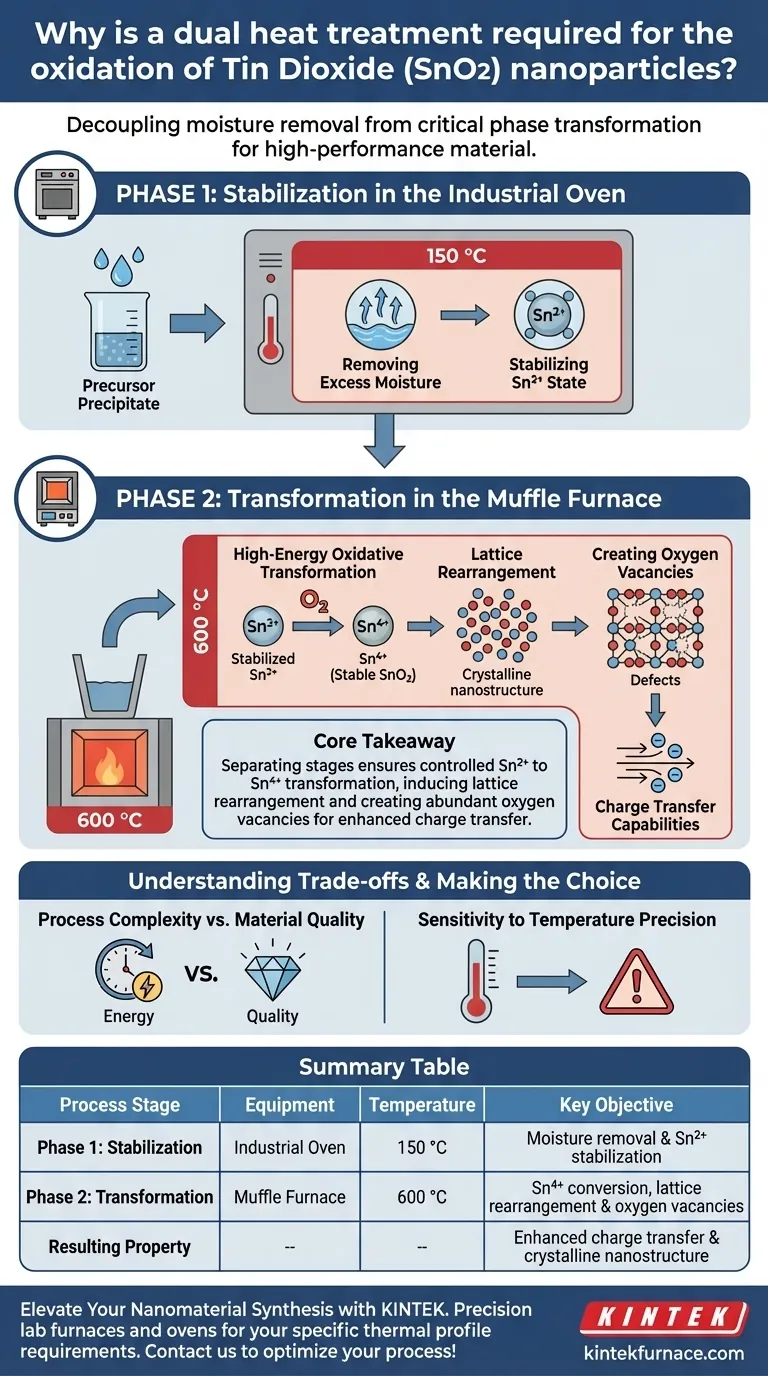

The dual heat treatment process allows you to decouple moisture removal from the critical phase transformation. An industrial oven is utilized first to dry and stabilize the precursor at lower temperatures, while a muffle furnace is required subsequently to provide the high thermal energy needed to convert the material's oxidation state and crystal structure.

Core Takeaway By separating thermal processing into two distinct stages, you ensure the controlled transformation of Tin from the Sn2+ state to the Sn4+ state. This precise control induces lattice rearrangement and creates abundant oxygen vacancies, which are essential for enhancing the material's charge transfer capabilities.

Phase 1: Stabilization in the Industrial Oven

The first stage of the process is strictly preparatory. It prepares the physical state of the material to endure the harsh conditions of the second stage.

Removing Excess Moisture

The initial heating is performed at 150 °C.

The primary goal here is the removal of excess moisture from the precipitate. Eliminating water content early prevents rapid vaporization during the high-temperature phase, which could damage the nanostructure.

Stabilizing the Oxidation State

Beyond simple drying, this phase plays a chemical role.

Heating at this lower temperature stabilizes the Sn2+ state. This ensures the precursor is chemically uniform before the oxidative transformation begins.

Phase 2: Transformation in the Muffle Furnace

Once the precursor is dried and stabilized, the muffle furnace is used to engineer the material's final properties through prolonged annealing.

High-Energy Oxidative Transformation

The muffle furnace operates at a much higher temperature of 600 °C.

This high thermal energy is required to drive the oxidation reaction. It converts the stabilized Sn2+ completely into the Sn4+ state, which is the stable form of Tin Dioxide (SnO2).

Lattice Rearrangement

Crystallinity is established during this phase.

The prolonged exposure to 600 °C induces lattice rearrangement. The atoms align into a highly ordered crystalline nanostructure, which is critical for the material's durability and performance.

Creating Oxygen Vacancies

The specific conditions of this heat treatment do more than just align atoms.

The process engineers defects known as oxygen vacancies within the crystal lattice. These vacancies are not errors; they are desired features that significantly improve the material's electronic properties.

Enhancing Charge Transfer

The ultimate output of this two-step process is functional efficiency.

The presence of abundant oxygen vacancies directly enhances charge transfer capabilities. Without the high-temperature annealing in the muffle furnace, the material would lack the electronic structure necessary for high-performance applications.

Understanding the Trade-offs

While a dual heat treatment produces superior SnO2 nanoparticles, it introduces specific operational considerations.

Process Complexity vs. Material Quality

This approach increases processing time and energy consumption compared to a single-step calcination.

However, skipping the low-temperature stabilization can lead to structural collapse due to rapid water evaporation. Conversely, skipping the high-temperature anneal results in poor crystallinity and insufficient oxygen vacancies.

Sensitivity to Temperature Precision

The transition from Sn2+ to Sn4+ is sensitive.

Inaccuracies in the muffle furnace temperature (deviating from 600 °C) can result in incomplete oxidation or excessive grain growth, degrading the surface area and catalytic activity of the nanostructures.

Making the Right Choice for Your Goal

The dual-step method is not arbitrary; it is a requirement for high-performance SnO2.

- If your primary focus is precursor preparation: Prioritize the industrial oven phase to ensure complete moisture removal and Sn2+ stabilization, preventing structural defects later.

- If your primary focus is electronic performance: Ensure the muffle furnace maintains a precise 600 °C profile to maximize oxygen vacancy formation and optimize charge transfer.

Mastering this thermal profile is the key to unlocking the full potential of Tin Dioxide nanostructures.

Summary Table:

| Process Stage | Equipment | Temperature | Key Objective |

|---|---|---|---|

| Phase 1: Stabilization | Industrial Oven | 150 °C | Moisture removal & Sn2+ state stabilization |

| Phase 2: Transformation | Muffle Furnace | 600 °C | Sn4+ conversion, lattice rearrangement & oxygen vacancies |

| Resulting Property | - | - | Enhanced charge transfer & crystalline nanostructure |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the difference between a failed precursor and high-performance Tin Dioxide. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your specific thermal profile requirements.

Whether you need an industrial oven for stabilization or a high-temp furnace for critical lattice rearrangement, our equipment ensures uniform heating and exact temperature control for your laboratory's unique needs.

Ready to optimize your heat treatment process? Contact us today to find the perfect furnace solution!

Visual Guide

References

- Soumya Mishra, Prangya Ranjan Rout. Construction of a novel ternary synergistic CuFe <sub>2</sub> O <sub>4</sub> –SnO <sub>2</sub> -rGO heterojunction for efficient removal of cyanide from contaminated water. DOI: 10.1039/d4ra02217c

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What hardware characteristics are required for a reactor system to support a three-step redox process in chemical looping?

- Why is staged temperature control required in industrial air drying ovens for carbon nanofibers? Key Safety Insights

- What is the purpose of applying a hexagonal Boron Nitride (h-BN) coating to graphite? Enhance Purity & Tool Longevity

- What is the primary function of a laboratory electric drying oven in sample prep? Ensure Pure, Grinder-Ready Powders

- What is the role of sintering in CsPbBr3-SiO2 preparation? Unlock Ultra-Stability with Precise Thermal Sealing

- What is the function of a flash furnace in sludge treatment? Essential Thermal Preparation for Phosphorus Recovery

- Why Use a Vacuum Drying Oven for Ti3C2 MXene@NiS or Co4S3? Prevent Oxidation and Preserve Catalyst Integrity

- How does a constant temperature and humidity curing chamber contribute to alkali-activated material performance?