High-temperature sintering acts as a critical sealing mechanism that physically alters the protective silica shell. By subjecting the material to temperatures between 600 °C and 900 °C in a muffle or tube furnace, the process induces the controlled collapse of mesoporous channels, effectively locking the perovskite nanocrystals inside a dense, impenetrable matrix.

The core value of this thermal treatment is the transformation of the host material from a porous structure into a solid shield. This "pore-sealing" technique is the defining factor that grants the composite exceptional resistance to harsh chemical agents, such as strong acids.

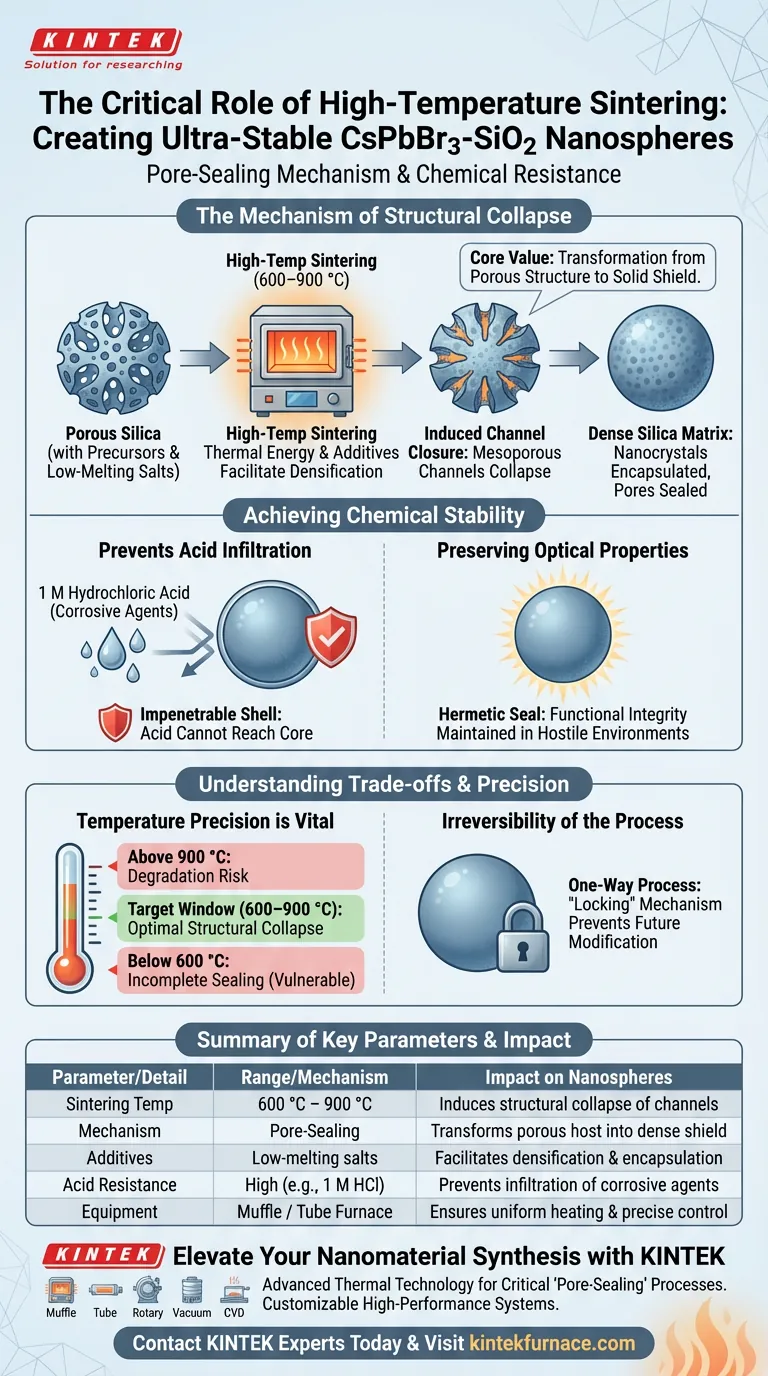

The Mechanism of Structural Collapse

Induced Channel Closure

The primary function of the furnace is to provide the thermal energy required to alter the physical structure of the silica.

When the temperature rises to the 600–900 °C range, the mesoporous channels in the silica begin to collapse. This is a deliberate structural failure that eliminates the pathways connecting the internal nanocrystals to the outside environment.

The Role of Low-Melting-Point Salts

This process is not achieved by heat alone; it relies on specific chemical additives.

The silica is impregnated with perovskite precursors and low-melting-point salts, such as potassium carbonate. These salts facilitate the densification process, ensuring the silica closes tightly around the nanocrystals without destroying them.

Creation of a Dense Matrix

The result of this sintering is a fundamental change in material density.

The originally porous framework transforms into a dense silica matrix. This completely encapsulates the CsPbBr3 nanocrystals, isolating them from external variables.

Achieving Chemical Stability

Preventing Acid Infiltration

The most significant benefit of this sealed architecture is resistance to corrosion.

Because the pores are physically closed, corrosive agents like 1 M hydrochloric acid cannot penetrate the shell. The acid is unable to reach the vulnerable perovskite core, rendering the composite ultra-stable.

Preserving Optical Properties

By creating a hermetic seal, the sintering process preserves the integrity of the nanocrystals.

The dense silica acts as a permanent barrier. This ensures that the functional properties of the perovskite are maintained even when the material is deployed in hostile environments.

Understanding the Trade-offs

Temperature Precision is Vital

While high heat is necessary, the range must be strictly controlled.

Sintering below 600 °C may fail to fully collapse the pores, leaving the nanocrystals vulnerable to chemical attack. Conversely, excessive heat beyond the target window could potentially degrade the perovskite components despite the silica protection.

Irreversibility of the Process

Once the mesoporous channels are collapsed, the process is irreversible.

This "locking" mechanism is excellent for stability but prevents any further modification of the internal nanocrystals. You must ensure the precursors are correctly impregnated before the sintering step begins.

Making the Right Choice for Your Project

To ensure you achieve the desired stability for your CsPbBr3-SiO2 nanospheres, consider the following technical focus points:

- If your primary focus is maximum chemical resistance: Ensure your sintering temperature reaches the upper effective range (near 900 °C) to guarantee the complete elimination of all mesoporous channels.

- If your primary focus is process consistency: Utilize a tube furnace or muffle furnace with precise temperature control to maintain the environment strictly between 600 °C and 900 °C, preventing thermal shock or incomplete sealing.

The ultimate success of this preparation method relies on using heat not just to dry the material, but to physically densify the silica into a permanent protective shield.

Summary Table:

| Parameter | Range/Detail | Impact on Nanospheres |

|---|---|---|

| Sintering Temp | 600 °C – 900 °C | Induces structural collapse of mesoporous channels |

| Mechanism | Pore-Sealing | Transforms porous host into a dense, impenetrable shield |

| Additives | Low-melting salts | Facilitates densification and protective encapsulation |

| Acid Resistance | High (e.g., 1 M HCl) | Prevents infiltration of corrosive chemical agents |

| Equipment | Muffle / Tube Furnace | Ensures uniform heating and precise thermal energy control |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is the difference between a porous failure and a stable masterpiece. KINTEK provides the advanced thermal technology needed for critical "pore-sealing" processes. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of your lab.

Whether you are developing ultra-stable perovskites or next-generation composites, our furnaces deliver the uniform temperature control required for perfect structural densification. Ready to optimize your research?

Visual Guide

References

- Qingfeng Li, Zhenling Wang. Improving the stability of perovskite nanocrystals <i>via</i> SiO<sub>2</sub> coating and their applications. DOI: 10.1039/d3ra07231b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What morphological changes occur in POMOF after treatment? Unlock High Catalytic Performance via Thermal Evolution

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights