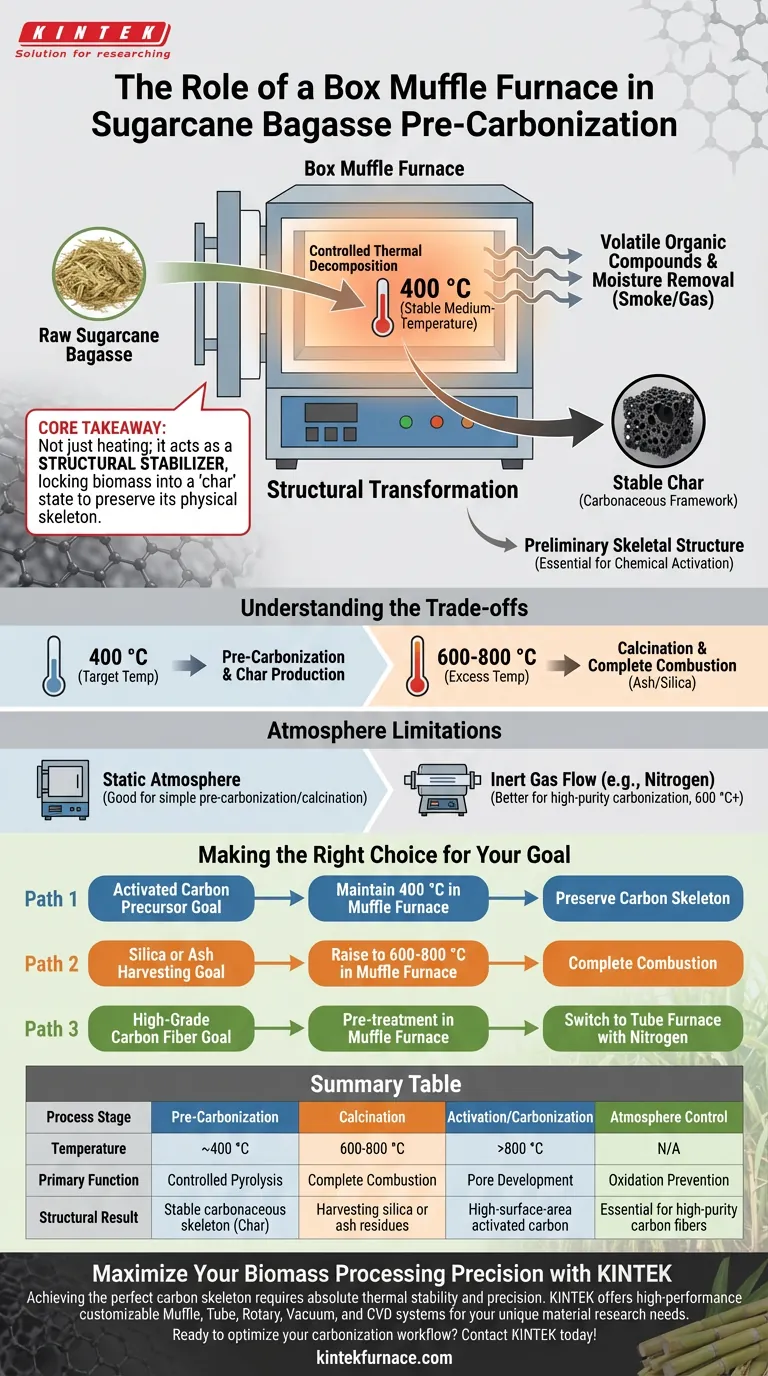

During the pre-carbonization stage, the box muffle furnace serves as the primary vessel for controlled thermal decomposition.

It maintains a stable, medium-temperature environment—specifically around 400 °C—to facilitate initial pyrolysis. By holding the sugarcane bagasse at this constant heat, the furnace drives off volatile organic compounds. This process converts the raw biomass into a stable char with a preliminary skeletal structure, which is essential for subsequent chemical activation.

Core Takeaway The box muffle furnace is not merely a heating element; it acts as a structural stabilizer. By removing volatiles at 400 °C, it locks the biomass into a "char" state, preserving the physical skeleton needed to create porous, high-surface-area carbon materials later in the process.

The Mechanics of Pre-Carbonization

Controlled Medium-Temperature Environment

The defining feature of the muffle furnace in this context is its ability to maintain a precise temperature plateau, typically at 400 °C.

This specific thermal range is critical because it is high enough to initiate breakdown but low enough to prevent complete combustion or structural collapse.

Removal of Volatile Matter

Raw sugarcane bagasse contains significant amounts of moisture and volatile organic components.

The furnace provides the sustained heat required to vaporize these non-carbon elements.

Removing these volatiles reduces the mass of the material while retaining the carbon-rich core.

Structural Transformation

Creation of the "Skeleton"

The most vital role of the furnace during this stage is the preservation of the material's physical architecture.

As volatiles exit the biomass, they leave behind a carbonaceous framework known as char.

This char retains a preliminary skeletal structure, which serves as the physical foundation for any future chemical activation or porosity development.

Preparation for Activation

This stage is a precursor to more aggressive processing.

Without this pre-carbonization step in the muffle furnace, subsequent chemical treatments would likely destroy the raw biomass.

The stabilized char provides a robust base that can withstand further modification without losing its structural integrity.

Understanding the Trade-offs

Temperature Sensitivity and Oxidation

While effective for pre-carbonization, the muffle furnace requires strict temperature management.

If the temperature exceeds the 400 °C target (approaching 600 °C - 800 °C), the process shifts from char production to calcination.

At these higher temperatures, especially without an inert atmosphere, the carbon burns off completely to form ash or silica, which defeats the purpose of creating carbon materials.

Atmosphere Limitations

Unlike tube furnaces, which pump inert gases (like nitrogen) directly over the sample, standard box muffle furnaces often have static atmospheres.

This makes them excellent for simple pre-carbonization or calcination, but less precise for high-purity carbonization required for advanced fiber production.

For processes requiring absolute protection from oxidation at higher temperatures (600 °C+), a tube furnace with a controlled nitrogen flow is generally preferred over a box muffle furnace.

Making the Right Choice for Your Goal

To optimize your processing of sugarcane bagasse, align your furnace usage with your specific end-material requirements:

- If your primary focus is creating an activated carbon precursor: Maintain the muffle furnace at 400 °C to strip volatiles while preserving the carbon skeleton.

- If your primary focus is harvesting silica or ash: Raise the muffle furnace temperature to between 600 °C and 800 °C to induce complete combustion and calcination.

- If your primary focus is high-grade carbon fiber: Use the muffle furnace only for pre-treatment, then switch to a tube furnace with a nitrogen atmosphere for the final high-temperature carbonization.

Success in biomass processing relies on using the pre-carbonization stage to stabilize the material's structure before attempting to enhance its properties.

Summary Table:

| Process Stage | Temperature | Primary Function | Structural Result |

|---|---|---|---|

| Pre-Carbonization | ~400 °C | Controlled Pyrolysis | Stable carbonaceous skeleton (Char) |

| Calcination | 600 - 800 °C | Complete Combustion | Harvesting silica or ash residues |

| Activation/Carbonization | > 800 °C | Pore Development | High-surface-area activated carbon |

| Atmosphere Control | N/A | Oxidation Prevention | Essential for high-purity carbon fibers |

Maximize Your Biomass Processing Precision with KINTEK

Achieving the perfect carbon skeleton requires more than just heat; it requires absolute thermal stability and precision. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique material research needs.

Whether you are producing activated carbon precursors or high-grade carbon fibers, our lab high-temp furnaces provide the reliability you need for consistent results.

Ready to optimize your carbonization workflow? Contact KINTEK today to discuss your custom furnace requirements with our specialists!

Visual Guide

References

- Kyfti Yolanda Siburian, Agung Nugroho. Effect of CoO loading on electrochemical properties of activated carbon from sugarcane bagasse. DOI: 10.5599/jese.2439

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What thermal processing applications do muffle furnaces have in pharmaceuticals? Essential for Purity and Quality Control

- Why is an industrial-grade burnout furnace required for enameled copper wire scrap? Ensure High Purity Copper Refining

- What is the primary function of a muffle furnace in CNM-Cl synthesis? Master Precision Thermal Polycondensation

- What role does a resistance furnace play in ZK61 magnesium alloy treatment? Mastering Homogenization & Microstructure

- What type of temperature control does the basic muffle furnace have? Discover Simple, Accurate Heating Solutions

- What materials are used for the cabinet of a box furnace and why? Discover Durable, Safe Steel Construction

- What customization options are available for muffle furnaces? Tailor Your Furnace for Peak Performance

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification