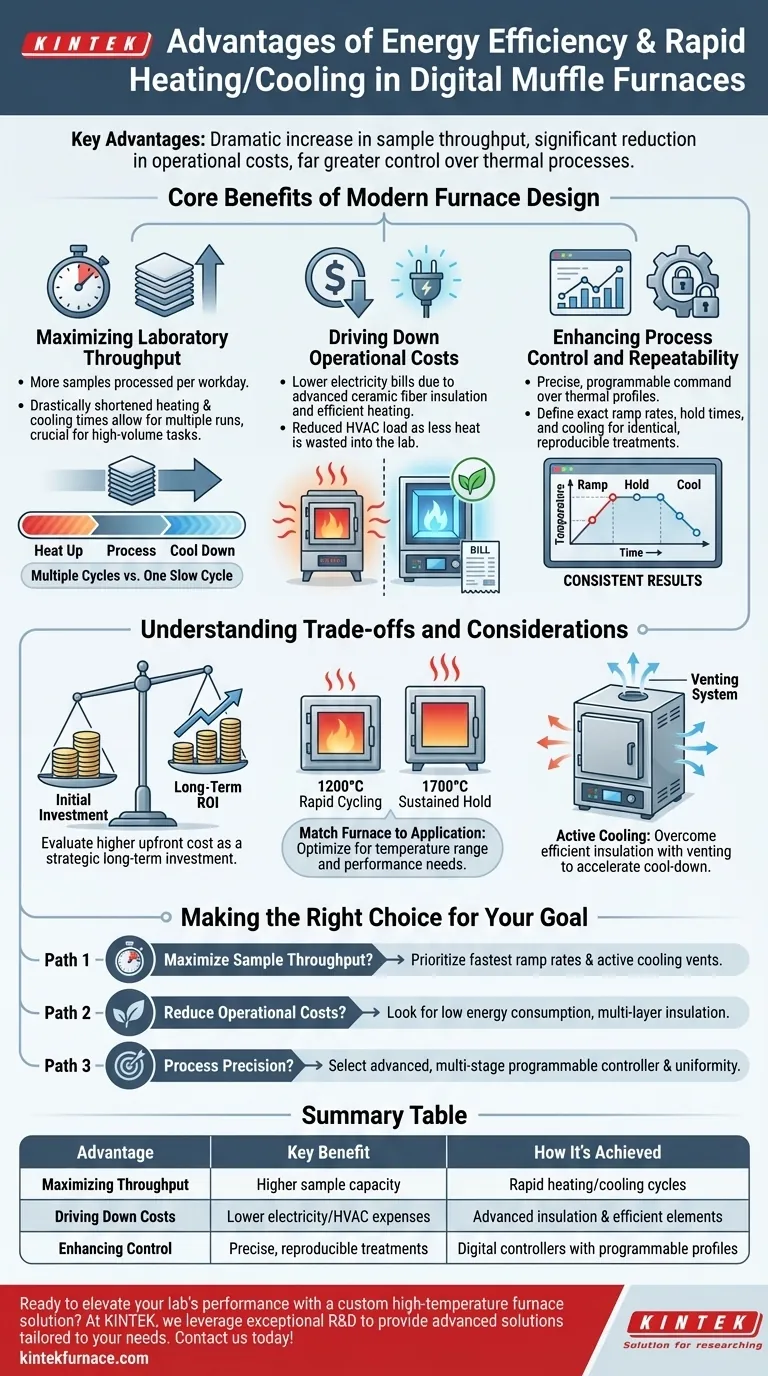

The key advantages are a dramatic increase in sample throughput, a significant reduction in operational costs, and far greater control over thermal processes. Modern digital muffle furnaces achieve these benefits by combining highly efficient insulation with advanced digital controllers, allowing for rapid heating and cooling cycles that older models cannot match.

The decision to invest in a modern digital muffle furnace is not merely an equipment upgrade. It is a strategic choice to improve laboratory efficiency, lower long-term energy expenditures, and enhance the precision and repeatability of critical thermal applications.

The Core Benefits of Modern Furnace Design

The value of a modern digital muffle furnace extends beyond its basic function of heating materials. The efficiency and speed of its thermal cycling create tangible advantages in productivity, cost, and quality.

Advantage 1: Maximizing Laboratory Throughput

The most immediate benefit of rapid heating and cooling is the ability to process more samples in a single workday.

By drastically shortening the time required for the furnace to reach its target temperature and cool down safely, operators can complete multiple runs in the time it would take for one cycle in an older, slower unit.

This increased throughput is especially critical for high-volume tasks like water quality testing, environmental sample preparation, and routine quality assurance checks.

Advantage 2: Driving Down Operational Costs

Energy efficiency directly translates to lower electricity bills. Modern furnaces use advanced ceramic fiber insulation and intelligently designed heating elements to minimize heat loss.

This means more energy is directed at heating your sample and less is wasted into the surrounding lab space.

A secondary benefit is a reduced load on your facility's HVAC system, which no longer has to work as hard to compensate for a constantly radiating heat source, further lowering overall energy costs.

Advantage 3: Enhancing Process Control and Repeatability

Digital controllers provide precise, programmable command over the entire thermal profile. This is a significant leap from the analog dials of older equipment.

Operators can define exact ramp rates, hold times, and cooling profiles, ensuring that every sample undergoes the identical thermal treatment.

This level of repeatability is essential for sensitive applications like thermogravimetric analysis (TGA) and for developing consistent material properties through processes like quenching.

Understanding the Trade-offs and Considerations

While the benefits are clear, selecting the right furnace requires a balanced understanding of the initial investment and the specific requirements of your application.

Initial Investment vs. Long-Term ROI

A state-of-the-art digital muffle furnace will have a higher upfront cost than a basic, older model.

This cost should be evaluated as a long-term investment. The savings from reduced energy consumption and the financial upside of increased productivity will often provide a clear return on investment over the furnace's lifespan.

Matching the Furnace to the Application

Not all furnaces are created equal. A furnace optimized for rapid cycling up to 1200°C may not be the best or most cost-effective choice for an application that requires sustained holds at 1700°C.

It is crucial to match the furnace's temperature range and performance characteristics to your specific needs, whether it's for general lab work, industrial production, or specialized materials research. Custom-built furnaces can be an option for unique requirements.

The Role of Chamber Design

Rapid cooling is not just about turning the power off. High-efficiency insulation that holds heat in can slow down the natural cooling process.

To overcome this, many modern furnaces incorporate features like a venting system or even forced-air cooling to actively accelerate the cool-down phase, ensuring you get the full benefit of a rapid cycle.

Making the Right Choice for Your Goal

Your specific priorities should guide your selection process. Consider what aspect of performance will have the greatest impact on your work.

- If your primary focus is maximizing sample throughput: Prioritize furnaces with the fastest documented ramp rates and features like active cooling vents to shorten the full cycle time.

- If your primary focus is reducing operational costs: Look for models that specifically advertise low energy consumption, featuring multi-layered ceramic fiber insulation and energy-efficient elements.

- If your primary focus is process precision for research or QA: Select a furnace with an advanced, multi-stage programmable digital controller and documented temperature uniformity within the chamber.

Choosing the right furnace is about aligning the technology's capabilities with your strategic operational goals.

Summary Table:

| Advantage | Key Benefit | How It's Achieved |

|---|---|---|

| Maximizing Laboratory Throughput | Higher sample processing capacity | Rapid heating and cooling cycles |

| Driving Down Operational Costs | Lower electricity and HVAC expenses | Advanced insulation and efficient heating elements |

| Enhancing Process Control and Repeatability | Precise, reproducible thermal treatments | Digital controllers with programmable profiles |

Ready to elevate your lab's performance with a custom high-temperature furnace solution?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're focused on maximizing throughput, reducing costs, or enhancing precision, we have the expertise to help.

Contact us today to discuss how our furnaces can drive efficiency and innovation in your laboratory!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization