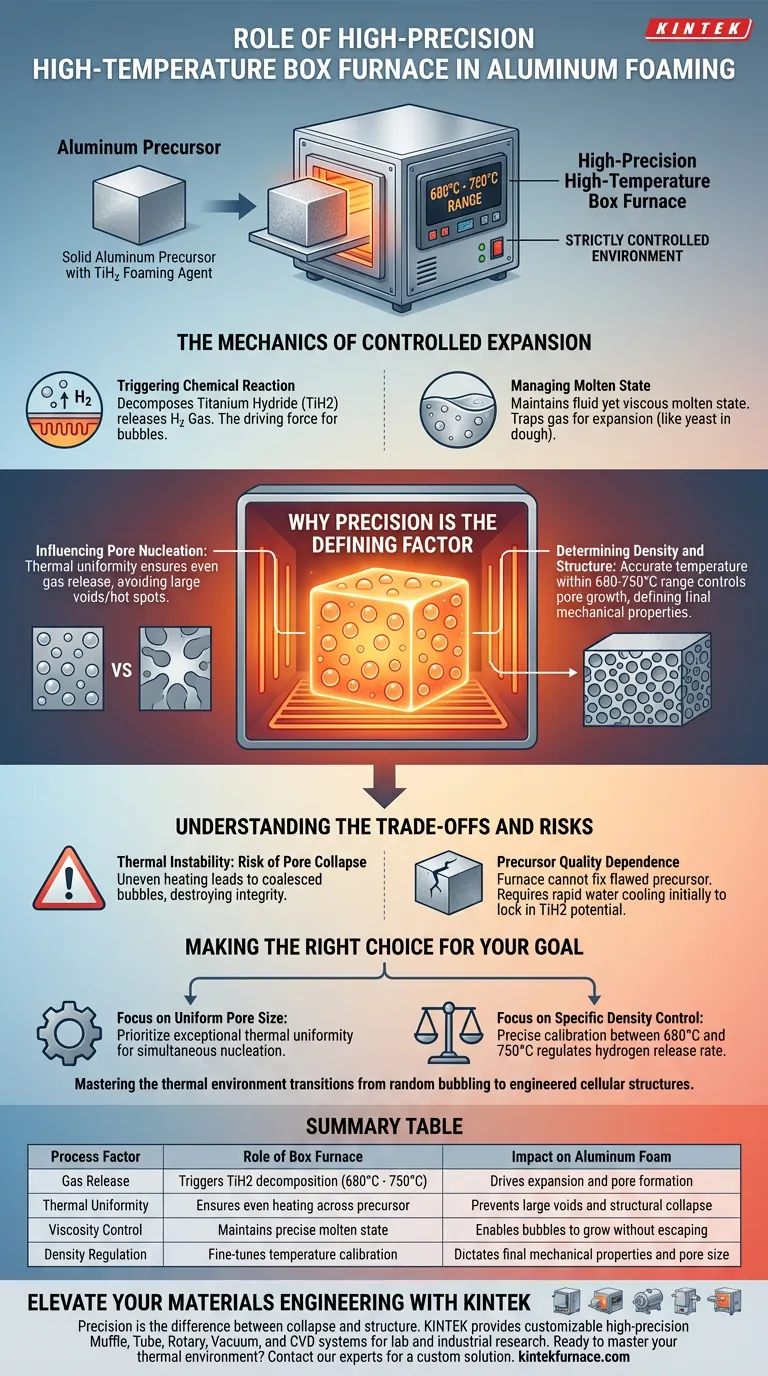

The high-precision high-temperature box furnace serves as the critical reaction vessel for transforming solid aluminum precursors into porous metallic foam. By maintaining a strictly controlled environment between 680°C and 750°C, the furnace triggers the thermal decomposition of the foaming agent (TiH2), releasing hydrogen gas that drives the expansion of the molten aluminum.

The success of aluminum foaming relies entirely on the precise synchronization of metal melting and gas release. The furnace’s primary value is not merely heating, but providing the thermal uniformity required to control pore nucleation and prevent structural collapse.

The Mechanics of Controlled Expansion

Triggering the Chemical Reaction

The fundamental role of the furnace is to initiate the decomposition of Titanium Hydride (TiH2).

As the furnace heats the precursor, the TiH2 releases hydrogen gas. This gas acts as the driving force, creating bubbles within the aluminum matrix to form a porous structure.

Managing the Molten State

The furnace must bring the aluminum to a molten state where it is fluid enough to expand but viscous enough to trap the gas.

If the environment is controlled correctly, the hydrogen expands the molten aluminum similarly to how yeast expands bread dough.

Why Precision is the Defining Factor

Influencing Pore Nucleation

High precision in temperature control directly dictates how and when pores begin to form (nucleation).

Temperature uniformity ensures that gas release occurs evenly throughout the material, rather than creating large voids in hot spots and dense sections in cool spots.

Determining Density and Structure

The specific temperature set within the 680°C to 750°C range controls the final density and pore size distribution of the foam.

Accurate control allows the operator to manipulate the "growth" phase of the pores, defining the material's final mechanical properties.

Understanding the Trade-offs and Risks

The Consequence of Thermal Instability

If the furnace fails to maintain uniformity, you risk pore collapse.

Uneven heating can cause bubbles to coalesce (merge into large, weak voids) or escape entirely, destroying the foam's structural integrity.

Precursor Quality Dependence

While the furnace controls expansion, it cannot fix a flawed precursor.

The precursor must have undergone rapid water cooling during its initial creation to lock in the TiH2 foaming potential; without this "frozen" potential, even the best furnace cannot achieve controlled foaming.

Making the Right Choice for Your Goal

To optimize your aluminum foaming process, align your furnace operations with your specific material objectives:

- If your primary focus is Uniform Pore Size: Prioritize a furnace with exceptional thermal uniformity to ensure simultaneous nucleation across the entire sample.

- If your primary focus is Specific Density Control: Focus on the precise calibration of temperature between 680°C and 750°C to strictly regulate the rate of hydrogen release.

Mastering the thermal environment is the only path to transitioning from random bubbling to engineered cellular structures.

Summary Table:

| Process Factor | Role of Box Furnace | Impact on Aluminum Foam |

|---|---|---|

| Gas Release | Triggers TiH2 decomposition (680°C - 750°C) | Drives expansion and pore formation |

| Thermal Uniformity | Ensures even heating across the precursor | Prevents large voids and structural collapse |

| Viscosity Control | Maintains precise molten state | Enables bubbles to grow without escaping |

| Density Regulation | Fine-tunes temperature calibration | Dictates final mechanical properties and pore size |

Elevate Your Materials Engineering with KINTEK

Precision is the difference between a failed collapse and a perfect cellular structure. At KINTEK, we understand the rigorous demands of aluminum foaming and advanced metallurgy.

Backed by expert R&D and manufacturing, we provide high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your specific thermal uniformity and density control needs. Whether you are conducting lab-scale research or industrial production, our high-temperature lab furnaces ensure your precursors transform into superior engineered materials.

Ready to master your thermal environment? Contact our experts today to find your custom solution.

Visual Guide

References

- Xiaotong Lu, Xiaocheng Li. Pore Structure and Deformation Correlation of an Aluminum Foam Sandwich Subject to Three-Point Bending. DOI: 10.3390/ma17030567

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What materials are used in the construction of muffle furnaces? Key Components for High-Temp Performance

- What are the common applications of box furnaces? Versatile Heat Treatment for Metals, Ceramics, and Research

- What should be considered regarding the working temperature of a muffle furnace? Ensure Precision and Longevity for Your Lab

- What is the function of a Muffle Furnace in the pre-treatment of Ni-Fe-Cu alloy anodes? Achieve Superior Corrosion Resistance

- What are some critical 'Don'ts' when operating a muffle furnace? Avoid Explosions and Damage

- What is the purpose of an ashing furnace? Essential for Accurate Ash Content Analysis

- What is the role of a high-temperature muffle furnace in Mg-Zn-Al LDH transformation? Unlocking Adsorption Power

- What advanced features do muffle furnaces include? Boost Precision and Safety in Your Lab