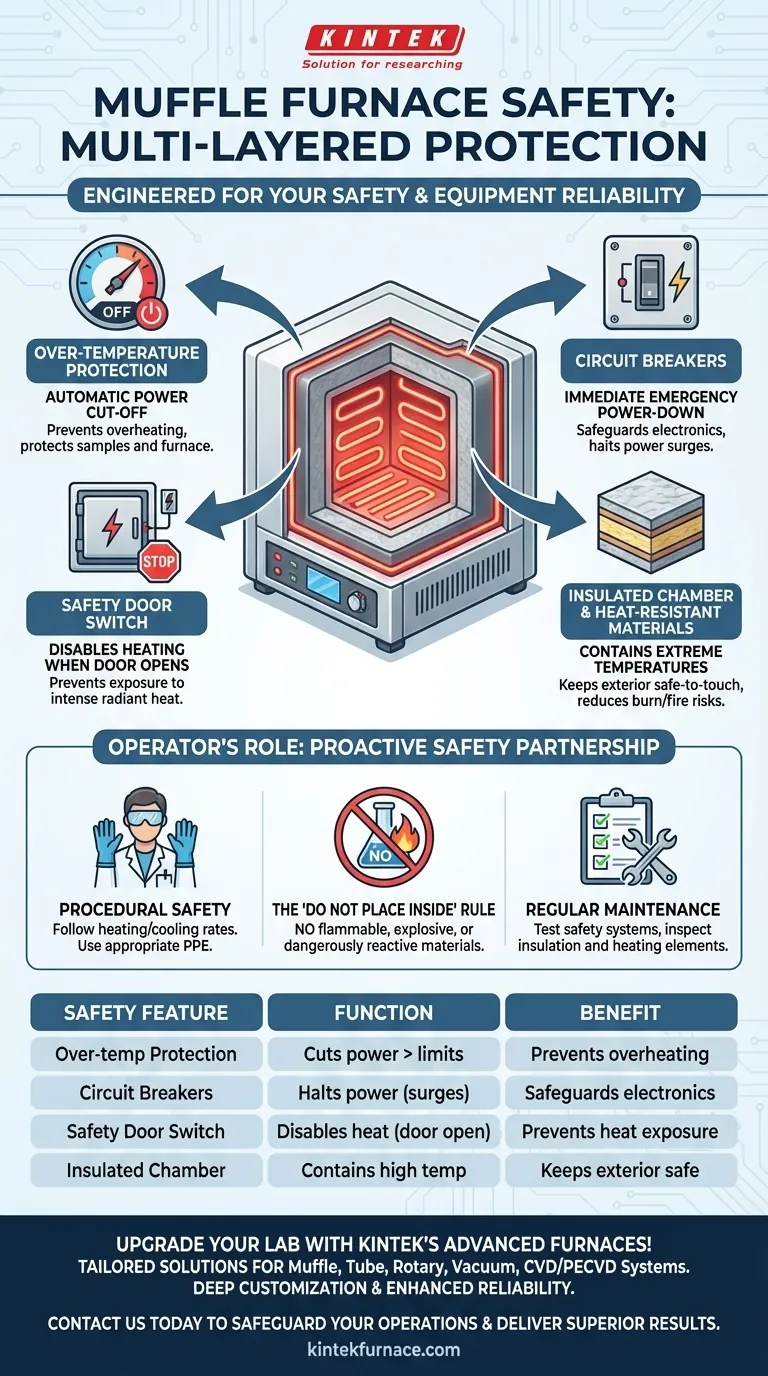

Modern muffle furnaces are engineered with a multi-layered safety system. They integrate active electrical safeguards like over-temperature protection and circuit breakers with passive physical barriers, such as heavily insulated chambers and safety door switches. These features work in concert to protect the equipment from damage and, most importantly, to ensure the operator remains safe from the extreme internal temperatures.

True operational safety is a partnership between the machine's robust design and the operator's vigilance. Understanding how the furnace’s built-in protections function is the first step toward preventing high-temperature accidents and ensuring reliable results.

Core Safety Mechanisms: How the Furnace Protects Itself and You

A muffle furnace's safety is not based on a single feature but on several independent systems that create redundant layers of protection. These can be broken down into electrical, mechanical, and thermal controls.

Preventing Overheating and Thermal Runaway

The most fundamental risk is the furnace exceeding its set temperature. Over-temperature protection is a critical, often secondary, control system that automatically cuts power to the heating elements if the primary controller fails and the temperature rises above a safe maximum.

This prevents damage to the furnace, the sample, and the surrounding environment. It works alongside the main programmable temperature controller, which ensures predictable and stable heating cycles.

Electrical Safeguards

Every muffle furnace is equipped with circuit breakers. These devices serve a dual purpose: they protect the internal electronics from power surges and short circuits, and they act as a manual, immediate emergency power-down switch in case of malfunction.

This provides a definitive way to halt the operation instantly if an unsafe condition is observed.

Operator Protection at the Door

A safety door switch is a simple but vital mechanical interlock. This switch automatically cuts power to the heating elements the moment the furnace door is opened.

This prevents the operator from being accidentally exposed to the chamber's intense radiant heat and any potentially hazardous atmospheres that may have been generated during the process.

Containing the Heat: Insulation and Construction

The furnace's body is built from heat-resistant materials and features a thick, insulated chamber. This design is essential for containing temperatures that can exceed 1000°C (1832°F).

This heavy insulation ensures the external shell of the furnace remains at a safe-to-touch temperature, protecting operators from burns and reducing the risk of igniting nearby materials.

Understanding Operator Responsibilities and Limitations

While a furnace is designed for safety, its features have limits. The operator plays an indispensable role in maintaining a safe work environment.

Built-in Features vs. Procedural Safety

The furnace's safety systems are primarily reactive. Alarms, auto-shutoffs, and circuit breakers activate after a fault has occurred. Proactive safety depends entirely on correct operational procedures.

This includes following specified heating and cooling rates, using appropriate personal protective equipment (PPE), and never leaving the unit unattended for excessive periods during critical processes.

The "Do Not Place Inside" Rule

A furnace's safety features are designed to manage thermal and electrical risks, not chemical ones. They cannot contain an explosion or a volatile chemical reaction.

It is absolutely critical that no flammable, explosive, or dangerously reactive materials are ever placed inside the furnace. Likewise, flammable materials should never be stored near the unit.

Why Maintenance is a Safety Function

Safety systems are only reliable if they are maintained. A faulty door switch or compromised insulation degrades the furnace's fundamental protective layers.

Regularly testing safety systems, inspecting the integrity of the chamber insulation, and checking heating elements for wear are not just maintenance tasks—they are critical safety procedures.

Making the Right Choice for Your Lab

To ensure maximum safety, align your procedures and purchasing decisions with your primary goals.

- If your primary focus is routine operation: Regularly verify that the safety door switch functions correctly and always keep the area around the furnace clear of flammables.

- If your primary focus is purchasing a new furnace: Prioritize models with certified over-temperature protection and a clearly accessible emergency shut-off or circuit breaker.

- If your primary focus is long-term reliability: Implement a formal maintenance schedule that includes documented checks of the insulation, heating elements, and all safety circuits.

A well-maintained furnace, operated with knowledge and discipline, is an exceptionally safe and powerful tool for your work.

Summary Table:

| Safety Feature | Function | Benefit |

|---|---|---|

| Over-temperature Protection | Cuts power if temperature exceeds safe limits | Prevents overheating, protects samples and furnace |

| Circuit Breakers | Halts power during surges or emergencies | Safeguards electronics, allows immediate shutdown |

| Safety Door Switch | Disables heating when door opens | Prevents operator exposure to heat and hazards |

| Insulated Chamber | Contains high temperatures internally | Keeps exterior safe, reduces burn and fire risks |

| Heat-resistant Materials | Withstands extreme heat | Ensures durability and long-term safety |

Upgrade your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing reliability and protection. Contact us today to discuss how our furnaces can safeguard your operations and deliver superior results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis