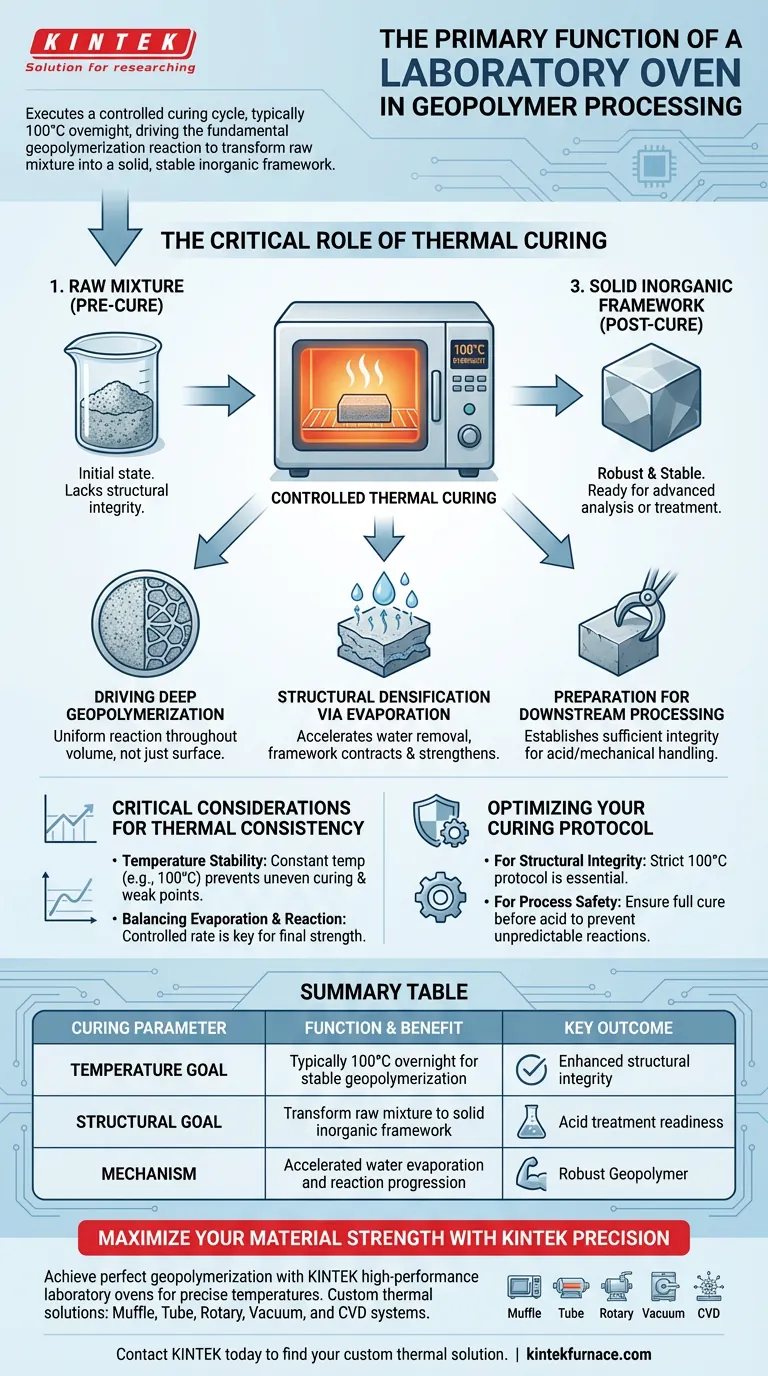

The primary function of a laboratory oven in geopolymer processing is to execute a controlled curing cycle. By maintaining a consistent temperature, typically 100°C overnight, the oven drives the fundamental geopolymerization reaction. This thermal environment is critical for transforming the raw mixture into a solid, stable inorganic framework.

The laboratory oven acts as a catalyst for structural development, ensuring the geopolymer achieves necessary rigidity through accelerated water evaporation and reaction progression. Without this controlled thermal phase, the inorganic framework would lack the integrity required for subsequent acid treatments or processing.

The Critical Role of Thermal Curing

Driving Deep Geopolymerization

The oven provides the thermal energy required to advance the chemical reaction beyond the surface level.

This deep progression ensures the material reacts uniformly throughout its volume, rather than just forming a superficial shell.

Structural Densification via Evaporation

Heat significantly accelerates the evaporation of free water contained within the sample mixture.

As water exits under controlled conditions, the inorganic framework contracts and strengthens, locking the chemical structure into a rigid state.

Preparation for Downstream Processing

The ultimate goal of this phase is to establish sufficient structural integrity.

Without this hardened state, the sample would likely degrade, crumble, or lose cohesion during harsh acid treatments or mechanical handling.

Critical Considerations for Thermal Consistency

The Importance of Temperature Stability

The success of this process relies heavily on maintaining a constant temperature (e.g., 100°C) throughout the duration of the cure.

Significant fluctuations in heat can lead to uneven curing, creating weak points or structural gradients within the sample.

Balancing Evaporation and Reaction

The curing process is a delicate balance between removing water and allowing time for the chemical structure to form.

If the environment is not controlled, removing water too aggressively before the reaction stabilizes can compromise the final strength of the framework.

Optimizing Your Curing Protocol

To ensure your geopolymer samples are correctly prepared for further analysis or treatment:

- If your primary focus is Structural Integrity: strict adherence to the 100°C overnight protocol is essential to fully establish the inorganic framework.

- If your primary focus is Process Safety: Ensure the sample is fully cured before introducing acid, as an under-cured sample may react unpredictably or dissolve.

Controlled thermal curing is the foundational step that transforms a reactive mixture into a robust geopolymer capable of enduring advanced processing.

Summary Table:

| Curing Parameter | Function & Benefit |

|---|---|

| Temperature Goal | Typically 100°C overnight for stable geopolymerization |

| Structural Goal | Transformations from raw mixture to solid inorganic framework |

| Mechanism | Accelerated water evaporation and thermal reaction progression |

| Key Outcome | Enhanced structural integrity and acid treatment readiness |

Maximize Your Material Strength with KINTEK Precision

Achieving perfect geopolymerization requires unwavering thermal stability. KINTEK provides high-performance laboratory ovens designed to maintain the precise temperatures necessary for critical curing cycles.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific research or production requirements. Ensure your samples achieve the structural integrity they deserve.

Contact KINTEK today to find your custom thermal solution.

Visual Guide

References

- Tuqa A. Jabar, Mayyadah S. Abed. Utilizing Kaolin-Based Geopolymer Catalysts for Improved Doura Vacuum Residue Cracking. DOI: 10.55699/ijogr.2024.0401.1061

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1200℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the common uses of a muffle furnace in material testing? Essential for Precise Thermal Analysis and Sample Prep

- Why is a muffle furnace essential for Sn:ZnO nanopowders? Achieve Perfect Crystal Structure and Purity

- What function does a muffle furnace serve in the synthesis of glass derived from rice husk ash? High-Temp Precision

- What are the primary applications of a laboratory muffle furnace? Achieve Precise, Contaminant-Free High-Temperature Processing

- How does a high-temperature muffle furnace facilitate the dual heat treatment of Ti0.96Nb0.04O2? Master Conductivity

- What role does a high-temperature electric furnace play in the conversion of raw kaolin into metakaolin? Expert Guide

- What role does a high-precision high-temperature box furnace play in the controlled foaming of aluminum? Key Insights

- What role does a laboratory box muffle furnace play in the synthesis of Nickel Oxide nanoparticles? Expert Insights