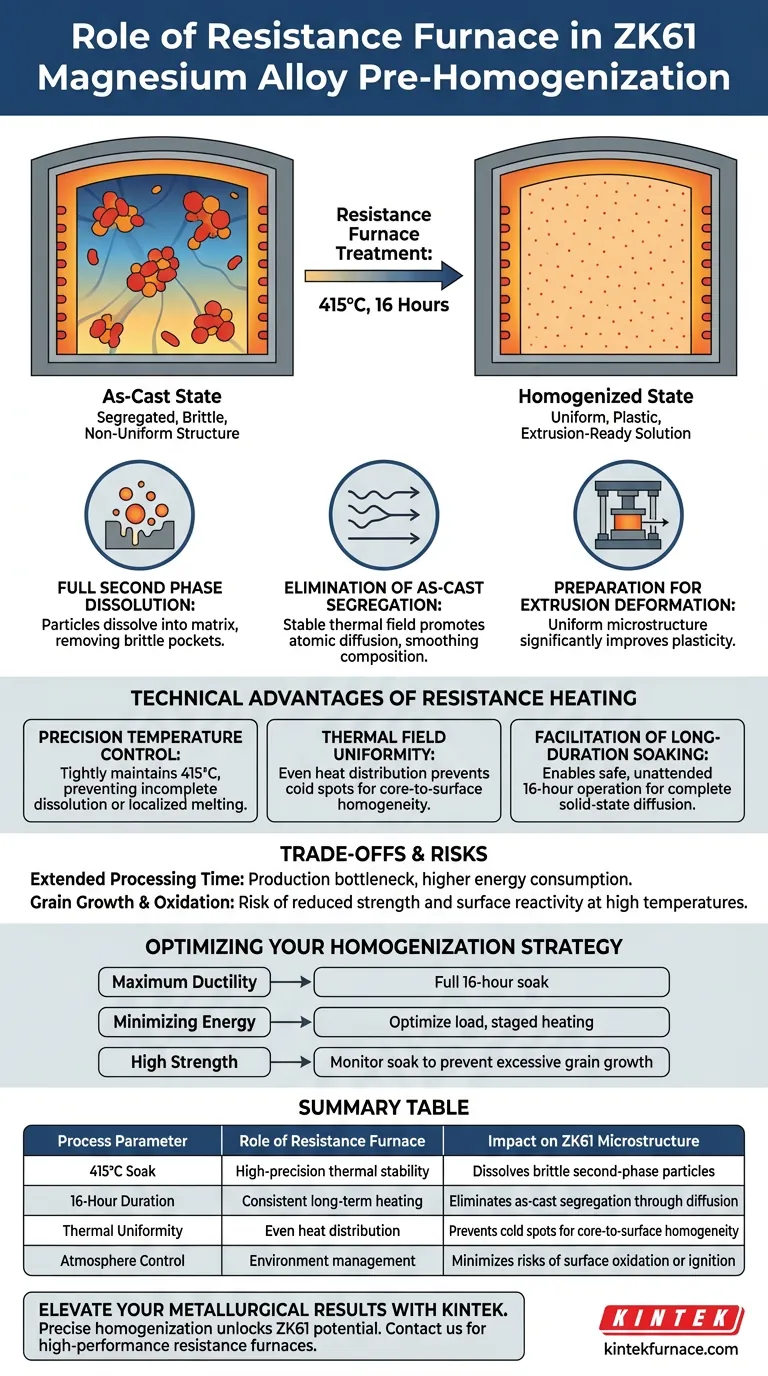

The resistance furnace serves as the critical thermal environment for dissolving secondary phases and eliminating structural defects in ZK61 magnesium alloy. By maintaining a constant temperature of approximately 415 °C for an extended duration—typically 16 hours—the furnace enables the full dissolution of the second phase into the alloy matrix. This process removes as-cast segregation and creates the uniform microstructural foundation required for successful subsequent extrusion deformation.

The core role of the resistance furnace in ZK61 processing is to facilitate a transition from a non-uniform as-cast state to a homogenized solid solution. This transformation is achieved through precise, long-term thermal stability that promotes atomic diffusion and phase dissolution.

The Mechanism of Microstructural Transformation

Achieving Full Second Phase Dissolution

The primary function of the furnace is to provide the energy necessary to break down the second phase particles that form during initial casting. At the target temperature of 415 °C, these particles migrate and dissolve into the magnesium matrix. This ensures that the alloying elements are distributed evenly rather than clustered in brittle pockets.

Elimination of As-Cast Segregation

During cooling after casting, magnesium alloys often suffer from compositional segregation, where elements are not distributed uniformly. The resistance furnace provides a stable thermal field that encourages atomic migration. Over a 16-hour period, this migration smooths out chemical gradients, resulting in a consistent material composition across the entire workpiece.

Preparation for Extrusion Deformation

Homogenization is a mandatory prerequisite for heavy mechanical working like extrusion. By creating a uniform microstructure, the furnace treatment improves the plasticity of the ZK61 alloy. Without this step, the material would likely crack or fail during the high-stress extrusion process due to internal structural inconsistencies.

Technical Advantages of Resistance Heating

Precision Temperature Control

Resistance furnaces utilize advanced control systems to maintain a tight temperature window. For ZK61, maintaining exactly 415 °C is vital; even slight deviations can lead to incomplete dissolution or, conversely, localized melting of low-temperature phases. This precision ensures repeatable results across different batches of material.

Thermal Field Uniformity

The design of the furnace chamber ensures that the thermal field is distributed evenly around the alloy. This uniformity is essential for preventing "cold spots" where segregation might persist. Every part of the ingot receives the same thermal energy, leading to a truly homogeneous microstructure from the surface to the core.

Facilitation of Long-Duration Soaking

The electrical nature of the resistance furnace allows for safe, unattended operation over the 16-hour soaking period. This long-term stability is necessary because diffusion in magnesium alloys is a time-dependent process. The furnace provides a reliable environment where the kinetics of solid-state diffusion can reach completion.

Understanding the Trade-offs

The Cost of Extended Processing Time

The requirement for a 16-hour soak time introduces a significant bottleneck in production. While necessary for quality, this long duration increases energy consumption and slows the overall manufacturing cycle. Engineers must balance the depth of homogenization with the economic realities of energy costs and throughput.

Risks of Grain Growth and Oxidation

Exposing magnesium alloys to high temperatures for long periods carries the risk of excessive grain growth, which can reduce the final strength of the part. Furthermore, magnesium is highly reactive at 415 °C. If the furnace atmosphere is not properly managed or if the temperature overshoots, there is a risk of surface oxidation or even ignition of the alloy.

Optimizing Your Homogenization Strategy

How to Apply This to Your Project

To achieve the best results with ZK61 magnesium alloy, your thermal treatment strategy should be dictated by the intended final use of the material and the specific dimensions of your casting.

- If your primary focus is Maximum Ductility for Complex Extrusion: Ensure a full 16-hour soak at 415 °C to guarantee the total elimination of brittle second-phase networks.

- If your primary focus is Minimizing Energy Consumption: Optimize the furnace load and consider staged heating to reach the homogenization temperature more efficiently without overshooting.

- If your primary focus is High Strength Post-Processing: Carefully monitor the soaking time to prevent excessive grain growth, which can compromise the Hall-Petch strengthening effect in the final product.

The resistance furnace is not merely a heater but a precision tool that dictates the metallurgical integrity and workable life of ZK61 magnesium alloys.

Summary Table:

| Process Parameter | Role of Resistance Furnace | Impact on ZK61 Microstructure |

|---|---|---|

| 415°C Soak | High-precision thermal stability | Dissolves brittle second-phase particles |

| 16-Hour Duration | Consistent long-term heating | Eliminates as-cast segregation through diffusion |

| Thermal Uniformity | Even heat distribution | Prevents cold spots for core-to-surface homogeneity |

| Atmosphere Control | Environment management | Minimizes risks of surface oxidation or ignition |

Elevate Your Metallurgical Results with KINTEK

Precise homogenization is the key to unlocking the full potential of ZK61 magnesium alloys. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance resistance furnaces—including Muffle, Tube, and Vacuum systems—engineered for the strict thermal stability required for long-duration soaking. Whether you need customizable dimensions or advanced atmosphere control to prevent oxidation, our high-temp lab solutions are designed to ensure your materials achieve maximum plasticity and structural integrity.

Ready to optimize your heat treatment process? Contact us today to discuss your unique project needs!

Visual Guide

References

- INFLUENCE OF EXTRUSION TEMPERATURE AND COOLING RATE ON THE MICROSTRUCTURE AND MECHANICAL PROPERTIES OF PRE-AGED EXTRUDED ZK61 Mg ALLOY. DOI: 10.17222/mit.2023.1025

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the primary function of a laboratory oven during the initial processing of geopolymer samples? Expert Guide

- What is the primary function of a high-temperature muffle furnace for cerium dioxide precursors? Expert Calcination Tips

- What are the alternative names for a muffle furnace? Discover Key Terms and Design Insights

- How do electrical muffle furnaces work? Unlock Precision Heating for Your Lab

- What role do muffle furnaces play in the pretreatment of medical samples? Essential for Accurate Elemental Analysis

- What is the purpose of using a high-temperature furnace at 900°C for eggshells? Master Calcination for CaO Production

- What are the main benefits of using muffle furnaces? Achieve Purity and Precision in Heat Treatment

- What role does a high-temperature laboratory muffle furnace play in Indium-doped LLZO? Optimize Solid Electrolyte Synthesis