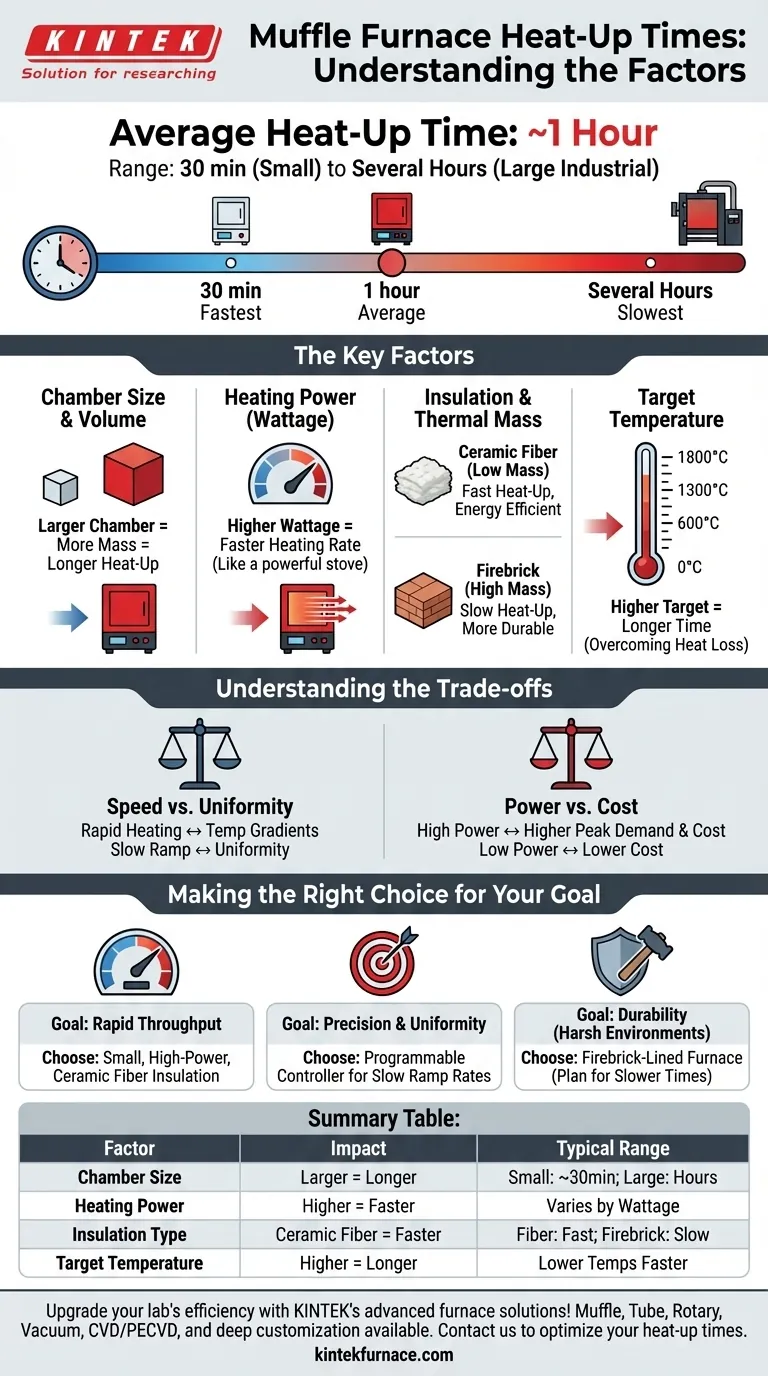

On average, a muffle furnace takes about one hour to reach its maximum temperature. However, this is a general guideline; the actual time can range from as little as 30 minutes for small laboratory models to several hours for large industrial units, depending on a few critical design factors.

The time a muffle furnace takes to heat up is not a fixed number, but a direct consequence of its design. Understanding the interplay between chamber size, heating power, and insulation type is the key to predicting and managing its performance for your specific application.

The Key Factors That Dictate Heat-Up Time

The "one hour" average is a useful starting point, but the true performance is governed by the furnace's fundamental engineering.

Chamber Size and Volume

A larger internal chamber requires significantly more energy to bring the entire volume and its surrounding insulation up to temperature. This is a simple matter of physics; more mass requires more thermal energy.

A small, benchtop lab furnace with a volume of a few liters will naturally heat up much faster than an industrial furnace with a large chamber designed for bulk processing.

Heating Element Power (Wattage)

The power of the heating elements, measured in watts (W) or kilowatts (kW), is the engine driving the temperature rise. A higher wattage means the furnace can generate heat more quickly.

Think of it like boiling water: a more powerful stove burner will bring a pot of water to a boil much faster than a weaker one. High-power furnaces are designed for rapid cycling.

Insulation and Thermal Mass

This is one of the most critical but often overlooked factors. The type and thickness of the insulation determine both how quickly the furnace heats up and how efficiently it holds that heat.

Modern furnaces often use lightweight ceramic fiber insulation. It has low thermal mass, meaning it absorbs very little heat itself, allowing most of the energy to heat the chamber and its contents. This results in faster heat-up and cool-down times.

Older or more specialized furnaces may use dense firebrick. While extremely durable, firebrick has high thermal mass. A significant amount of energy is spent just heating the bricks, leading to much slower heat-up times.

Target Temperature

A furnace will reach a lower operating temperature, such as 1000°C, much faster than its absolute maximum rated temperature, like 1800°C.

As the furnace gets hotter, the rate of heat loss to the surrounding environment increases dramatically. The final push from a high temperature to the maximum temperature requires overcoming this significant, constant heat loss, which can take a disproportionately long time.

Understanding the Trade-offs

A faster heat-up time is not always the best or only goal. The optimal choice depends on balancing speed with other process requirements.

Speed vs. Temperature Uniformity

Rapid heating can sometimes create temperature gradients, where some parts of the chamber are hotter than others. For sensitive materials or precise chemical reactions, a slower, controlled ramp rate is often programmed to ensure perfect temperature uniformity.

Power vs. Operational Cost

A furnace with high-power elements will heat up faster but will also have a higher peak electricity demand. This increases operational costs and may require more robust electrical infrastructure.

Insulation: Fiber vs. Brick

Lightweight ceramic fiber enables speed and energy efficiency but can be more susceptible to mechanical damage and chemical attack. Dense firebrick is exceptionally rugged and resistant to wear but at the cost of much slower thermal cycling and lower energy efficiency.

Making the Right Choice for Your Goal

To select or operate a furnace effectively, align its characteristics with your primary objective.

- If your primary focus is rapid throughput and testing: Choose a smaller, high-power furnace with lightweight ceramic fiber insulation for the fastest possible heat-up and cool-down cycles.

- If your primary focus is process precision and uniformity: Prioritize a furnace with a sophisticated digital controller that allows you to program slow, deliberate ramp rates, regardless of its maximum heating speed.

- If your primary focus is durability in a harsh industrial environment: A firebrick-lined furnace may be the better choice, but you must plan your workflow around its inherently slower heating and cooling times.

By understanding these core principles, you can move from asking "how long" to controlling precisely how your furnace performs for your specific needs.

Summary Table:

| Factor | Impact on Heat-Up Time | Typical Range |

|---|---|---|

| Chamber Size | Larger size increases time | Small lab units: ~30 min; Large industrial: several hours |

| Heating Power | Higher power reduces time | Varies by wattage; high-power models heat faster |

| Insulation Type | Low thermal mass (e.g., ceramic fiber) reduces time | Ceramic fiber: fast; Firebrick: slow |

| Target Temperature | Higher temperatures increase time | Lower temps (e.g., 1000°C) faster than max (e.g., 1800°C) |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can optimize your heat-up times and overall performance!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production